dielectric 99 alumina ceramic cylinder customized

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

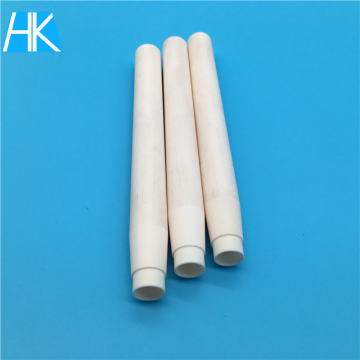

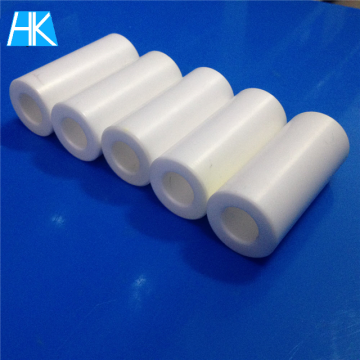

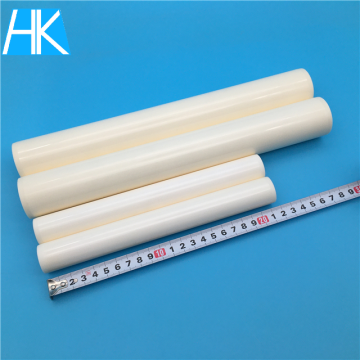

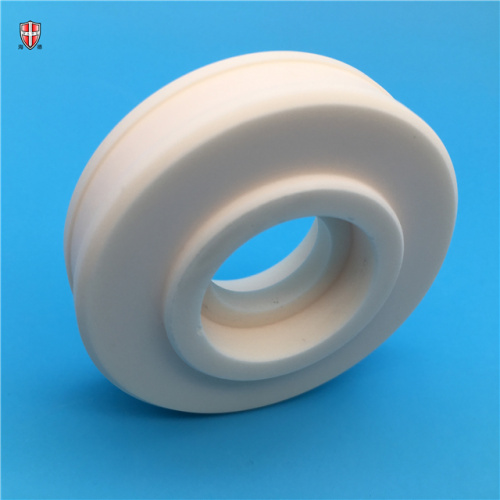

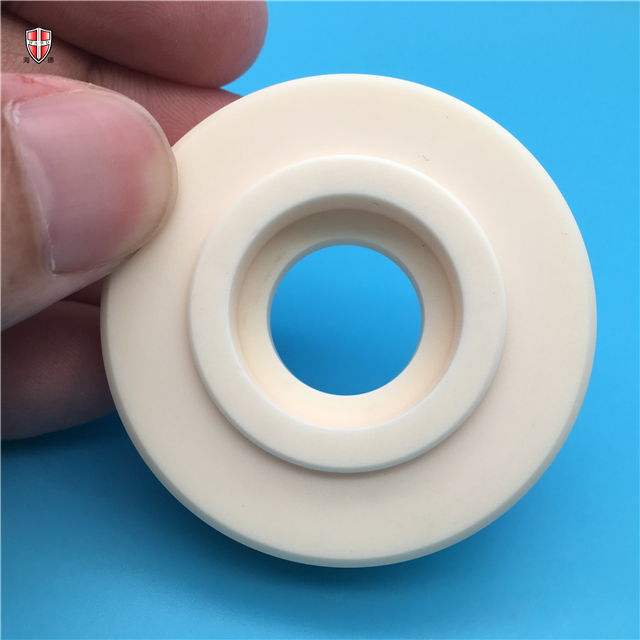

dielectric 99 alumina ceramic cylinder customized

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

The creep resistance of alumina ceramics can be increased by three orders of magnitude. If the Si3N4 ceramic material is subjected to 1400-1500 °C high-temperature pre-oxidation treatment, the Si2N2O phase is formed on the surface of the ceramic material, which can significantly improve the oxidation resistance of Si3N4 ceramics. The mechanical properties of Si3N4 ceramics produced by high-temperature strength hot-pressing sintering method are superior to those of reaction-sintered Si3N4. The strength is high, the density is high, the manufacturing cost is high, and the sintering equipment is complicated. Due to the large shrinkage of the sintered body, the dimensional accuracy of the product is limited. It is difficult to manufacture complex parts, and it is only possible to manufacture parts with simple shapes, and the machining of the workpiece is also difficult. The traditional technology process produces high content of powder impurities, high power consumption, low efficiency, and is not easy to form large-scale production. In view of this, nanotechnology experts began to find a way out from the gas phase method research, that is, through the high-temperature gas phase reaction, one step to produce ultra-fine In the gas phase method, the plasma arc gas phase synthesis technology is considered to be the current advanced technology expert. It is believed that this production line developed by Hyde has four innovations: the plasma arc three-stage compression technology is used to make the plasma beam The diameter is limited to less than 10 mm, which is conducive to energy concentration. Secondly, the designed multi-component rapid synthesizing device ensures the chemical vapor phase synthesis of the multi-ambient atmosphere in the plasma arc temperature zone. Third, the nitrogen cooling well is designed. Effectively prevent the growth of powder particles during the gradient cooling wall collection process. Fourth, the gas-solid separation technology and electrostatic collection technology are used to improve the collection rate of nano-silicon nitride powder. The nano-silicon nitride powder prepared by these techniques is used. Body, average particle size is 20 nanometers, purity is 97.5%. According to reports, nano silicon carbide and carbon can be produced on this production line. After a few months of trial production, various powders such as silicon and titanium carbonitride have achieved high efficiency of producing more than 5 kg of nano-silicon nitride powder per hour. Compared with similar products, the production cost has dropped significantly. The price has a strong competitive advantage

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

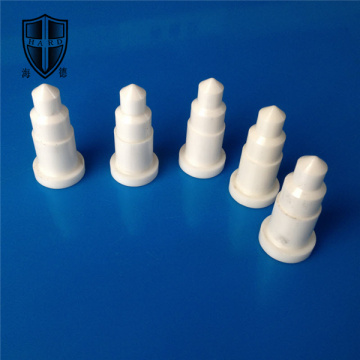

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.