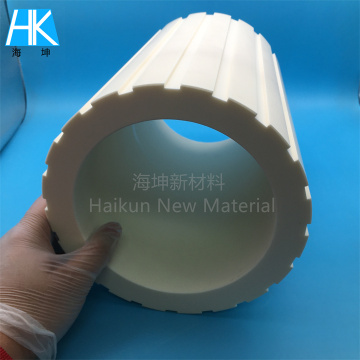

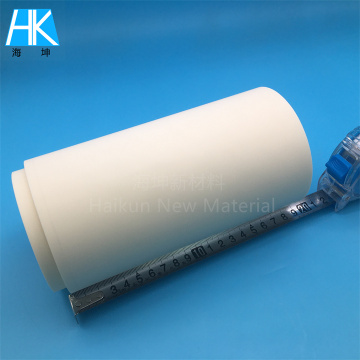

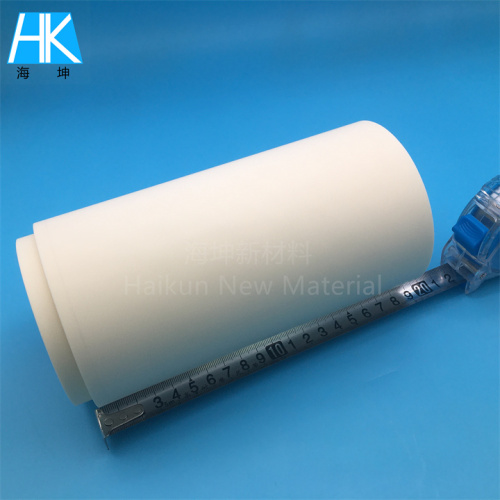

Refractory CNC Machining 99% Alumina Ceramic Tube Cylinder for Pump

-

$3.00≥2 Piece/Pieces

- Min. Order:

- 2 Piece/Pieces

- Min. Order:

- 2 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Dongguan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000pcs/month |

| Supply Ability: | 100000pcs/month |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,CPT,Express Delivery |

| Certificate: | ISO9001 |

| HS Code: | 8547100000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Dongguan |

99% Alumina Ceramic Tube Cylinder

99% alumina ceramic tube cylinder for a pump is typically used in high-temperature and high-pressure applications where durability, wear resistance, and chemical resistance are critical. Alumina ceramics (also known as aluminum oxide) are prized for their high strength, hardness, and thermal stability, making them ideal for use in pumps that handle corrosive fluids or operate in extreme environments.

Key Characteristics of 99% Alumina Ceramics:

1. **High Thermal Conductivity**: This allows the material to dissipate heat effectively, which is crucial in pump components exposed to high temperatures.

2. **High Mechanical Strength**: Alumina ceramics can withstand high pressures without deforming, making them suitable for pump components that need to maintain integrity under stress.

3. **Low Coefficient of Thermal Expansion**: This minimizes thermal stresses during rapid temperature changes, which can be common in pump operations.

4. **Resistant to Chemical Corrosion**: They resist degradation from most chemicals, ensuring long life in harsh fluid environments.

5. **Electrical Insulation**: Useful in pumps where electrical isolation is required.

Applications in Pumps:

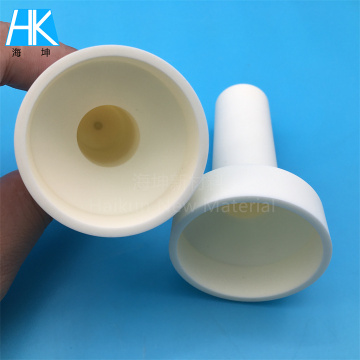

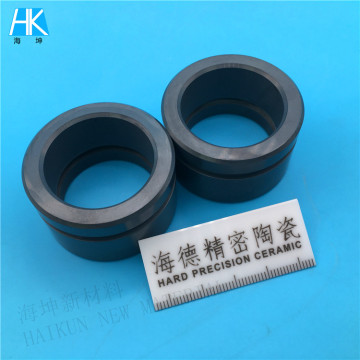

- **Pump Seals**: High-quality alumina ceramic seals can prevent leakage and ensure a long service life in pumps handling corrosive or abrasive media.

- **Pump Linings**: Linings made from 99% alumina ceramics can protect pump internals from wear caused by friction or corrosion.

- **Valves**: Valve components such as seats and inserts can benefit from alumina ceramic materials due to their wear-resistant properties.

- **Shaft Materials**: In some cases, parts of the shaft might be made from alumina ceramics to improve wear resistance or to maintain dimensional stability at high temperatures.

Manufacturing and Processing:

- **Machining**: Specialized machining tools are required to shape alumina ceramic tubes and cylinders due to their hardness.

- **Bonding and Fusing**: Sometimes, these ceramic parts are bonded or fused with other materials to enhance performance or to make them more workable.

- **Lubrication**: Due to their dry running nature, special lubrication considerations may be necessary to prevent damage during assembly or operation.

Maintenance and Repair:

- **Inspection**: Regular inspection for cracks or chips is essential, given the brittle nature of ceramics.

- **Replacement**: When damage occurs, replacement parts must match the original specifications closely to maintain optimal performance.

Conclusion:

The 99% alumina ceramic tube cylinder in a pump is a specialized component designed to withstand demanding conditions. Its properties make it an excellent choice for applications requiring exceptional durability, chemical resistance, and thermal stability. Proper selection, installation, and maintenance are crucial to ensure its longevity and reliability.

Dongguan Haikun New Material Co., Ltd which manufactures a variety of customized precision machining industrial ceramic parts' solutions since 2007.

The main advanced ceramics materials used the make the industrial ceramic parts include Zirconia Ceramic, Alumina Ceramic, Silicon Nitride Ceramic, Macor Glass Ceramci, Silicon Carbide Ceramic ,Boron Nitride Ceramic, etc.

Welcome your inquiry! +86-13823242056