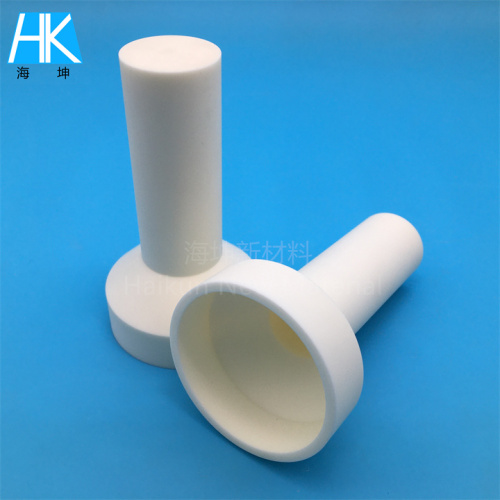

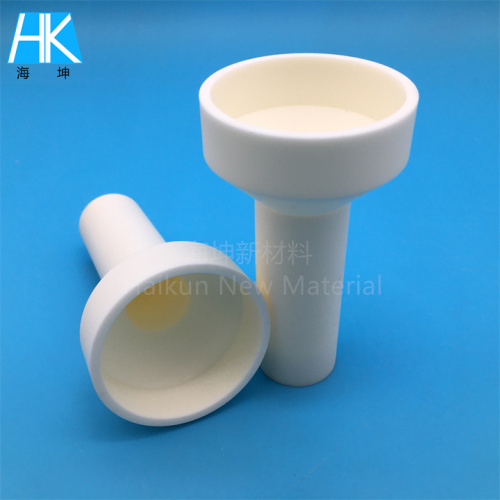

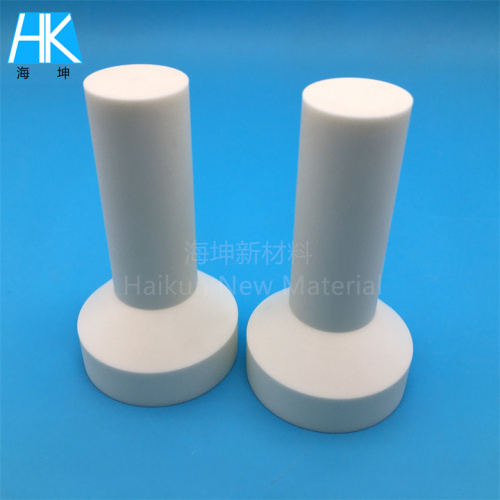

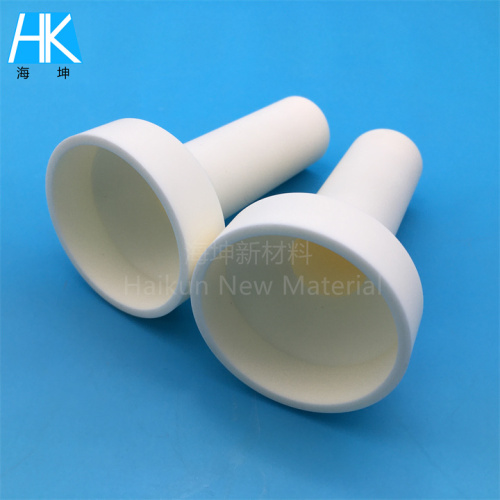

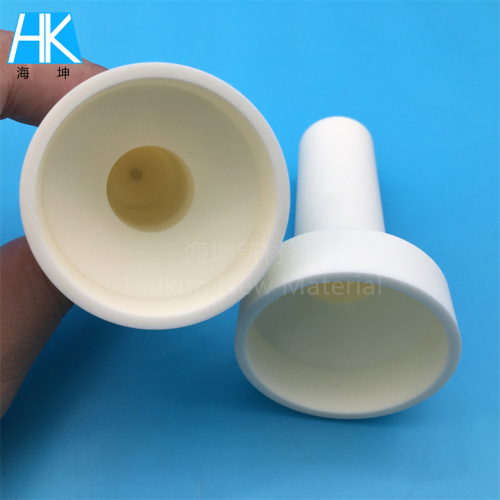

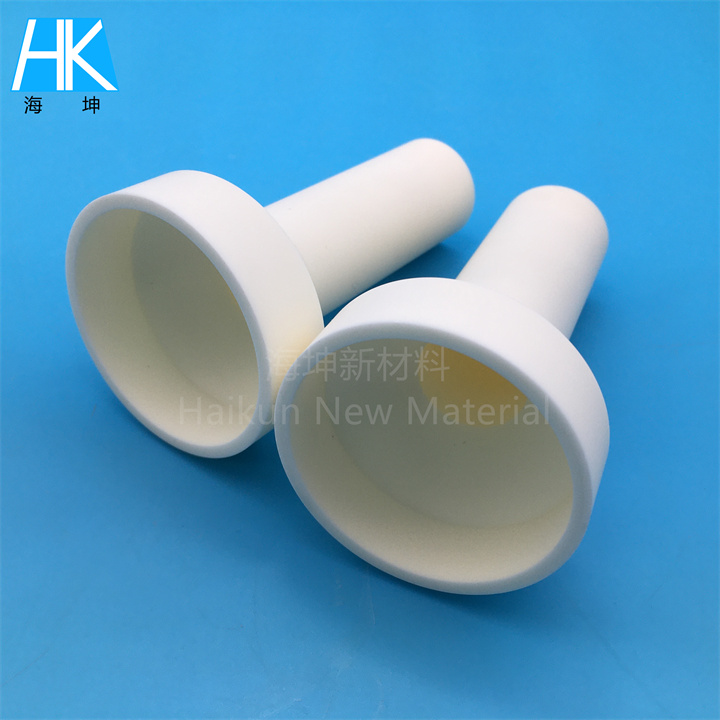

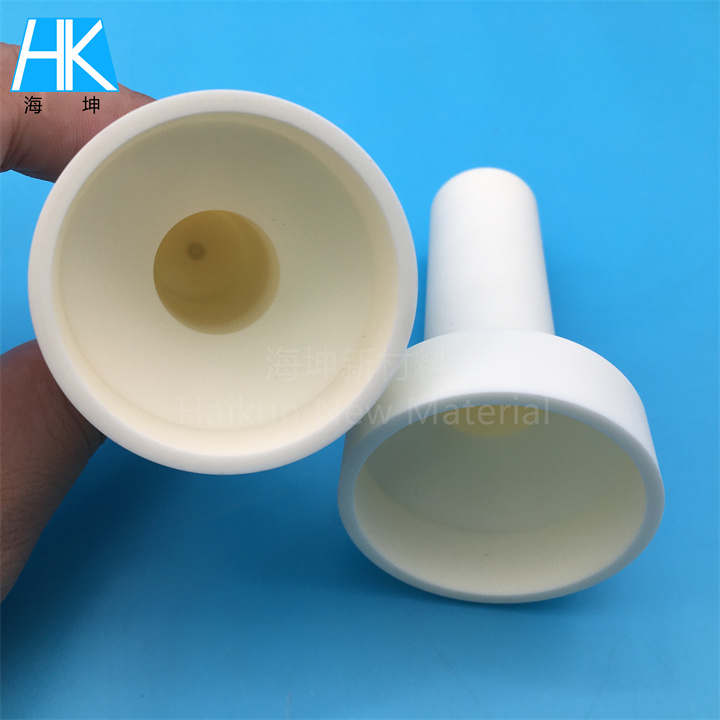

High Purity 99 Alumina Ceramic Crucible Tube with one end closed

-

$2.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Guangzhou, Shenzhen, Dongguan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000pcs/month |

| Supply Ability: | 1000000pcs/month |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,DDU,CFR,Express Delivery,CIF,EXW,CPT,DDP |

| Certificate: | ISO9001 |

| HS Code: | 8547100000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Guangzhou,Shenzhen,Dongguan |

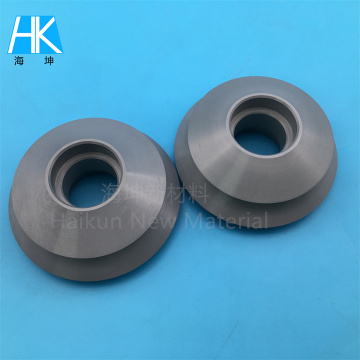

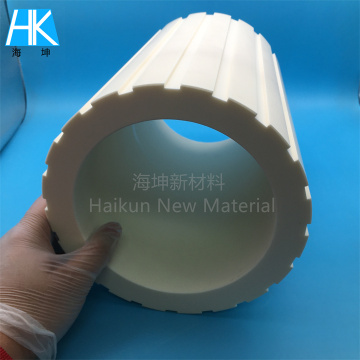

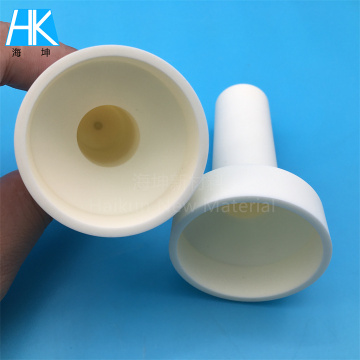

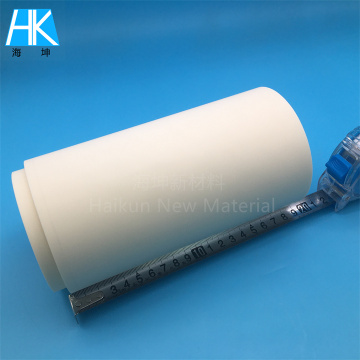

High Purity 99 Alumina Ceramic Crucible Tube with one end closed

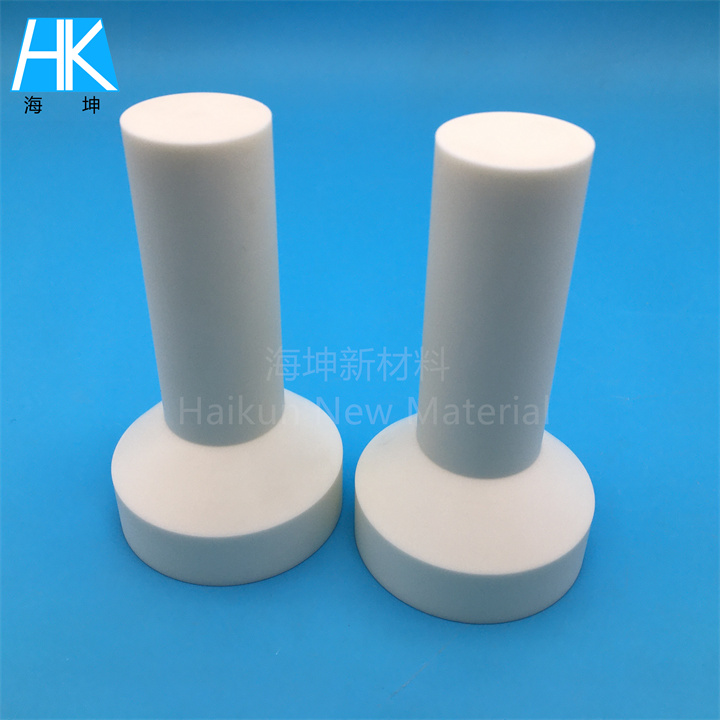

Alumina ceramic tubes are highly engineered and precision-manufactured components made from aluminum oxide (Al2O3), which is one of the most widely used ceramic materials due to its high thermal stability, electrical insulation properties, and mechanical strength. These tubes find applications in various industries because of their ability to withstand high temperatures, corrosive environments, and mechanical stresses.

Here are some key features and applications of Alumina Ceramic Tubes:

### Key Features:

1. **High Thermal Stability**: Alumina ceramics can withstand temperatures up to 1600°C without significant degradation.

2. **High Electrical Insulation**: They provide excellent resistance to electrical currents, making them suitable for use in high-voltage applications.

3. **Mechanical Strength**: They have high compressive and tensile strength, making them durable under mechanical loads.

4. **Corrosion Resistance**: Alumina is resistant to many chemical substances, enhancing their longevity in corrosive environments.

5. **Dimensional Accuracy**: Precision manufacturing ensures that these tubes meet tight tolerances, critical for specific applications.

Applications:

- **Electronics Industry**: Used in high-power electronic components, semiconductor devices, and as insulators in electrical equipment.

- **Automotive Industry**: In exhaust systems, catalytic converters, and heat exchangers where they handle high temperatures and mechanical stresses.

- **Chemical Processing**: For parts requiring resistance to chemicals and high temperatures, such as pumps, valves, and reactor linings.

- **Energy Sector**: In power plants, particularly for components that need to withstand high temperatures and pressures.

- **Medical Devices**: In implants, surgical tools, and components that require biocompatibility and resistance to sterilization processes.

- **Aerospace Industry**: Due to their lightweight and high-strength-to-weight ratio, they are used in components that need to be both strong and light.

Manufacturing Process:

Alumina ceramic tubes are typically produced through processes like powder injection molding (PIM), slip casting, or extrusion, followed by sintering to densify the material. The final product can be further processed for surface treatments or coatings to enhance specific properties.

Conclusion:

Alumina ceramic tubes are versatile components that offer a combination of high-performance characteristics, making them indispensable in numerous industries where durability, thermal stability, and chemical resistance are crucial. Their precise engineering and wide range of applications underscore their importance in modern technology and manufacturing.

Dongguan Haikun New Material Co., Ltd which manufactures a variety of customized precision machining industrial ceramic parts' solutions more than 17 years.

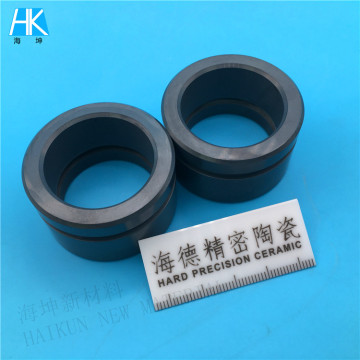

The main advanced ceramics materials used the make the industrial ceramic parts include Zirconia, Alumina, Silicon Nitride, Macor, Silicon Carbide,Boron Nitride, etc.

Our customized ceramic parts are widely used in machinery, semi-conductors,aerospace, aviation, military, nuclear power, textile, chemical, electronic, food, medical, petroleum,etc.

Welcome your inquiry! What’sapp/Wechat: +86-13823242056

Related Keywords