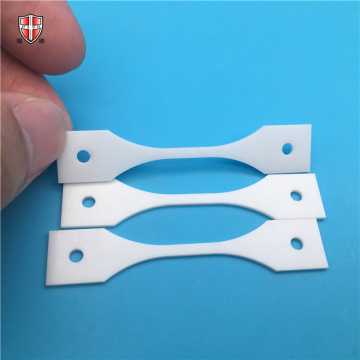

custom envelope box package little ceramic blade cutter

-

$5.001-99 Piece/Pieces

-

$3.00100-999 Piece/Pieces

-

$1.001000-9999 Piece/Pieces

-

$0.50≥10000 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Productivity: | 100,000pcs/month |

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,D/A |

| Incoterm: | FOB |

| Certificate: | SGS |

| HS Code: | 6914900000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen |

custom envelope box package little ceramic blade cutter

Reputation depends on quality, quality comes from Hard!

Zirocnia Ceramics:

How to maintain the healthy, stable and sustainable development of the zirconia industry requires the joint efforts of enterprises in the industry, especially the spirit of research and development of excellence, to further improve the production process, reduce costs, truly solve the practical difficulties of customers, strictly control quality, and provide The most reliable product. Zirconia ceramic standards are made from high-quality materials and precision engineering and offer sufficient wear resistance, making them ideal for applications where durability and reliability are important. Whether enhancing the performance of grinding wheel workpieces or optimizing machining accuracy, our zirconia ceramic parts provide superior solutions to the challenges faced by the machining industry.

The grinder and the grinding wheel motor used in standard mechanical processing all operate according to the traditional starting circuit. After the motor is started, it runs at the rated speed. Due to certain fluctuations in the grid voltage and continuous changes in the friction load of the grinding wheel workpiece, it will affect the motor speed error. The standard grinding wheel motor starting circuit generally has only one processing speed, which is difficult to adapt to different workpiece sizes and different processing relative lines. Speed, so that the processing precision of the processed workpiece is difficult to guarantee. Therefore, from the perspective of improving processing quality and processing efficiency, saving energy, etc., applying frequency conversion speed regulation technology to grinders can achieve satisfactory results. There are many types of products processed in the machining industry, and the size of the workpiece is different, and the processing accuracy is different. The relative requirement of the grinding wheel speed is different from the spindle linear speed. It is difficult to adjust the spindle speed to meet the workpiece processing linear speed to the ideal state.

Data Sheet↓

Color: CustomizedDensity: 6.0g/cm3

Zirconia Content: 94.4%

Gas permeability: 0

Water Absorption: 0

Crystal Size: 0.5um

Rockwell Hardness(45N): 78R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 800Mpa

Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Thermal Conductivity(20°C-400°C): 2.5W(m.K)

Thermal Expansion Coefficient: 9.6 10-6/°C

Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.