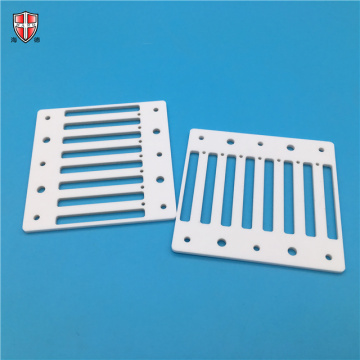

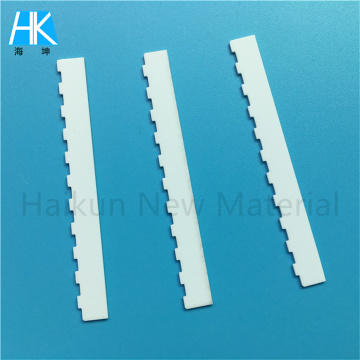

99.5% Alumina Ceramic Panel Plate for Semiconductor Equipment

-

$5.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangdong, Dongguan

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 1000000pcs/month |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,CPT,CIP,DDP,FCA |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangdong,Dongguan |

99.5% Alumina Ceramic Panel Plate for Semiconductor Equipment

99.5% alumina ceramic panel plate is a high-purity ceramic component commonly used in semiconductor manufacturing equipment due to its excellent thermal stability, wear resistance, and chemical inertness. Here are some key points about this material:

1. **High Purity**: The "99.5%" indicates that the ceramic is composed of 99.5% aluminum oxide (Al2O3), making it highly pure and minimizing impurities that could interfere with semiconductor processes.

2. **Thermal Stability**: Alumina ceramics can withstand very high temperatures without deforming or losing their mechanical properties, which is crucial in semiconductor fabrication where processes often involve high heat.

3. **Chemical Resistance**: It resists most chemicals, including acids and alkalis, which is important in cleanroom environments where contamination must be minimized.

4. **Wear Resistance**: Due to its hardness, alumina ceramics resist wear and tear, ensuring longevity in harsh conditions where parts are subject to friction or abrasion.

5. **Electrical Insulation**: Alumina ceramics have good electrical insulation properties, making them suitable for applications where electrical isolation is necessary.

6. **Dimensional Stability**: They maintain their shape and size under varying temperature conditions, which is critical for precision manufacturing processes.

7. **Applications**: These ceramic plates are often used as insulators, substrates, carrier plates, and other components in semiconductor processing equipment like sputtering systems, etching machines, and deposition tools.

When selecting a 99.5% alumina ceramic panel plate for your semiconductor equipment, consider factors such as the specific application requirements, operating temperatures, and any particular chemical exposures that may affect the material's performance.

Dongguan Haikun New Material Co., Ltd which manufactures a variety of customized precision machining industrial ceramic parts' solutions more than 17 years.

The main advanced ceramics materials used the make the industrial ceramic parts include Zirconia, Alumina, Silicon Nitride, Macor, Silicon Carbide,Boron Nitride, etc.

Our customized ceramic parts are widely used in machinery, semi-conductors,aerospace, aviation, military, nuclear power, textile, chemical, electronic, food, medical, petroleum,etc.

Welcome your inquiry! What’sapp/Wechat: +86-13823242056

Related Keywords