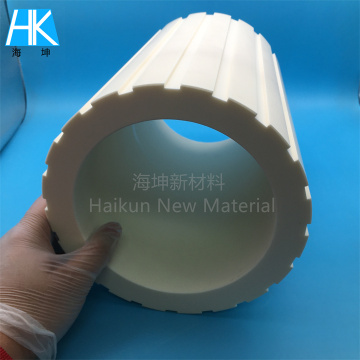

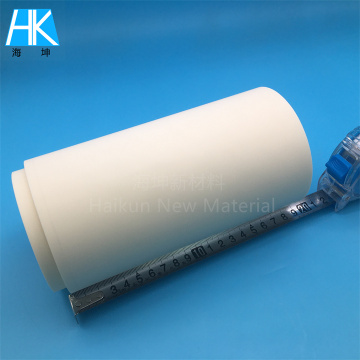

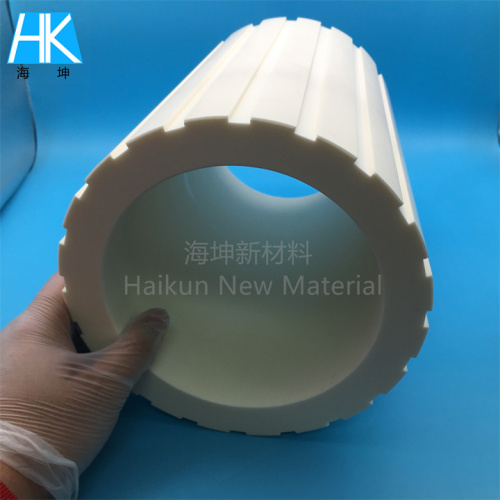

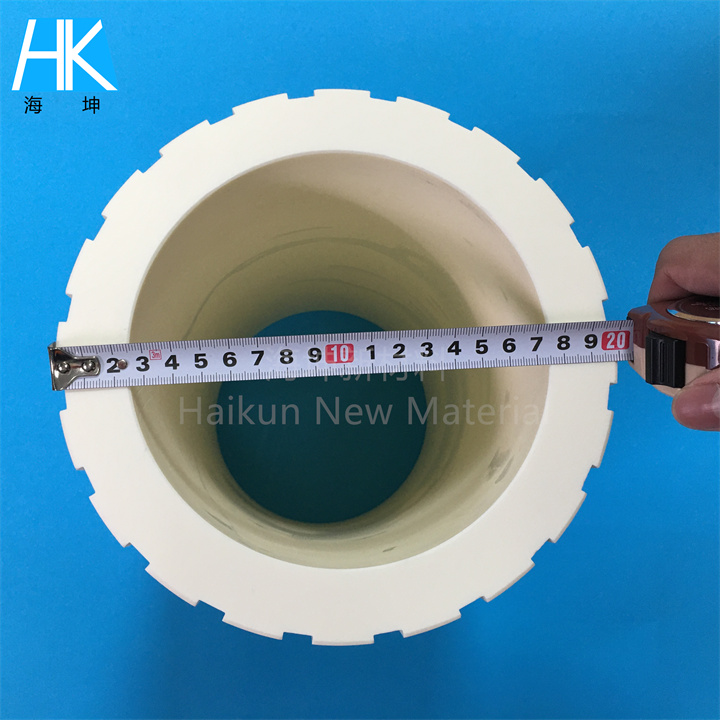

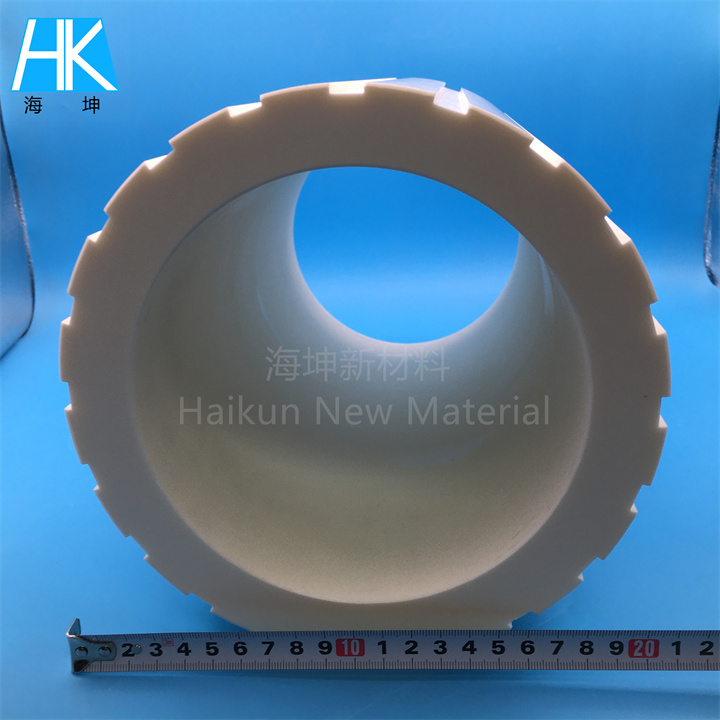

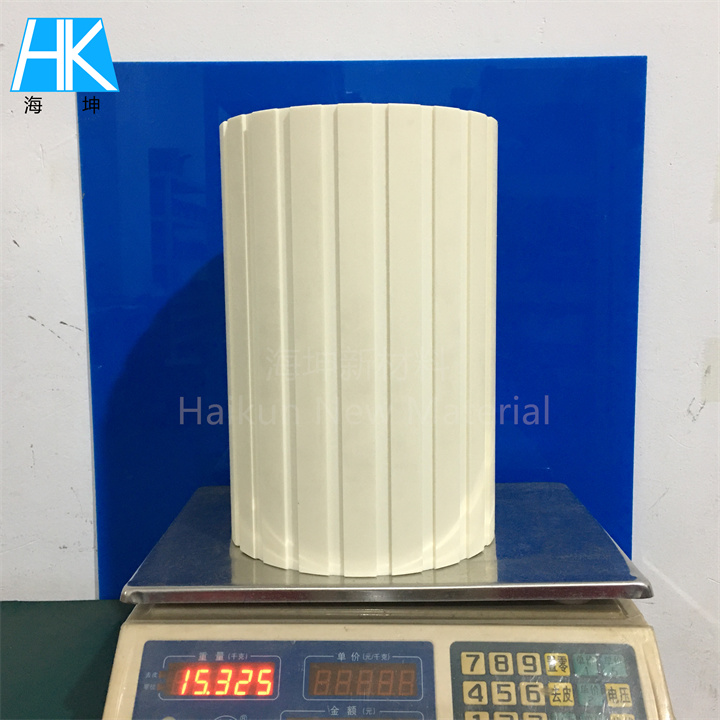

99% Alumina Ceramic Grinding Cylinder Tube

-

$3.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Dongguan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000pcs |

| Supply Ability: | 1000000pcs/month |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,Express Delivery,CIF,CFR,EXW,CPT,DDP |

| Certificate: | ISO9001 |

| HS Code: | 8547100000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Dongguan |

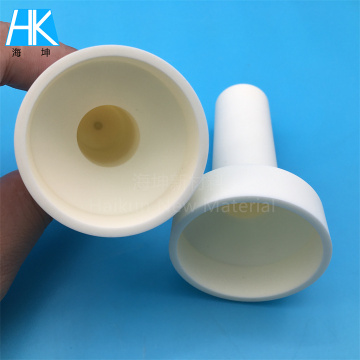

The 99% alumina ceramic grinding cylinder tube is a type of industrial component that is commonly used in various industries such as pharmaceuticals, ceramics, and semiconductor manufacturing. The term "99% alumina" refers to the percentage of aluminum oxide (Al2O3) content in the ceramic material.

Key Characteristics:

1. **High Mechanical Strength**: 99% alumina ceramics are exceptionally strong and can withstand high levels of mechanical stress, making them ideal for use in applications requiring robustness and durability.

2. **High Wear Resistance**: Due to their hardness, these materials have excellent wear resistance properties, which makes them suitable for grinding and polishing applications where they come into contact with hard or abrasive materials.

3. **Chemical Stability**: They are highly resistant to corrosion by most acids and alkalis, making them suitable for processing materials in harsh chemical environments.

4. **High Temperature Tolerance**: These ceramics can operate at high temperatures without significant degradation in performance, making them useful in processes that involve high heat, such as sintering.

5. **Electrical Insulation**: 99% alumina ceramics provide good electrical insulation, which is beneficial in electrical and electronic components where isolation from electrical interference is necessary.

Applications:

- **Pharmaceutical Industry**: Used in the milling and blending of powders to ensure uniform particle size and composition.

- **Ceramic Manufacturing**: In the production of high-quality ceramic products, where precise control over particle size and shape is crucial.

- **Semiconductor Manufacturing**: For the handling and processing of sensitive materials like silicon wafers, where precision and cleanliness are paramount.

- **Metallurgical Industry**: In the production of metals, particularly in processes that require the refinement of powders or the treatment of metal surfaces.

Manufacturing Process:

The manufacturing of 99% alumina ceramic grinding cylinder tubes typically involves the following steps:

1. **Raw Material Preparation**: High-purity alumina powder is prepared, often through calcination and purification processes to remove impurities.

2. **Mixing and Molding**: The alumina powder is mixed with a binder (like a ceramic slip or resin) and shaped into the desired form using molds or extrusion techniques.

3. **Sintering**: The molded parts undergo a high-temperature process (sintering) to fuse the particles together, forming a solid ceramic body. This step is critical for achieving the desired strength and properties.

4. **Post-Processing**: After sintering, the parts may undergo further processing such as machining to achieve the final dimensions and surface finish required.

Conclusion:

99% alumina ceramic grinding cylinder tubes are versatile components due to their combination of high mechanical strength, wear resistance, chemical stability, and temperature tolerance. Their applications span across multiple industries, demonstrating their utility in processes that require precision, durability, and reliability.

Dongguan Haikun New Material Co., Ltd which manufactures a variety of customized precision machining industrial ceramic parts' solutions more than 17 years.

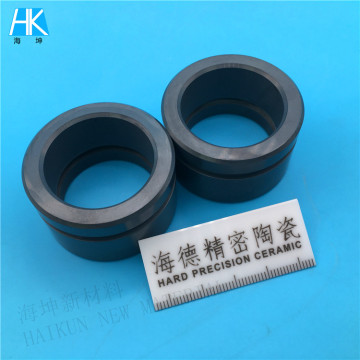

The main advanced ceramics materials used the make the industrial ceramic parts include Zirconia, Alumina, Silicon Nitride, Macor, Silicon Carbide,Boron Nitride, etc.

Our customized ceramic parts are widely used in machinery, semi-conductors,aerospace, aviation, military, nuclear power, textile, chemical, electronic, food, medical, petroleum,etc.

Welcome your inquiry! What’sapp/Wechat: +86-13823242056

Related Keywords