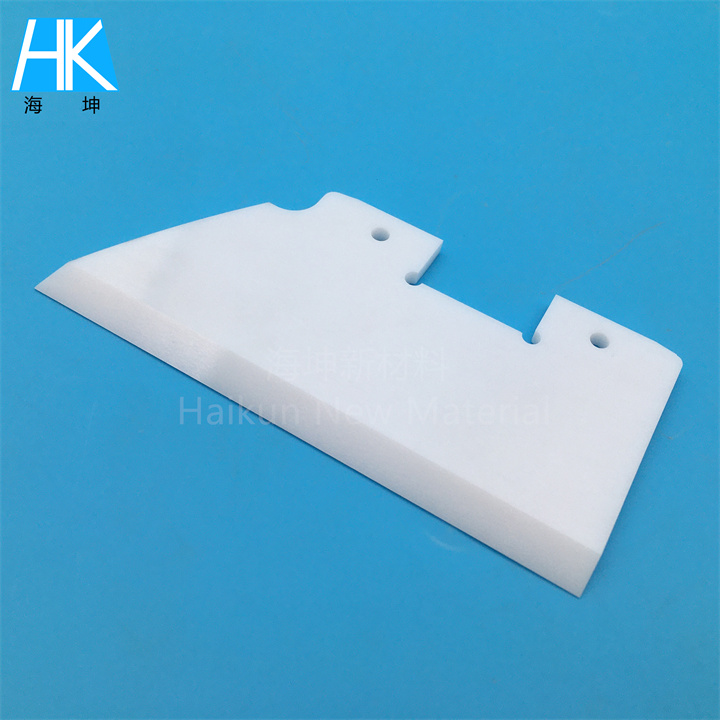

Zirconia Ceramic Cutting Blade Knife for Industry Use

-

$2.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangdong, Dongguan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000pcs/month |

| Supply Ability: | 1000000pcs/month |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,Express Delivery,EXW,CPT |

| Certificate: | ISO9001 |

| HS Code: | 8547100000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangdong,Dongguan |

Zirconia ceramic cutting blades, often utilized in the industry due to their exceptional properties, offer unparalleled performance and durability. These blades are made from zirconia, a material renowned for its high hardness, resistance to wear, and excellent thermal stability. Here's an overview of what makes these cutting blades unique and how they can be beneficial in various industrial applications.

### Key Features of Zirconia Ceramic Cutting Blades

1. **High Hardness**: Zirconia ceramics have a Mohs hardness rating that rivals that of diamond, making them extremely resistant to scratching and chipping. This characteristic allows them to maintain their sharpness for longer periods compared to traditional metal cutting tools.

2. **Heat Resistance**: Due to their high melting point, zirconia ceramic blades can withstand high temperatures without losing their structural integrity or degrading. This feature is particularly advantageous in applications involving high heat, such as metal cutting, woodworking, and glass processing.

3. **Precision Cutting**: The high accuracy and smooth cutting action provided by zirconia ceramic blades make them ideal for precision tasks. They can cut through materials with minimal deformation, ensuring clean edges and reduced waste.

4. **Longevity**: Because of their strength and resistance to wear, zirconia ceramic blades last significantly longer than conventional cutting tools. This longevity reduces maintenance costs and downtime, enhancing productivity in manufacturing environments.

5. **Environmental Friendliness**: Compared to other materials like carbide or diamond, zirconia ceramics produce less dust during cutting operations, which is beneficial for both the operator’s health and the environment. Additionally, they do not require the use of lubricants, further reducing environmental impact.

6. **Versatility**: Zirconia ceramic blades can be used on a wide range of materials, including metals, plastics, and composites. Their versatility makes them suitable for various industries, from automotive and aerospace to construction and electronics.

Applications in Industry

- **Metal Cutting**: Used in metal fabrication, sheet metal processing, and die cutting.

- **Woodworking**: Ideal for cutting hardwood, plywood, and other wood-based materials.

- **Glass Processing**: Precise cutting of glass panels for manufacturing windows, mirrors, and other glass products.

- **Electronics Manufacturing**: Sensitive electronic components require precise cuts without causing damage, making zirconia ceramic blades a preferred choice.

- **Aerospace Industry**: High-quality cuts are crucial in the aerospace industry for components requiring extreme precision and durability.

Conclusion

Zirconia ceramic cutting blades represent a significant advancement in industrial cutting technology. Their combination of high hardness, heat resistance, precision, and long-lasting durability makes them a valuable asset in a variety of industries. Whether it's enhancing efficiency in production lines or improving the quality of finished products, zirconia ceramic blades offer a superior solution compared to traditional cutting tools.\

Dongguan Haikun New Material Co., Ltd which manufactures a variety of customized precision machining industrial ceramic parts' solutions more than 17 years.

The main advanced ceramics materials used the make the industrial ceramic parts include Zirconia, Alumina, Silicon Nitride, Macor, Silicon Carbide,Boron Nitride, etc.

Our customized ceramic parts are widely used in machinery, semi-conductors,aerospace, aviation, military, nuclear power, textile, chemical, electronic, food, medical, petroleum,etc.

Welcome your inquiry! What’sapp/Wechat: +86-13823242056