presice ceramic 99% alumina cnc mechanical arm parts

-

$1.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | Paypal |

|---|

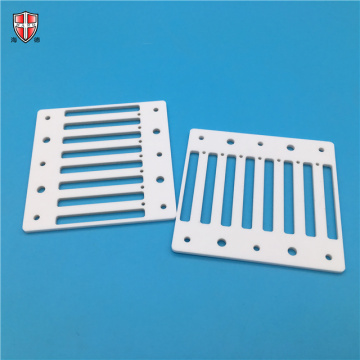

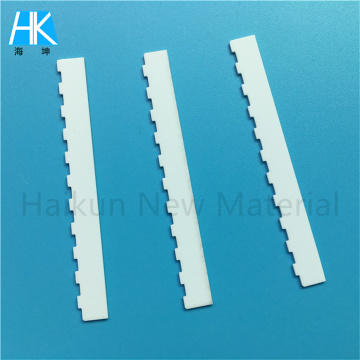

Industrial custom presice ceramic 99% alumina cnc mechanical arm parts

Reputation depends on quality, quality comes from Haikun!

Alumina Ceramic:

Alumina ceramics are ceramic materials based on alumina (Al2O3) for thick film integrated circuits. Alumina ceramics have good conductivity, mechanical strength and high temperature resistance. It should be noted that ultrasonic cleaning is required. Alumina ceramics is a versatile ceramic. Because of its superior performance, it has been widely used in modern society, satisfying the needs of daily use and special performance.

Alumina ceramic mechanical arm, also known as alumina ceramic fork, wafer transmission end actuator, is a part made of alumina ceramic, installed on the wafer handling robot, equivalent to the robot's hand, responsible for carrying the wafer silicon wafer to the designated position, its surface is directly in contact with the wafer. The alumina ceramic mechanical arm is light in weight, can effectively reduce the load of equipment and improve the service life of equipment.

Alumina ceramic mechanical arm has clamping type, bearing type, vacuum adsorption type.

After the high-purity aluminum oxide powder spray granulation, the granulating ball is dry pressed to form the embryo body and taken out from the container after cold isostatic pressing. The void between the particles in the blank body is removed by high temperature, so that the granular ceramic body is densified and formed into a solid. The surface grinding of the ceramic body is carried out with rotating grinding wheel to remove the oxide layer and impurities on the surface. Through the way of internal and external circular machining, the surface of the ceramic parts is further grinding with CNC CNC machine tools to finish the ceramic parts to ensure the accuracy and surface roughness of the ceramic parts.

Application industry: Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application: plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

Shenzhen Hard Precision Ceramic CO.,Ltd founded in 2007, located in Shenzhen of China.

We are a company that integrates development, design, molding, sintering, production and sales of precision ceramic products. After 10 years of development, we have cooperated with more than 2000 customers and 60 universities; Our factory covers an area of 2000 square meters, 50 employees, and annual production value of nearly 20 million. We have a higher visibility and better reputation in the same industry.Our products include ceramic rods, tubes, plates, blocks and precision parts for industrial. We have all-line high precision equipments from ceramic forming, sintering to precision machining. Hope for a wide range of sincere cooperation with customers at home and abroad.

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.