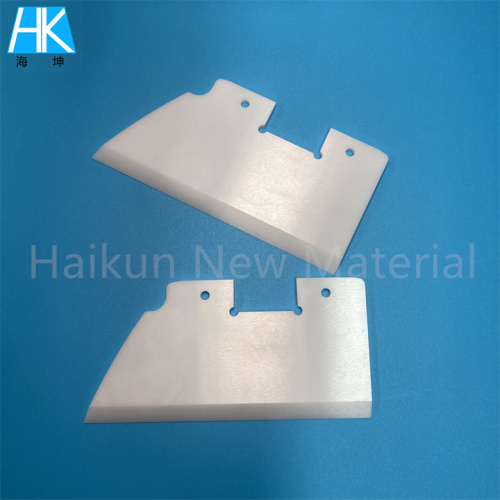

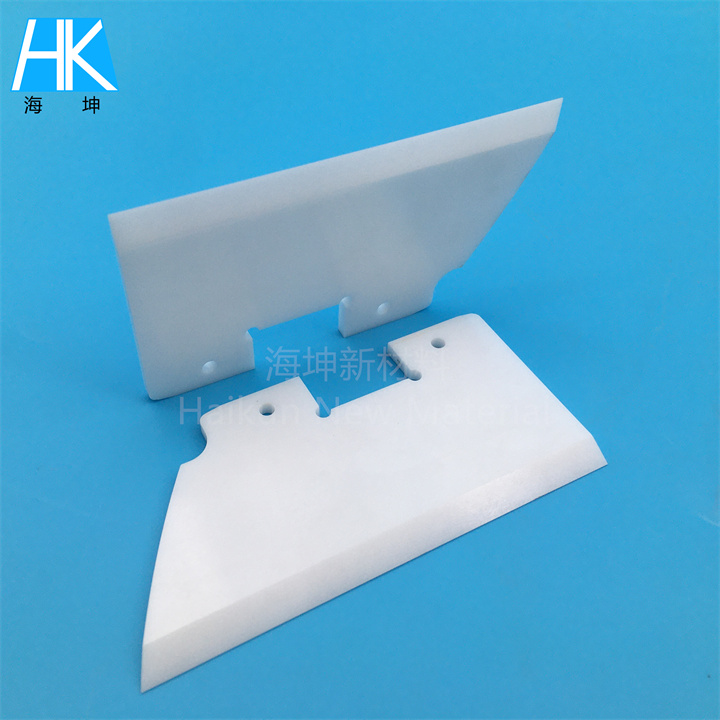

Polished ZrO2 Zirconia Ceramic Blade Cutting Knife

-

$8.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Dongguan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000pcs/month |

| Supply Ability: | 10000pcs/month |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,CPT,Express Delivery |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Dongguan |

What is zirconia ceramic?

Zirconia ceramic is a very strong technical ceramic that offers high strength, fracture toughness, flexibility, wear and corrosion resistance.

Zirconia Ceramic Blade

Zirconia ceramic blades are high-performance cutting tools that offer superior cutting efficiency, durability, and resistance to wear and tear compared to traditional metal blades. They are made from zirconia, a type of ceramic material that is known for its high strength and toughness.

Here are some key features and benefits of zirconia ceramic industrial blades:

1. High Hardness: Zirconia ceramics have a higher hardness than steel, which makes them very effective at cutting through hard materials such as metal, glass, and stone without dulling quickly.

2. Durability: Due to their high strength and resistance to wear, zirconia ceramic blades can maintain their sharpness over a long period, reducing the need for frequent sharpening or replacement.

3. Cutting Efficiency: These blades are designed to cut through materials with minimal friction, which not only speeds up the cutting process but also reduces heat generation and the risk of overheating, making them suitable for continuous cutting operations.

4. Precision Cutting: Zirconia ceramic blades provide precise cuts due to their excellent thermal stability, ensuring consistent performance even when subjected to high temperatures during cutting processes.

5. Environmentally Friendly: Unlike traditional metal blades that may require frequent replacements and the use of sharpening tools, zirconia ceramic blades can last longer, potentially reducing waste and environmental impact.

6. Safety: They are less likely to break under pressure compared to metal blades, which can be dangerous in industrial settings. Additionally, since they do not rust, they reduce the risk of corrosion-related accidents.

7. Versatility: Zirconia ceramic industrial blades are used in various industries including manufacturing, construction, and automotive, where precision and durability are crucial.

When selecting zirconia ceramic industrial blades, it's important to consider factors such as blade size, shape, and the specific material being cut to ensure optimal performance and longevity. Regular maintenance and storage practices can also help prolong the life of these blades.

Dongguan Haikun New Material Co.,Ltd supply high precision zirconia ceramic industrial blade for customer's request. Welcome your request!

Products Show

Zirconia Ceramic Machining Manufacturing Process

2. High quality products with low price

3. High precision parts with lowest tolerance

4. Show time for production

5. Has a group of experienced, professional and efficient R&D team

6. Has a good reputation in China and abroad.

7. MOQ is not limited, small quantity is welcome.

8. Vigorous team and good after-sales service