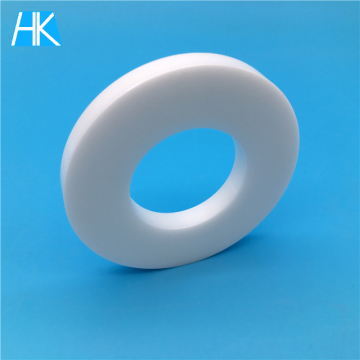

Yttria-stabilized Zirconia Zro2 Ceramic Ring Bearing

-

$2.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Dongguan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000pcs/month |

| Supply Ability: | 1000000pcs/month |

| Payment Type: | T/T,Paypal,Alipay |

| Incoterm: | FOB,Express Delivery,CFR,CIF,EXW,CPT,CIP,DDP |

| Certificate: | ISO9001 |

| HS Code: | 8547100000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Dongguan |

1. **Material Properties**:

- **High Hardness**: Zirconia has excellent hardness properties, making it highly resistant to wear.

- **Chemical Stability**: It is chemically inert, providing good corrosion resistance.

- **Thermal Stability**: It can operate at high temperatures without significant degradation.

- **Low Thermal Conductivity**: This property helps in maintaining temperature stability within the bearing.

2. **Applications**:

- **Precision Instruments**: Used in precision instruments and equipment where accuracy and long-term reliability are critical.

- **Medical Devices**: Due to its biocompatibility and durability, zirconia is often used in medical devices.

- **Aerospace**: For applications requiring lightweight, durable, and high-performance materials.

- **Automotive**: In high-performance engines or other components that require low friction and high wear resistance.

3. **Design and Manufacturing**:

- **Ceramic Rings**: These bearings are typically made from ceramic rings with precision-machined surfaces for smooth operation.

- **Assembly**: They may be assembled with other components such as retainers or cages depending on the application requirements.

- **Surface Finishing**: High-quality surface finishing is crucial to ensure minimal friction and optimal performance.

4. **Advantages**:

- **Long Service Life**: Due to its wear-resistant nature, these bearings can last longer than their metal counterparts.

- **Low Maintenance**: Reduced need for lubrication and maintenance.

- **Lightweight**: Being lighter than metal bearings, they can reduce the overall weight of machinery.

5. **Challenges**:

- **Cost**: Ceramic bearings can be more expensive than metal ones.

- **Brittleness**: While very hard, ceramics can be brittle under certain conditions.

- **Impact Resistance**: Requires careful handling and design to avoid impact damage.

If you have specific questions about the use, design, or application of zirconia ZrO₂ ceramic ring bearings, feel free to ask!

Dongguan Haikun New Material Co., Ltd which manufactures a variety of customized precision machining industrial ceramic parts' solutions more than 17 years.

The main advanced ceramics materials used the make the industrial ceramic parts include Zirconia, Alumina, Silicon Nitride, Macor, Silicon Carbide,Boron Nitride, etc.

Our customized ceramic parts are widely used in machinery, semi-conductors,aerospace, aviation, military, nuclear power, textile, chemical, electronic, food, medical, petroleum,etc.

Welcome your inquiry! What’sapp/Wechat: +86-13823242056

Related Keywords