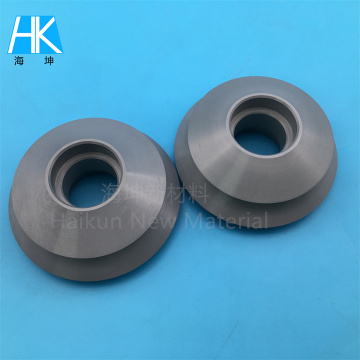

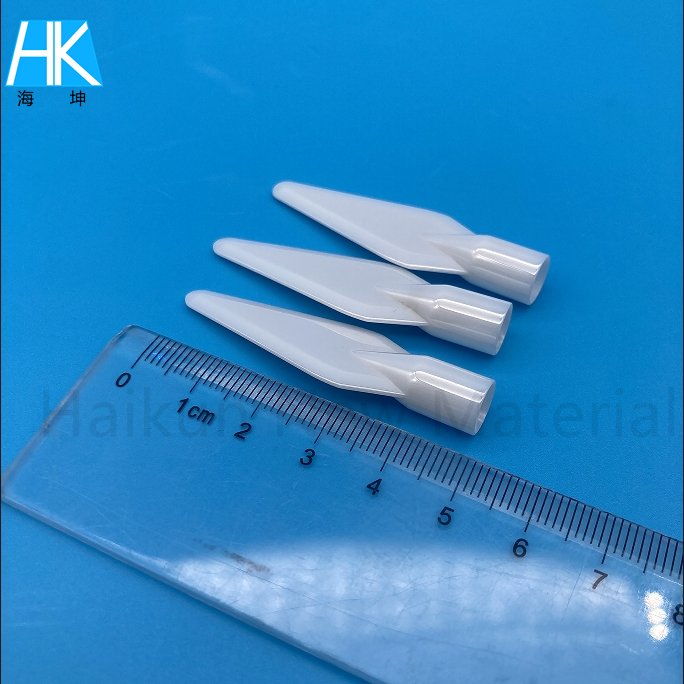

Injection Molding Zirconium Oxide Industrial Ceramic Parts

-

$0.50≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Air, Express

- Port:

- Shenzhen, Guangdong, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000pcs/month |

| Supply Ability: | 1000000pcs/month |

| Payment Type: | T/T,Paypal,Alipay |

| Incoterm: | FOB,CFR,CIF,EXW,CPT,DDP,DDU,Express Delivery |

| Certificate: | ISO9001 |

| HS Code: | 8547100000 |

| Transportation: | Ocean,Air,Express |

| Port: | Shenzhen,Guangdong,Shenzhen |

What's the Zirconium Oxide Ceramic?

Zirconium oxide ceramics are white, yellow or gray when containing impurities, and generally contain HfO 2, which is not easily separated. Pure ZrO2 has three crystal states under normal pressure. The production of zirconia ceramics requires the preparation of high-purity, good dispersion properties, ultra-fine particles, narrow particle size distribution, zirconia ultrafine powder preparation methods, zirconia purification mainly chlorination and thermal decomposition, alkali metal Oxidative decomposition method, lime melting method, plasma arc method, precipitation method, colloid method, hydrolysis method, spray pyrolysis etc.

In terms of structural ceramics, zirconia ceramics are widely used in the field of structural ceramics because of their high toughness, high flexural strength and high wear resistance, excellent thermal insulation properties, and thermal expansion coefficient close to that of steel. Mainly: Y-TZP grinding ball, dispersion and grinding media, nozzle, ball valve ball seat, zirconia mold, micro fan shaft, fiber pin, fiber sleeve, wire drawing die and cutting tool, wear-resistant tool, clothing button, Cases and straps, bracelets and pendants, ball bearings, golf ball hitters and other room temperature wear-resistant components.

Zirconium Oxide Ceramic Properties:

High strength, high hardness, crash resistance, wear resistance, corrosion resistance, smooth surface, low thermal conductivity, nonmagnetic etc.

Application industry: Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

Injection molding is a manufacturing process used to produce parts from plastic, metal, or ceramic materials. When it comes to zirconia ceramic structural parts, the injection molding process involves shaping the zirconia material into precise and complex forms.

Dongguan Haikun New Material Co., Ltd which manufactures a variety of customized precision machining industrial ceramic parts' solutions more than 17 years.

The main advanced ceramics materials used the make the industrial ceramic parts include Zirconia, Alumina, Silicon Nitride, Macor, Silicon Carbide,Boron Nitride, etc.

Our customized ceramic parts are widely used in machinery, semi-conductors,aerospace, aviation, military, nuclear power, textile, chemical, electronic, food, medical, petroleum,etc.

Welcome your inquiry! What’sapp/Wechat: +86-13823242056

Related Keywords