High quality FR4 double sided PCB

-

$0.10≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express, Others

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | Paypal,T/T |

|---|---|

| Incoterm: | FOB,EXW |

| Transportation: | Ocean,Land,Air,Express,Others |

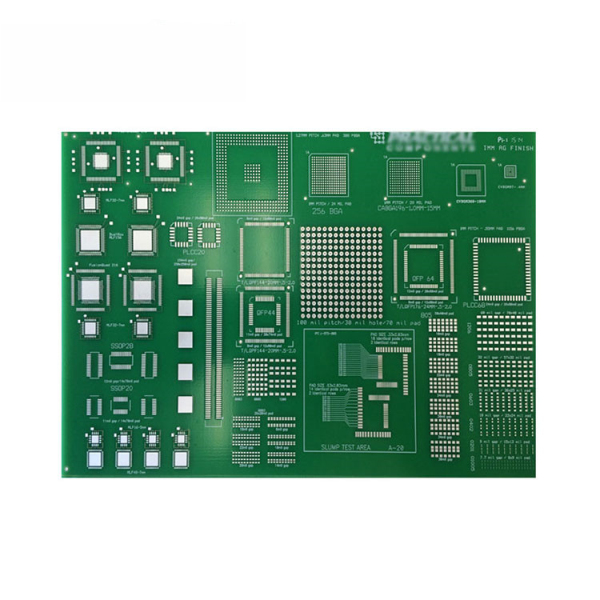

What are the 3 types of PCB?

PCB materials, layers, and manufacturing processes are diversified to suit different electronic products and their special needs, so there are many types of PCBs.

The following is a summary of some common differences, to briefly introduce the classification of PCB and its manufacturing process. Then we will analyze it from three aspects.

1. Material

2. Hard and soft finished products

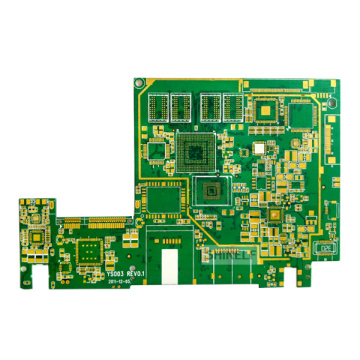

1. Rigid board: Rigid board is a kind of board made of PVC as raw material. PVC rigid board is a widely used product in the industry, especially in the chemical anti-corrosion industry.

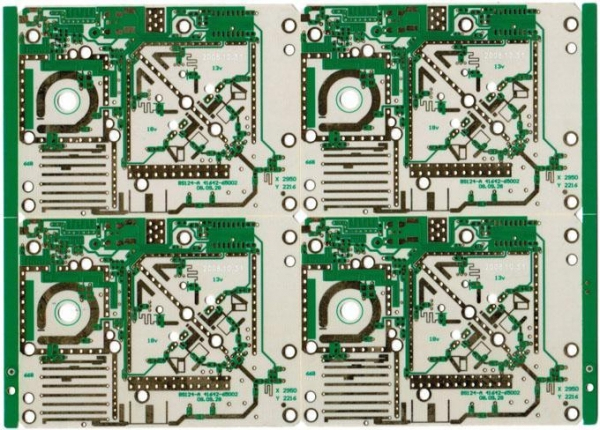

PVC is a resin resistant to acid, alkali and salt. Because of its good chemical properties and relatively low price, it is widely used in various industries such as chemical industry, building materials, light industry and machinery. As shown in the figure:

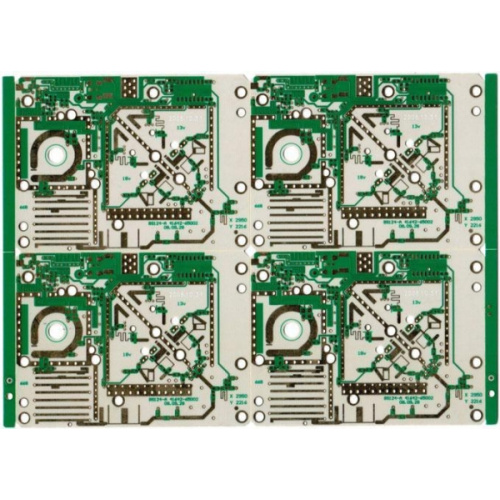

It is mainly used for the lining of anti-corrosion equipment such as acid and alkali resistance. It can also be used as general electrical insulation and sealing gasket materials. The operating temperature is -5 to +40℃. It can be used as a substitute for rubber sheets. It has a wide range of uses and is a new type of environmental protection. product. As shown in the figure:

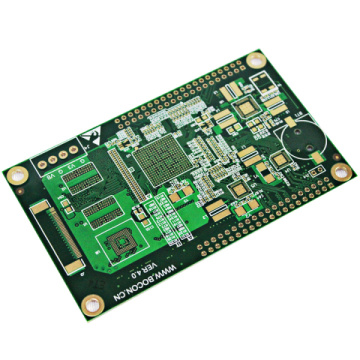

3. Rigid-Flex Board: The birth and development of FPC and PCB have given birth to a new product of rigid-flex board. Therefore, the rigid-flex board is the flexible circuit board and the rigid circuit board. After pressing and other processes, they are combined according to the relevant process requirements to form a circuit board with FPC characteristics and PCB characteristics.

Three, structure

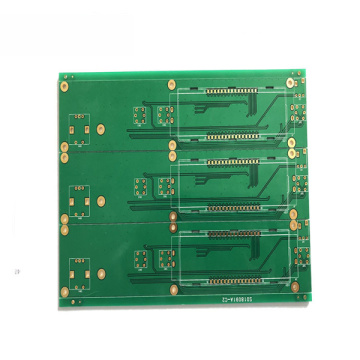

1. Single panel: Single panel is on the most basic PCB. Electronic Components are concentrated on one side, and the wires are concentrated on the other side. Because the wires only appear on one side, we call this kind of PCB a single-sided (Single-sided).

Because the single-sided board has many strict restrictions on the design of the circuit (because there is only one side, the wiring cannot cross and must be a separate path), so only early circuits use this type of board. As shown in the figure:

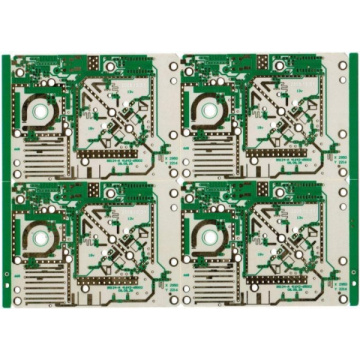

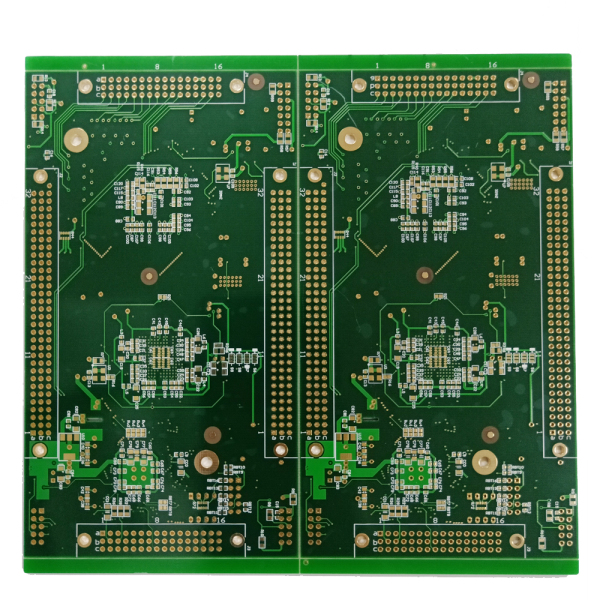

Both sides can be wired, which greatly reduces the difficulty of wiring, so it is widely used. As shown in the figure:

The above is the classification of PCBs from three aspects.

Related Keywords