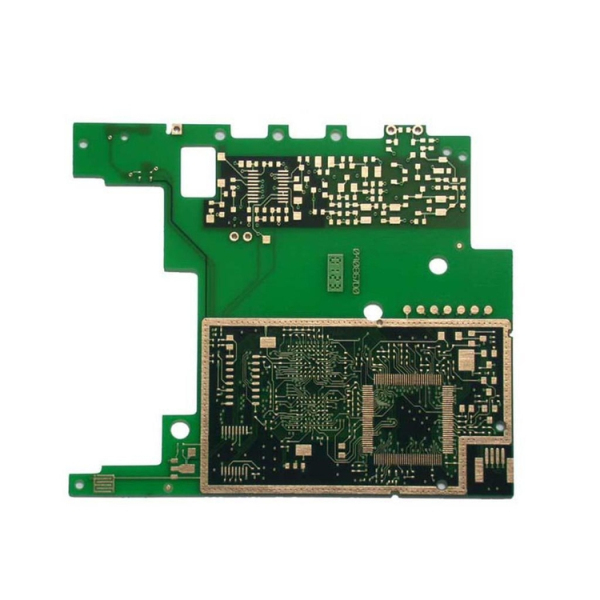

High Tg PCB Board Tg170 Fr4

-

$0.10≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

How do you waterproof a PCB board?

How to make the electronic circuit electronic components waterproof? Many times a product needs to be waterproof, and the structure "siege divisions" are busy and exhausted. In order not to delay the construction period, in order to pass the inspection, how many days and nights are struggling to be on the front line, research Various molds, full of injection molding, sealing, exhaust, various rubber pads, diversion, heat dissipation, deformation, mold opening cost, etc. How to make the product waterproof process simpler requires us to think about improvements and try boldly.

1, structure waterproof

Structural waterproofing is the most traditional mode of waterproofing electronic products, and it is also the first method that most engineers think of.

Subject: hydrophobic, diversion, effective isolation of external packaging and internal electrical parts.

Key points: Product mold design and various plugging, of course, the more complex the mold cost is not cheap. For example, in the past few years, some waterproof mobile phones used design methods such as earphone jacks and waterproof covers when charging ports, which is to start from the outside to block water to achieve the purpose of waterproofing.

Even with a lot of structural changes, it is still impossible to better prevent the infiltration of water vapor, because electronic products, especially mobile phones and earphones, are used very frequently, and users' damage to the appearance (man-made or non-man-made) is always present at any time. , The appearance also has the risk of its own deformation during use, and the gaps in the joints of the appearance will also be deformed, which becomes a potential concern.

2, potting and waterproofing

Potting method for waterproofing At present, epoxy resin potting glue is often used, which is used for the potting of electronic product modules, which can wrap the entire PCB board, so as to achieve waterproof, moisture-proof, anti-salt spray, anti-mold, anti-vibration, External force impact, etc.

Advantages: It has the characteristics of high body strength, strong adhesion, good weather resistance, low shrinkage, high insulation strength, non-toxic and environmental protection, etc., and stable mechanical and electrical properties at -45-120℃ after potting. It can protect the circuit board in all directions and greatly improve the service life of the circuit board.

Disadvantages: There are also some fatal problems. For example, the heat dissipation of the PCB board will be very affected. The most troublesome thing is that the product is almost impossible to repair, or the repair cost is too high.

3, surface coating waterproof

(1) Three-proof paint

The three-proof paint is also called circuit board protection oil, coating oil, waterproof glue, insulating paint, and moisture-proof paint. The waterproof effect of the three-proof paint products is not good, mainly due to the following shortcomings:

is generally thicker, poor heat dissipation, and high viscosity;

The coating and curing film of the three-proof paint can only protect against moisture and a small amount of water;

is not resistant to fall, vibration, and easily peeled off by external impact;

At present, many three-proof paints still use volatile solvents, which are very harmful to the human body and the environment.

But if you only need to play the most basic protective role, you can use the three-proof paint protection.

(2) PCB nano coating

Circuit board nano waterproof coating is a new nano material, also called nano coating. It is currently an ideal substitute for three-proof paint.

According to Coating Online, its thickness is only 2-4 microns, which is invisible to the naked eye. A very thin net is formed on the surface of the PCB, which effectively reduces the surface energy of the PCB and forms a lotus leaf effect. It has good heat dissipation performance and does not affect the connector. Normally conductive, waterproof can reach IPx5, basically meet the waterproof standard of life, can also be anti-corrosion, anti-acid, alkali and salt.

At present, the nano waterproof and anticorrosive materials used in electronic products on the market are roughly divided into the following three types, each with its advantages and disadvantages. Here is a brief summary of the performance of several waterproof coatings, and the majority of them will use nano waterproofing. The paint manufacturer provides a little reference.

1. Surface spray nano waterproof coating

Using the form of surface spray, a layer of nano-film is formed on the surface of the mobile phone or tablet computer, thereby preventing the entry of moisture from the outside and achieving a waterproof effect.

advantage: simple operation

Disadvantages: weak abrasion resistance. After all, the coating is on the outer shell of the product. The outer shell is the most closely contacted part of various items. In the face of too many complicated use environments, the damage rate will be greatly accelerated, and the product is in use. There is a risk of deformation of the external appearance. Once deformed, the influence of moisture on the internal circuit board cannot be guaranteed.

Coating online suggestion: can be used on some short-term waterproof products

2, coating machine vacuum spray type waterproof coating

This technology uses a vacuum coating machine to spray the water repellent into the product from the gaps in the appearance of the product in the form of a spray under vacuum conditions. The purpose is to allow the water repellent to contact the circuit parts more widely. However, because the appearance and structure of various products are different, and the sealing performance is also inconsistent, the coating formed by the water repellent inside the product is often incomplete after spraying.

Advantages: Multiple devices can operate at the same time to speed up efficiency.

Disadvantages: It is necessary to purchase a certain amount of equipment. First of all, the quality of the equipment will affect the quality of the coating. Moreover, the publicity effect of some equipment is far greater than the actual application effect, so it will be largely restricted by the performance of the equipment. According to its principle, Different mobile phones and different sealing degrees will have different reactions to the spray effect inside the product, which can easily cause incomplete coating and poor yield guarantee.

Suggestion: There must be better equipment and a good waterproofing agent.

3, PCBA immersion nano-coating

This technology is the current trend. After all the electronic components and electronic connectors on the PCB are mounted, a process is added to the production line, that is, the circuit board is directly immersed in the nano waterproof liquid, and the immersion time is only 3-5 seconds. After leaving it at room temperature for about 10 minutes, the shell can be installed, which is very convenient. There is no need to purchase equipment such as coating machine, and the conjunctiva is also very complete.

Advantages: simple operation, no need to increase equipment investment, no vacuum environment, uniform coating, only need to soak PCBA in nano waterproof liquid for a few seconds, after coating, it will not affect the conductivity of the connector, and it can resist acid Alkaline salt corrosion, because it is directly coated on the PCB board, the deformation and damage of the product appearance will not have a significant impact on the PCB. Because it is based on PCBA dip coating, it is suitable for almost all electronic products.

Disadvantages: At present, it is not possible to achieve waterproof level 7 or higher by PCB nano coating alone, which is only suitable for life waterproofing