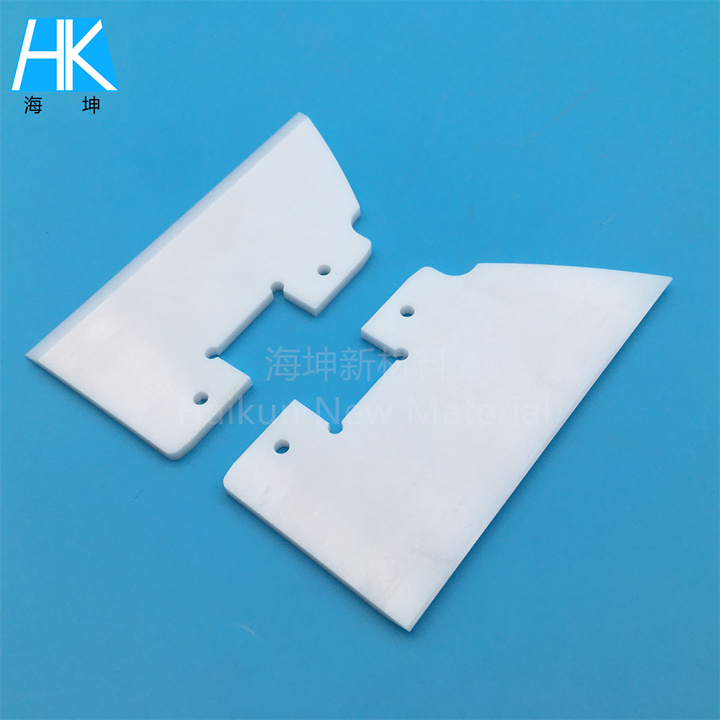

Insulating Wear Resistance Zirconia Ceramic Parts

-

$2.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Land, Ocean, Air, Express

- Port:

- Shenzhen, Guangdong, Dongguan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000pcs/month |

| Supply Ability: | 1000000pcs/month |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,CPT,Express Delivery |

| Certificate: | ISO9001 |

| HS Code: | 8547100000 |

| Transportation: | Land,Ocean,Air,Express |

| Port: | Shenzhen,Guangdong,Dongguan |

What is Zirconia Ceramic Parts?

Zirconia ceramic parts are highly sought after in industries that require components with exceptional insulating and wear-resistant properties. These parts are typically made from zirconia, a form of zirconium dioxide (ZrO2), which is known for its high melting point, thermal stability, and mechanical strength. Here’s how these ceramic parts achieve their unique characteristics:

Insulating Properties

- **High Dielectric Constant**: Zirconia ceramics have a high dielectric constant, making them effective insulators. This property allows them to resist the flow of electric current, which is crucial in applications like capacitors and electrical insulation in high-voltage systems.

- **Low Conductivity**: The low electrical conductivity of zirconia ceramics ensures minimal energy loss during electrical transmission, making them ideal for use in high-frequency circuits and devices.

Wear Resistance

- **High Hardness**: Zirconia ceramics are exceptionally hard, often exceeding the hardness of steel. This hardness translates into superior wear resistance, which is vital in applications where components are subjected to continuous friction or impact.

- **Tough Microstructure**: The microstructure of zirconia ceramics can be engineered to contain tough grains that can absorb and redistribute stress, enhancing the material's resistance to wear and tear.

Applications

Zirconia ceramic parts find applications across various sectors due to their combined insulating and wear-resistant properties:

1. **Electronics**: In capacitors, electrical insulation, and high-voltage switches where both electrical insulation and mechanical durability are critical.

2. **Automotive Industry**: For engine components, such as turbocharger wheels, where high temperature resistance and wear resistance are required.

3. **Medical Devices**: In implants and surgical tools, where biocompatibility, durability, and resistance to wear are essential.

4. **Energy Sector**: In turbine blades, heat exchangers, and other components exposed to high temperatures and mechanical stresses.

5. **Industrial Machinery**: For components in pumps, bearings, and other mechanical systems that need to withstand harsh conditions without degrading quickly.

Zirconia Ceramic Manufacturing Processes

Zirconia ceramic parts are typically produced through advanced manufacturing techniques such as:

- **Sintering**: A process where the ceramic powder is heated to high temperatures to fuse the particles together.

- **Additive Manufacturing (AM)**: Also known as 3D printing, this method allows for the creation of complex shapes and structures that might be difficult or impossible to produce using traditional manufacturing methods.

The combination of these properties makes zirconia ceramic parts indispensable in numerous high-demand applications, offering solutions that are both efficient and durable.

Dongguan Haikun New Material Co., Ltd which manufactures a variety of customized precision machining industrial ceramic parts' solutions more than 17 years.

The main advanced ceramics materials used the make the industrial ceramic parts include Zirconia, Alumina, Silicon Nitride, Macor, Silicon Carbide,Boron Nitride, etc.

Our customized ceramic parts are widely used in machinery, semi-conductors,aerospace, aviation, military, nuclear power, textile, chemical, electronic, food, medical, petroleum,etc.

Welcome your inquiry! What’sapp/Wechat: +86-13823242056

Related Keywords