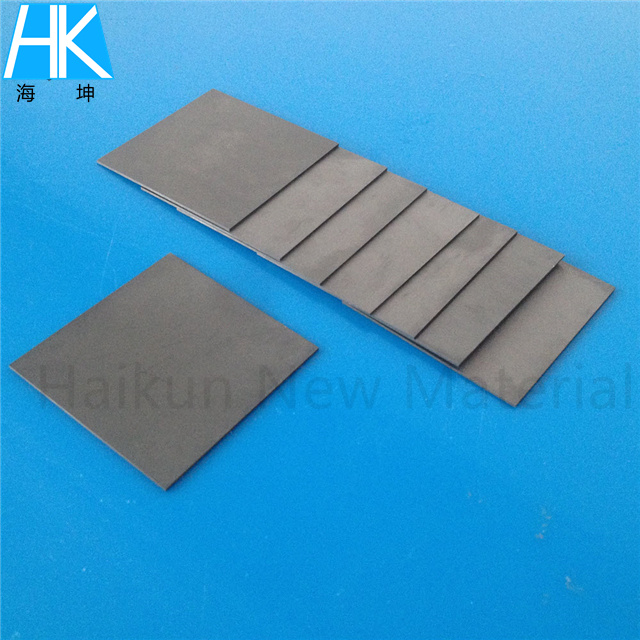

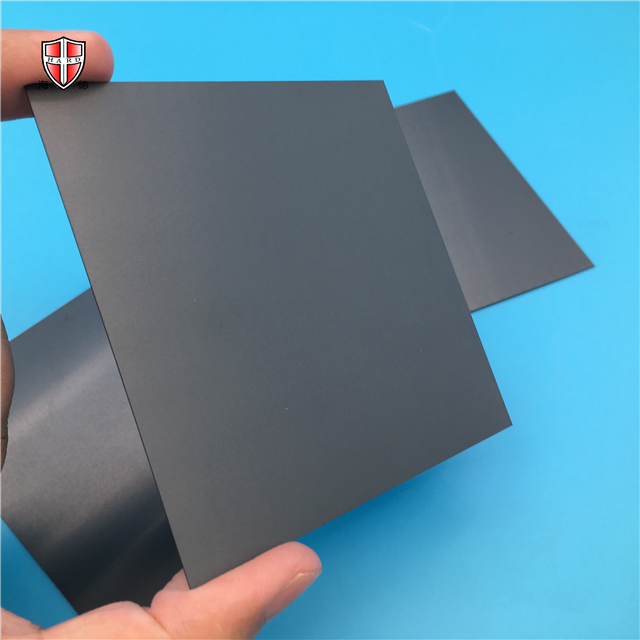

Good Thermal Shock Conductivity Si3n4 ceramic Substrate Plate

-

$0.80≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangdong, Dongguan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000pcs/month |

| Supply Ability: | 1000000pcs/month |

| Payment Type: | T/T,Paypal,Alipay |

| Incoterm: | FOB,DDU,CFR,EXW,CPT,Express Delivery |

| Certificate: | ISO9001 |

| HS Code: | 8547100000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangdong,Dongguan |

Si3N4 ceramic is an important structural material. It is a kind of super-hard material. It is lubricious and wear-resistant. It does not react with other inorganic acids except hydrofluoric acid. It has strong corrosion resistance and resistance at high temperature. Oxidation. Moreover, it can withstand cold and hot shock. It is heated to above 1,000 °C in air, and is rapidly cooled and heated rapidly without cracking. It is because of the excellent characteristics of Si3N4 ceramics that people often use it to manufacture bearings. Mechanical components such as gas turbine blades, mechanical seal rings, permanent molds, etc. If the silicon nitride ceramics with high temperature resistance and heat transfer resistance are not used to manufacture the heating surface of the engine components, the quality of the diesel engine can be improved, the fuel can be saved, and the thermal silicon nitride ceramic thermal conductivity.

Silicon Nitride Ceramic Thermal Conductivity

Silicon nitride usually offers comparatively low thermal conductivity compared to silicon carbide or aluminium nitride owing to its unique chemical composition and crystal structure. These fine ceramic grains typically grow faster in a lengthwise plane, resulting in an interlocking needle-like structure that exhibits anisotropic thermal properties. This represents significantly reduced thermal conductivity in severe temperatures. The thermal properties of silicon nitride are also unique due to the material’s high density composition, which displays a reduced magnitude of change at elevated temperatures.

Silicon Nitride Ceramic Properties:

High hardness, high strength, wear resistance, corrosion resistance, high temperature(1200°), good thermal diffusivity, good thermal shock resistance(avoid the temperature changing rapidly), good insulativity, low density. The comprehensive properties are best in most of structure ceramic.

Silicon Nitride Ceramics Applications Industries:

Machinery, electronic, semiconductor, chemical, petroleum, smelt.

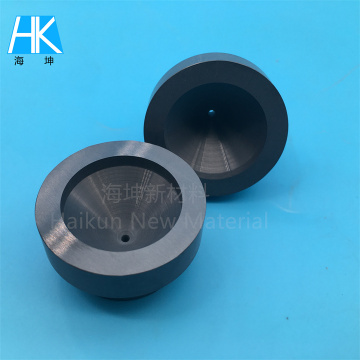

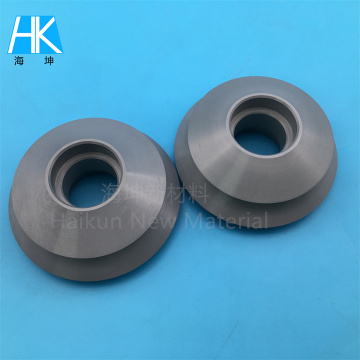

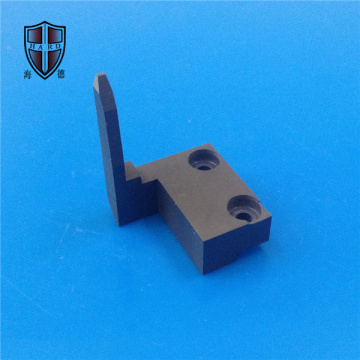

Specific application: Welding shaft, electronic substrate, plunger, nozzle, slide guide, diesel parts, metal molding, shaft wheels etc.

Dongguan Haikun New Material Co., Ltd which manufactures a variety of customized precision machining industrial ceramic parts' solutions more than 17 years.

The main advanced ceramics materials used the make the industrial ceramic parts include Zirconia, Alumina, Silicon Nitride, Macor, Silicon Carbide,Boron Nitride, etc.

Our customized ceramic parts are widely used in machinery, semi-conductors,aerospace, aviation, military, nuclear power, textile, chemical, electronic, food, medical, petroleum,etc.

If you are looking for the manufacturer or factory who can produce the Silicon Nitride Ceramic Substrate Plate or other customized ceramic parts according customer's request, pls feel free to contact with us!

Welcome your inquiry! What’sapp/Wechat: +86-13823242056