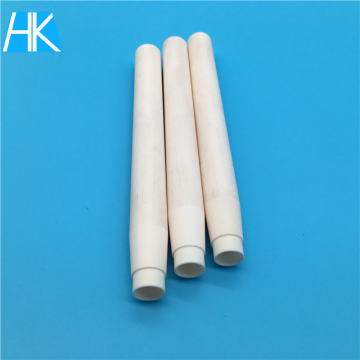

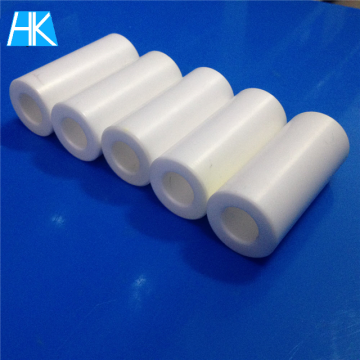

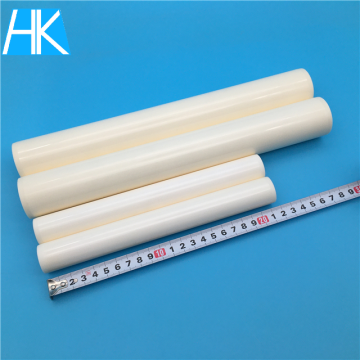

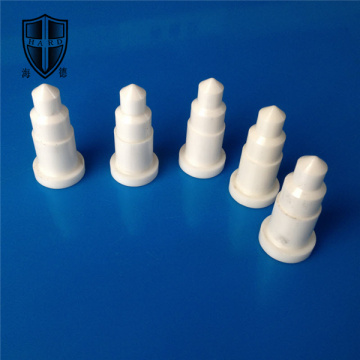

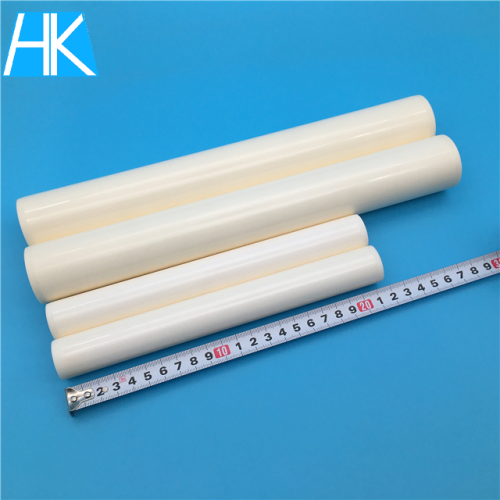

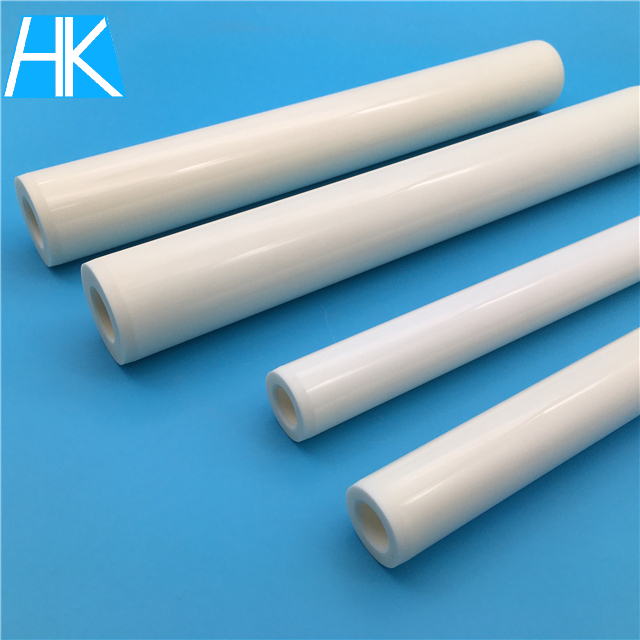

polished aluminum oxide al2o3 ceramic plunger shaft piston

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

polished aluminum oxide al2o3 ceramic plunger shaft piston

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

The performance and quality of domestically produced alumina ceramics are poor. Cannot meet market requirements. The quality and performance of Chinese polystyrene products are poor. Except for foreign investment and joint venture products, most of the products of domestic manufacturers cannot meet the performance and quality requirements of users in the electronics industry and it is difficult to enter this huge market. . In the electronics/electrical industry with the largest demand for polystyrene, imported products have an absolute advantage, and domestic resins are only used in a small amount, and they can only be used in low-end products. In order to ensure the quality of their products, well-known domestic electrical appliance manufacturers all use imported raw materials or products of foreign joint ventures. Even the expanded polystyrene used for shock-proof outer packaging usually uses imported products or products of joint ventures. The scale of the installation is small and lacks competitiveness. At present, there are nearly 40 polystyrene production plants in China, most of which have a capacity of less than 30,000 tons/year, and there are many small devices with a scale of about 10,000 tons/year. There are only 5 production plants with a capacity of 100,000 tons/year. Small devices not only have product quality that cannot be compared with advanced large-scale production devices, but also have higher production costs, which are at a disadvantage in market competition. The supply of raw materials is insufficient and the operating rate of the device is low. What is not compatible with the rapid development of polystyrene production is that the development of its raw material styrene production is relatively slow, the source of raw materials for polystyrene equipment is limited, and the operating rate is affected. In 1999, China's styrene production capacity was 846,000 tons/year, and the output was 602,000 tons. Even if all of it is used to produce polystyrene, it can only meet 43% of the domestic polystyrene production needs. Insufficient supply of raw materials is one of the main reasons for the low operating rate of the device. In 1999, China's polystyrene output was about 940,000 tons, the average operating rate of the plant was only 67%, and a large amount of production capacity was idle, which further increased China's dependence on imported polystyrene.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.