wearable zirconia ceramic glue adhesive blades cutters

-

$5.001-99 Piece/Pieces

-

$3.00100-999 Piece/Pieces

-

$1.001000-9999 Piece/Pieces

-

$0.50≥10000 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Productivity: | 100,000pcs/month |

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,D/A |

| Incoterm: | FOB |

| Certificate: | SGS |

| HS Code: | 6914900000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen |

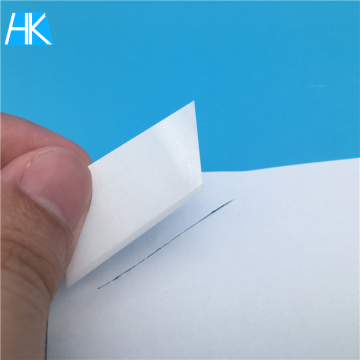

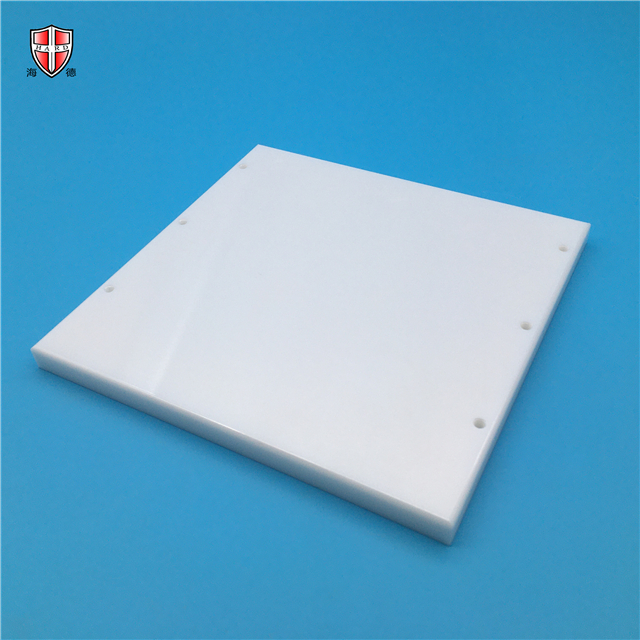

wearable Zirconia Ceramic glue adhesive blades cutters

For Zirconia Ceramic Standard Parts, it does not need to withstand high temperature environment, the strength requirements are relatively low. If the epoxy resin is expected to dry quickly and not easily loss, you can choose a resin type with a low epoxy value. If the pursuit of good permeability and high strength, epoxy resin is the ideal choice.

Working time, also known as operating time or service life, is an important stage in the curing cycle. During this period, the resin is still liquid after mixing with the curing agent, which is convenient for construction and application. In order to ensure the reliability of bonding, all construction and positioning operations must be completed successfully within the maintenance operation time.

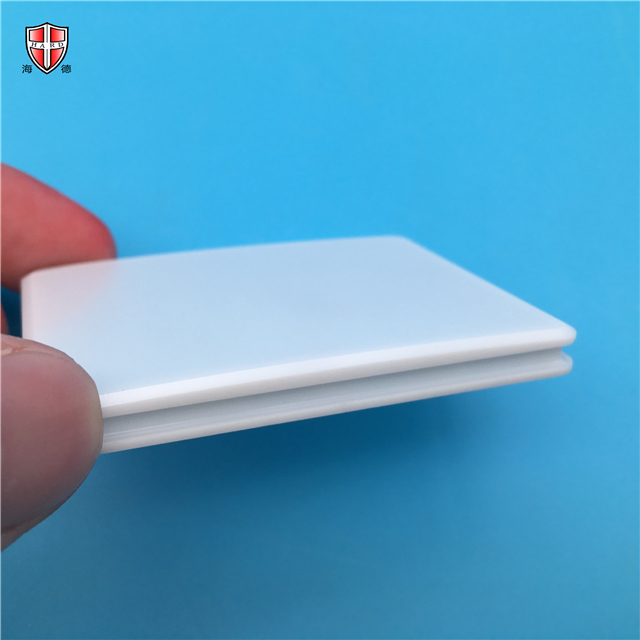

The mixture then enters the solidification stage (also known as the curing stage), where gelling or "mutation" begins. At this stage, the properties of the epoxy resin may gradually weaken, lose part of its viscosity, and should not be disturbed in any way. The mixture gradually changes to a soft, gelatinous, rubber-like texture that can be felt with a gentle press of the thumb. At this point, although the mixture is only partially cured, the newly added epoxy can still chemically connect to it, so the untreated surface still has the ability to bond or react. However, as the solidification process progresses, these abilities will gradually diminish.

When the epoxy mixture reaches the solidification stage, it can be polished and formed. At this point, the mixture has become hard enough that you can no longer press it with your thumb. At this point, the epoxy resin has about 90% of its final reaction strength, so the clamp can be removed and stored at room temperature for a few days to cure further. However, please note that at this time, the newly added epoxy resin is no longer able to chemically connect with it, so the epoxy surface must be properly pre-treated, such as grinding, to ensure good bonding mechanical strength.

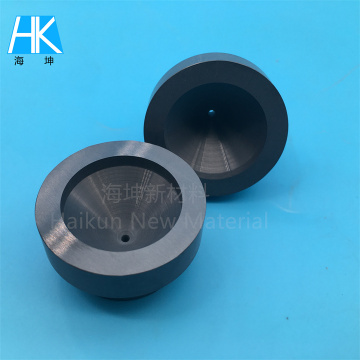

Density: 6.0g/cm3

Zirconia Content: 94.4%

Gas permeability: 0

Water Absorption: 0

Crystal Size: 0.5um

Rockwell Hardness(45N): 78R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 800Mpa

Thermal Conductivity(20°C-400°C): 2.5W(m.K)

Thermal Expansion Coefficient: 9.6 10-6/°C

Thermal Shock Resistance: 250 △T°C

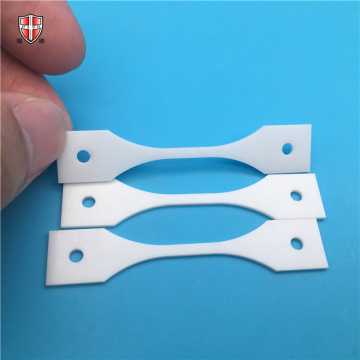

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.