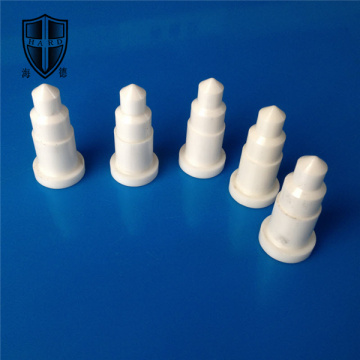

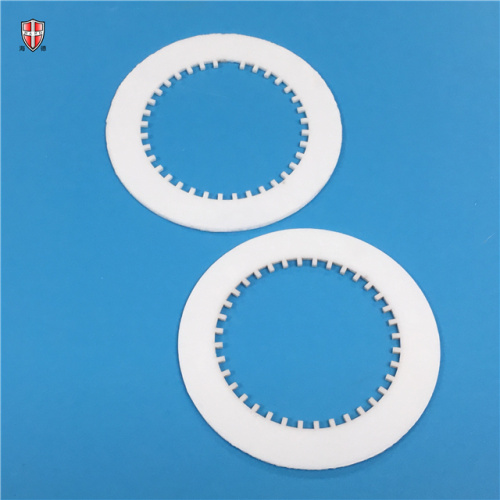

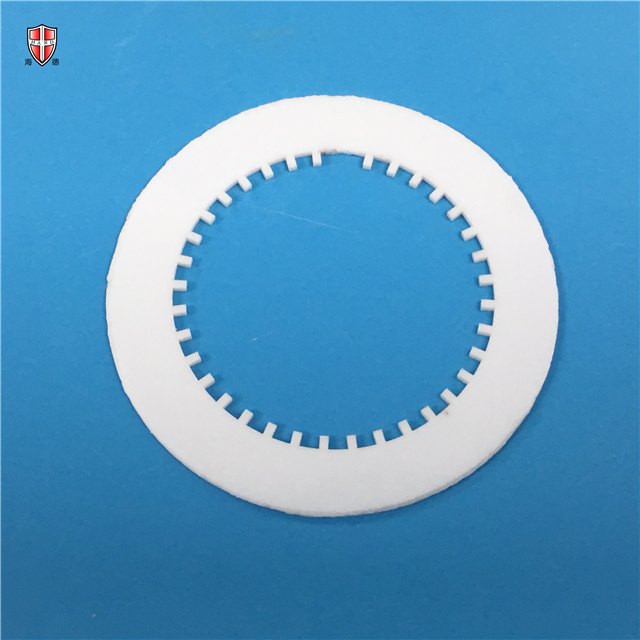

high temperature laser cutting alumina ceramic gear spacer

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

high temperature laser cutting alumina ceramic gear spacer

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

The oxide film of the anodized aluminum plate is generally above 12μ, the color is only bronze and white, and the color is monotonous. The more serious disadvantage is that the color of each aluminum veneer board is different, and many pieces of curtain wall panels are combined to form one. The overall effect of the curtain wall is very ugly. Generally it can only be used for interior decoration and is not easily accessible to people. The anodized aluminum plate is placed in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as the anode, in the specific Under the condition and the applied current, the electrolysis is performed. The aluminum plate of the anode is oxidized, and a thin layer of alumina is formed on the surface, the thickness of which is 5-20 micrometers, and the hard anodized film can reach 60-200 micrometers. In the solution, the process of forming an aluminum oxide film on the surface by electrolysis is called anodizing treatment of the aluminum plate. The cathode in the device is a material with high chemical stability in the electrolytic solution, such as lead, stainless steel, aluminum, etc. The principle of anodizing is essentially the principle of water electrolysis. When the current passes, hydrogen is evolved on the cathode; on the anode, the oxygen evolved is not only molecular oxygen, but also atomic oxygen (O) and Oxygen, molecular oxygen is usually expressed in the reaction as the aluminum is oxidized anode deposited thereon oxygen, water-free aluminum oxide film is formed, not all of the oxygen produced aluminum effect, a portion of the gaseous form of precipitates.

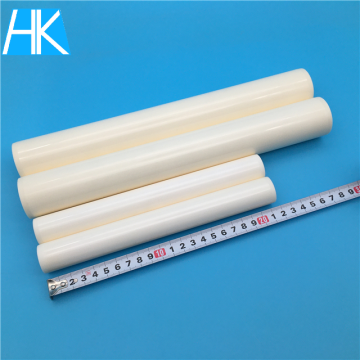

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

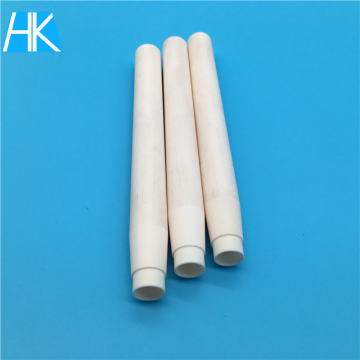

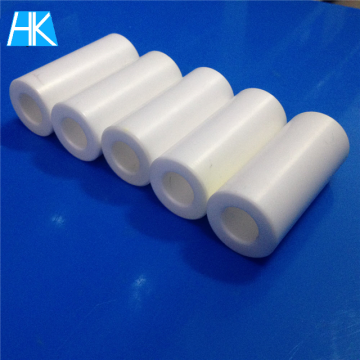

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.