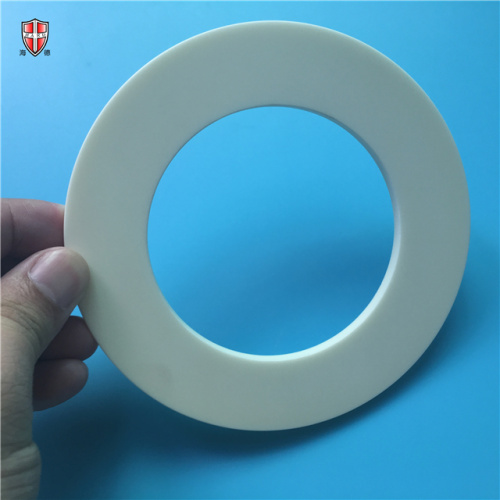

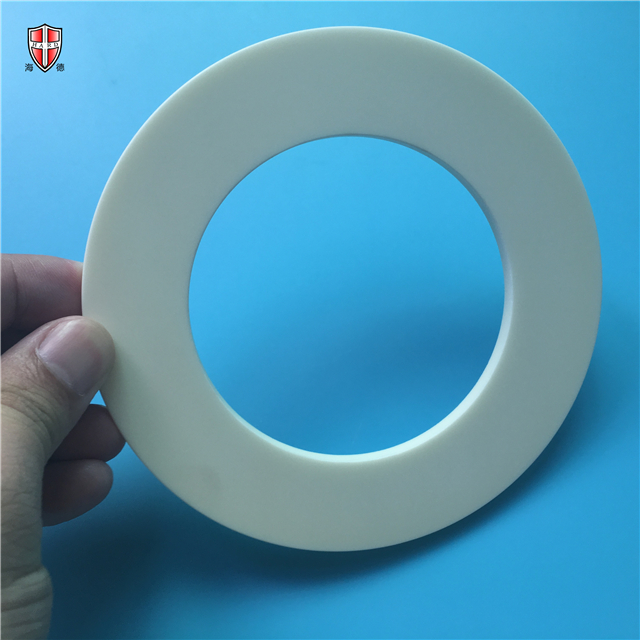

insulating corrosion resistant Alumina Ceramic Flange ring

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

insulating corrosion resistant Alumina Ceramic Flange ring

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

Alumina ceramic controlled check valves are often used in pressure holding, pressure relief, and locking circuits. Due to the pressure in the system, the oil is compressed, the pipe is expanded, the components are elastically deformed, etc., and the energy is stored. When the pressure is released, the amount of kidney is suddenly released, and when the reversing valve is from the neutral position to the left position. Because the pressure in the upper chamber of the hydraulic cylinder is large, the pressure in the lower chamber has risen at this time, and the unloading valve and the main valve are opened at almost the same time, so that the pressure oil in the upper chamber is suddenly released to the returning oil passage through the hydraulic control check valve. Because of these two reasons, the pressure-reducing small tea pressing machine is too fast, causing impact vibration and noise. For this reason, we have improved this type of hydraulic circuit.

Due to the high pressure and large flow hydraulic control check valve, the pressure relief is too fast, and the impact is increased. Therefore, a throttle valve is added to the circuit, so that the pilot valve unloading valve is opened first, then opened again. The main valve, because the throttle valve has a sufficient flow control range, can ensure a stable small flow, easy adjustment, small leakage, temperature and pressure have little effect, so by adjusting the throttle valve, control the oil in the upper chamber of the hydraulic cylinder The liquid pressure relief time is also extended accordingly, the pressure-reducing capacity is also enhanced, and the impact and noise of the hydraulic oil on each component are returned.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

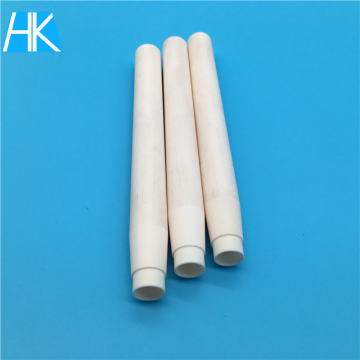

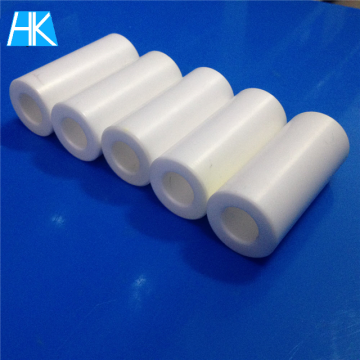

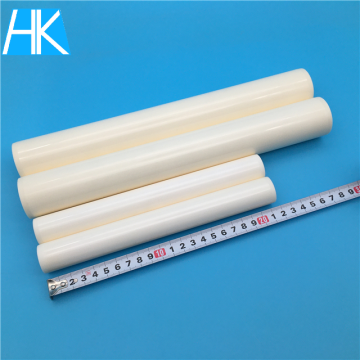

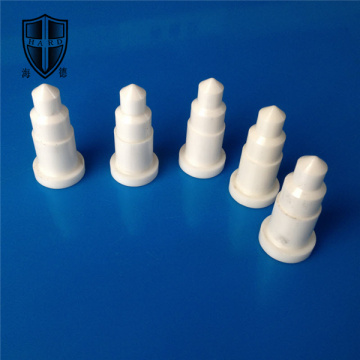

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.