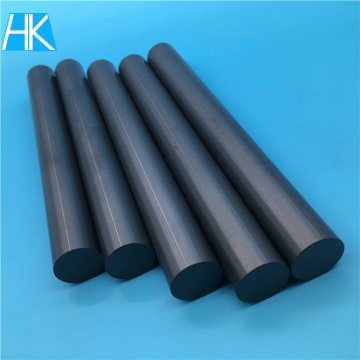

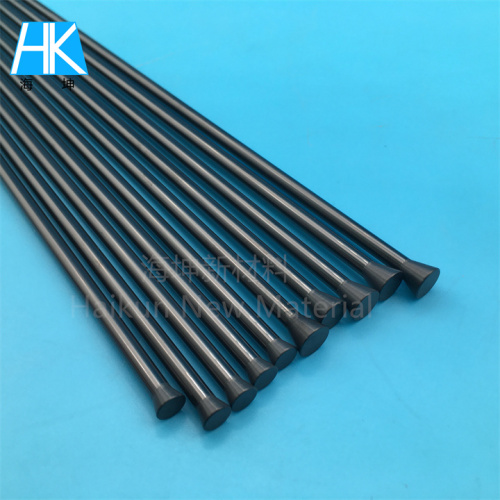

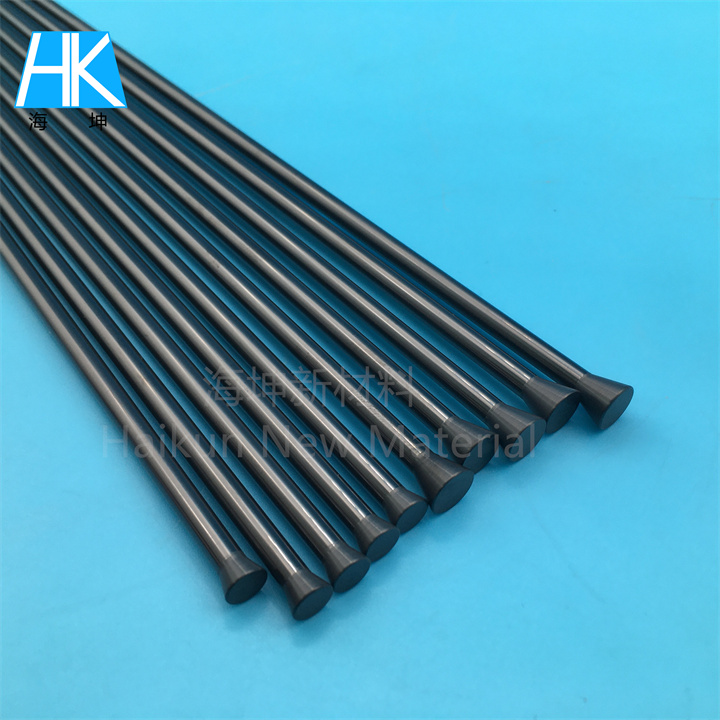

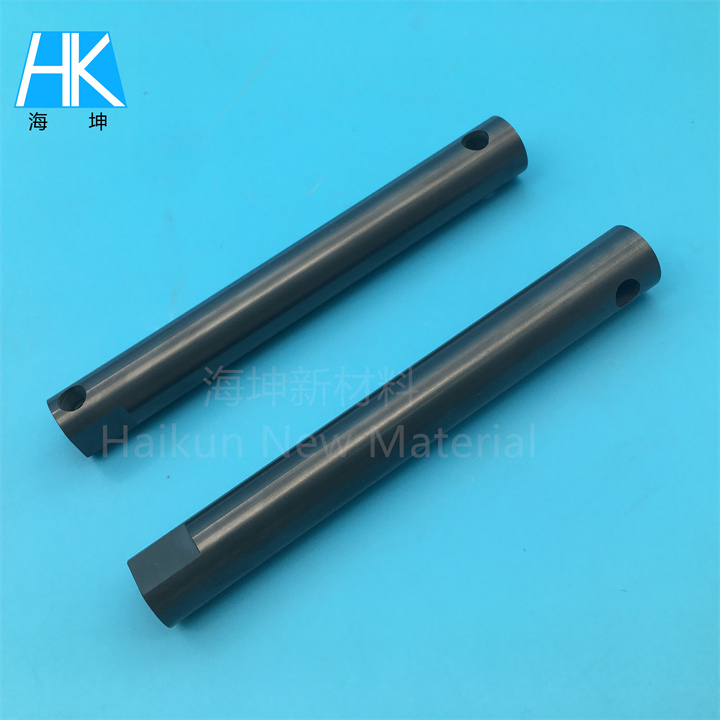

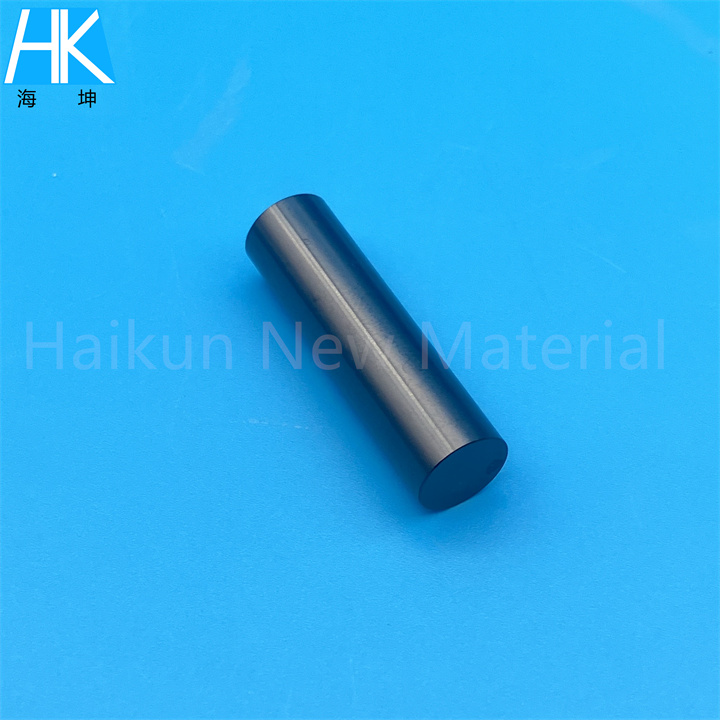

Silicon Nitride Si3n4 Ceramic Roller Rod

-

$2.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangdong, Dongguan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000pcs/month |

| Supply Ability: | 1000000pcs/month |

| Payment Type: | T/T,Paypal,Alipay |

| Incoterm: | FOB,DDU,Express Delivery,CFR,CIF,EXW,CPT,CIP,DDP |

| Certificate: | ISO9001 |

| HS Code: | 8547100000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangdong,Dongguan |

What's is Silicon Nitride Ceramic ?

Silicon Nitride (Si3N4) has the most versatile combination of mechanical, thermal and electrical properties of any advanced ceramic material. It is a high-performance advanced ceramic that is extremely hard and has excellent thermal shock and impact resistance. It exceeds the high-temperature capabilities of most metals and has excellent creep and oxidation resistance. In addition, its low thermal conductivity and high wear resistance make it an excellent material for withstanding the harshest conditions in the most demanding industrial applications. Silicon nitride is an excellent choice when high temperatures and high load capacity are required.

Silicon Nitride Ceramic rods are cylindrical components made from silicon nitride, a high-performance engineering ceramic material. Here are some key points about silicon nitride ceramic rods:

1. Composition: Primarily composed of silicon nitride (Si3N4), with possible additions of sintering aids like yttrium oxide (Y2O3) or aluminum oxide (Al2O3).

2. Properties:

- Exceptional hardness and wear resistance

- High temperature strength and stability

- Good thermal shock resistance

- Excellent chemical corrosion resistance

- Low thermal expansion coefficient

- High electrical resistivity

3. Applications:

- Aerospace components

- Automotive parts (e.g., engine components)

- Industrial machinery and tools

- Medical devices

- Semiconductor manufacturing equipment

4. Manufacturing process:

Typically produced using advanced ceramic fabrication techniques such as:

- Reaction Bonded Silicon Nitride (RBSN)

- Hot Pressing

- Sintering with additives

- Gas Pressure Sintering

5. Sizes and dimensions:

Available in various lengths, diameters, and tolerances to meet specific application requirements.

6. Surface finishes:

Can be provided with different surface roughnesses, from ground to highly polished finishes.

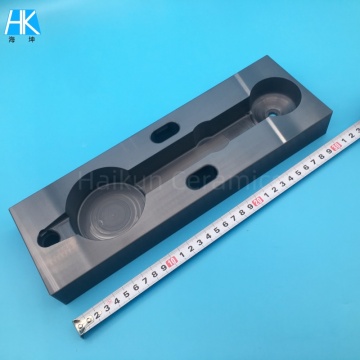

7. Customization:

Often available in custom sizes and shapes to meet specific design needs.

8. Advantages over metal counterparts:

Lighter weight, higher temperature capability, better corrosion resistance, and longer service life in many applications.

When specifying silicon nitride ceramic rods, it's important to consider factors like operating temperature, mechanical loads, environmental conditions, and desired service life to select the most appropriate grade and configuration for your application.

Dongguan Haikun New Material Co., Ltd which manufactures a variety of customized precision machining industrial ceramic parts' solutions more than 17 years.

The main advanced ceramics materials used the make the industrial ceramic parts include Zirconia, Alumina, Silicon Nitride, Macor, Silicon Carbide,Boron Nitride, etc.

Our customized ceramic parts are widely used in machinery, semi-conductors,aerospace, aviation, military, nuclear power, textile, chemical, electronic, food, medical, petroleum,etc.

If you have the custom Silicon Nitride Ceramic roller rod request, pls feel free to contact with us! What’sapp/Wechat: +86-13823242056