Precise Machining Zirconia Ceramic Impeller Rotor for Pump

-

$1.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangdong, Dongguan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000pcs/month |

| Supply Ability: | 1000000pcs/month |

| Payment Type: | T/T,Paypal,Alipay |

| Incoterm: | CFR,CIF,EXW,CPT,DDP,CIP,Express Delivery |

| Certificate: | ISO9001 |

| HS Code: | 8547100000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangdong,Dongguan |

We have been offering a selection of partially stabilized zirconia, including Y-TZP( yttria-stabilized), MSZ ( magnesia stabilized ). Each stabilized zirconia provides unique and specific properties that meet the demands of extreme applications found in many industries.

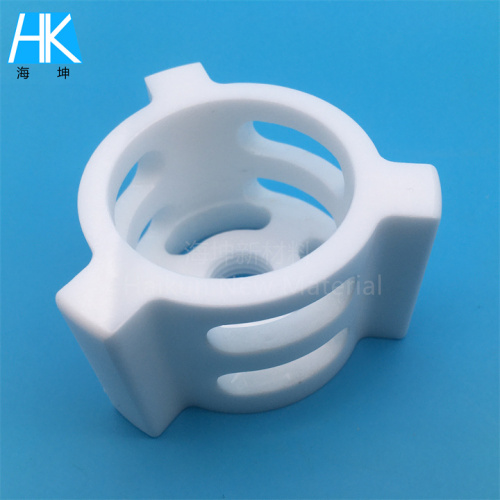

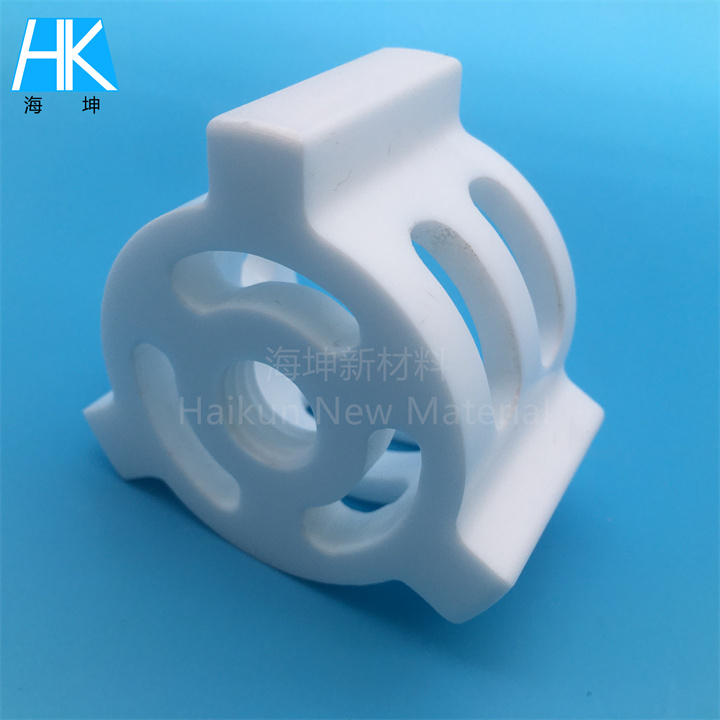

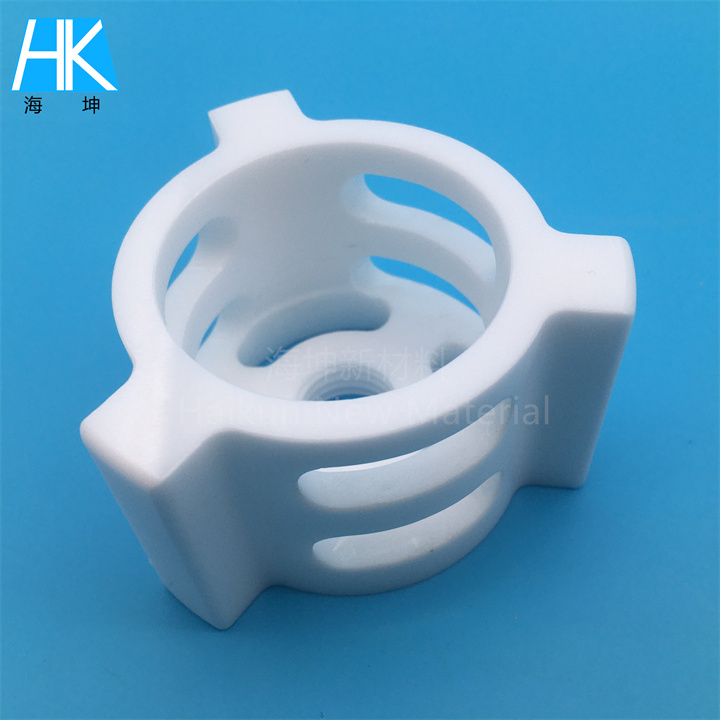

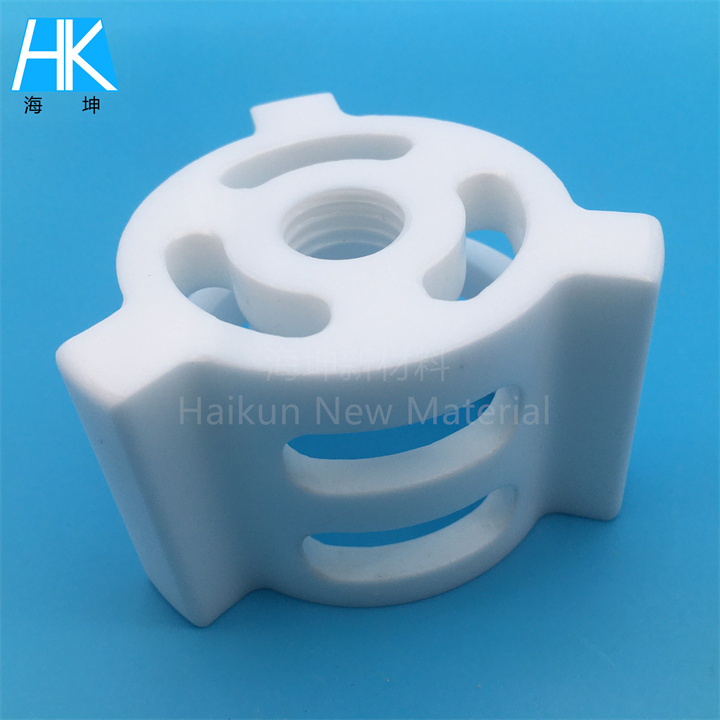

Main features of zirconia ceramic parts, zirconia ceramic impeller

1. High density: more than 6 g/cm3, is the main body of ceramic products with the highest density.

2. High hardness: more than 9 on Mohs scale, 10 on diamond, with smooth surface like satin.

3. High toughness: more than 1200 MPa, about 4 times that of 95% alumina. 4.

4. Excellent abrasion resistance, better than alumina ceramics, longer service life 5.

5. Low thermal conductivity: less than 3 W/m.k at ambient temperature, ideal for thermal conductivity. 6. 6.

6. Good chemical and corrosion resistance, equivalent to more than 99% of aluminum oxide.

The description of zirconia ceramic impeller rotars:

The frequency of pump maintenance affects the efficiency of the pump and therefore it is necessary to select structural components for the pump that are made from wear resistant, durable and corrosion resistant materials.

Unlike coated finishes, however, zirconia is a solid ceramic that provides a consistent and uniform wear rate, making it very easy for engineers to perform regular and planned maintenance.

Ceramic structural components for pumps, such as ceramic impellers, ceramic liners, ceramic valves and ceramic bushings, are the most commonly used alternatives to metal components for pumping sandy oils. We can customize the production of ceramic valve components according to customer's structural design and technical drawings. For customized production, please contact us for more information.

Dongguan Haikun New Material Co., Ltd which manufactures a variety of customized precision machining industrial ceramic parts' solutions more than 17 years.

Welcome your inquiry! What’sapp/Wechat: +86-13823242056

Related Keywords