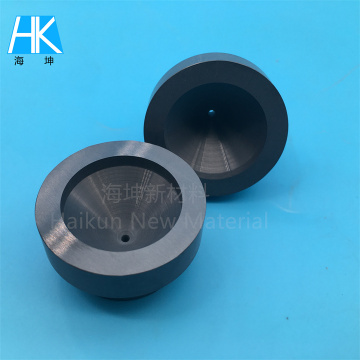

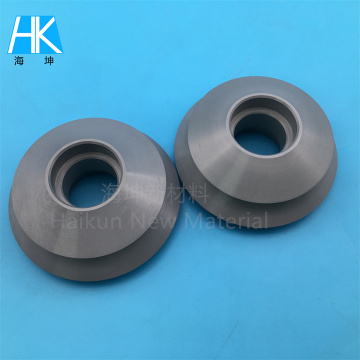

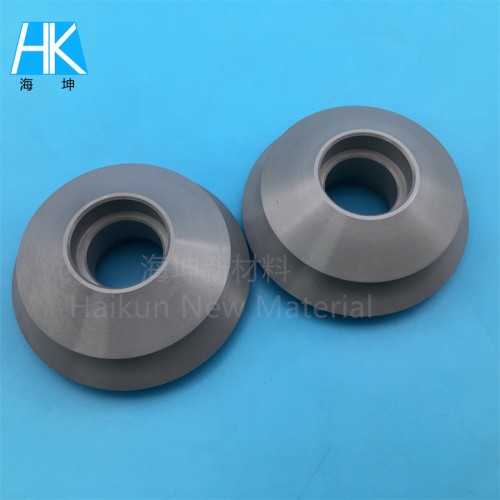

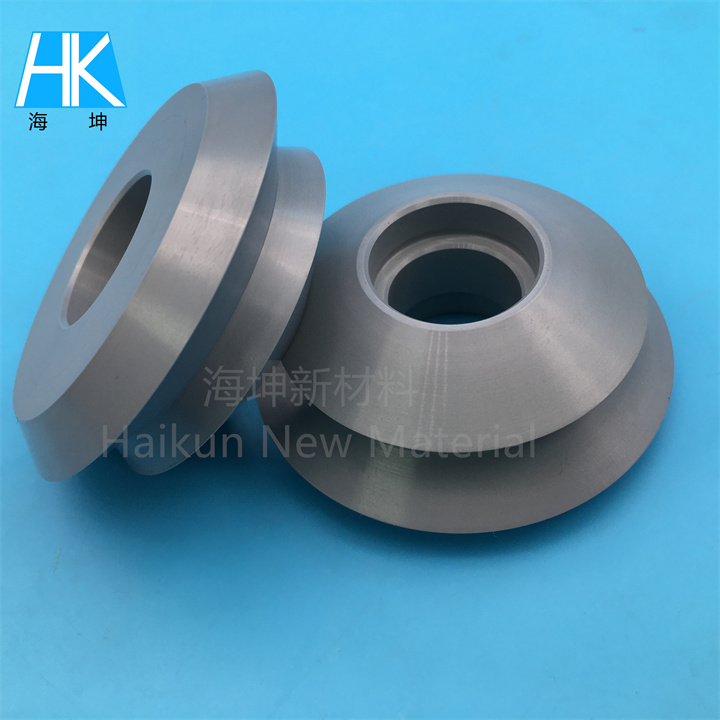

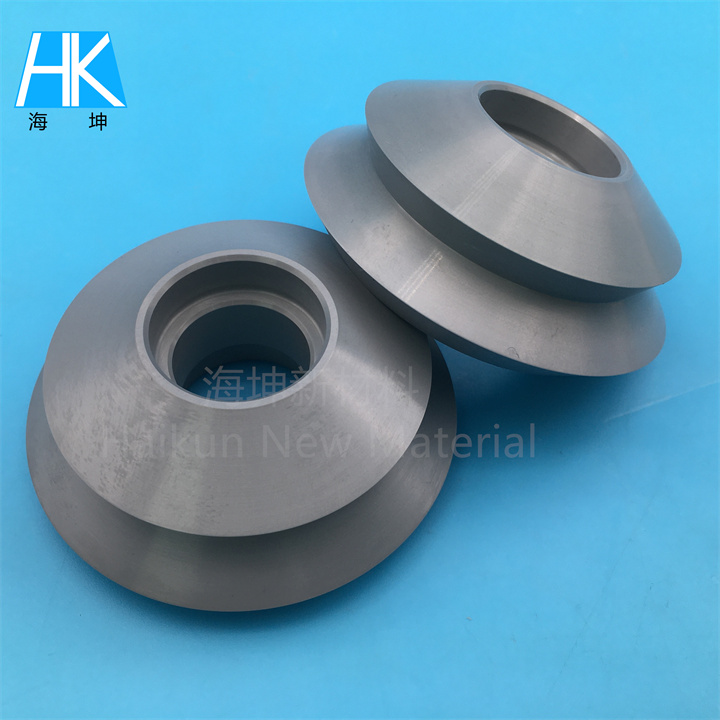

China Insulating Silicon Nitride Si3n4 Ceramic Welding Roller

-

$0.50≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangdong, Dongguan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000pcs/month |

| Supply Ability: | 1000000pcs/month |

| Payment Type: | T/T,Paypal,Alipay |

| Incoterm: | FOB,CFR,CIF,EXW,CPT,DDP,Express Delivery |

| Certificate: | ISO9001 |

| HS Code: | 8547100000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangdong,Dongguan |

Silicon Nitride (Si₃N₄) is a high-performance ceramic material known for its excellent mechanical properties, such as high hardness, fracture toughness, and wear resistance. It is often used in applications that require durability and heat resistance, such as in cutting tools, bearings, and engine components.

When it comes to "Welding Rollers," these are typically components used in the steel rolling process, where they help guide or support the metal being worked on during the welding or rolling operations. These rollers need to be highly durable and resistant to wear and heat, making silicon nitride ceramics a suitable material for them due to their superior mechanical properties.

However, welding processes typically involve high temperatures and the use of filler metals or lasers, which can be challenging when working with ceramics like silicon nitride. Traditional welding methods may not be directly applicable to ceramics. Instead, joining or repairing ceramic parts often involves specialized techniques such as:

1. **Adhesive Bonding:** Using high-temperature adhesives.

2. **Thermal Spray:** Applying a coating to repair or join surfaces.

3. **Cold Isostatic Pressing (CIP):** A technique for forming near-net-shape parts from powder materials.

4. **Laser Welding:** Although less common for ceramics, advancements in laser technology have opened up possibilities for precise joining of ceramic components under controlled conditions.

For silicon nitride ceramic welding rollers, it's more likely that the focus would be on ensuring the integrity and longevity of the component rather than traditional welding. This might include careful design to minimize stress concentrations, using advanced manufacturing techniques to ensure high-quality parts, and possibly incorporating other materials or coatings to enhance specific performance characteristics.

If you're looking into manufacturing or repairing silicon nitride ceramic welding rollers, it's important to consult with experts in ceramic engineering and materials science to ensure the best approach based on your specific requirements and operational conditions.

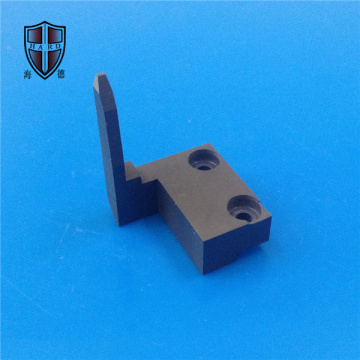

Dongguan Haikun New Material Co.,Ltd which has been producing a wide range of precision machined industrial ceramic parts and providing ceramic technology solutions since 2007.

The main advanced ceramic materials include Zirconia, Alumina, Silicon Nitride, Macor glass, Silicon Carbide,Aluminum Nitride and Boron Nitride, etc.

Product range include kinds of ceramic rods, tubes, plates,sheet,substrates, blocks, rings,washers,shafts, gears, etc and other precision machinable structural parts.

If you have the request of the Silicon Nitride Ceramic Welding Roller or other custom silicon nitride ceramic parts, pls feel free to contact with us!

What'sapp:+86-13823242056