Professional production of bonder

- Transportation:

- Ocean, Land

- Port:

- Shenzhen, Guangzhou, Zhuhai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | shenzhen |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land |

| Port: | Shenzhen,Guangzhou,Zhuhai |

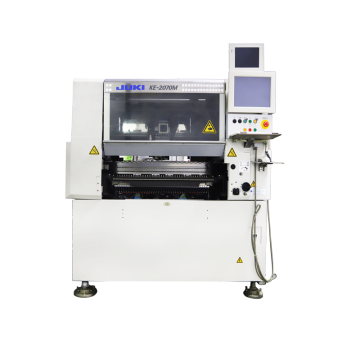

The SMD machine is a piece of equipment used for the placement of electronic components and is mainly used in the SMD production process in the electronics manufacturing industry.Smt Machine

The basic principle of a mounter is to remove electronic components from the feeder with high speed and accuracy through computer control and then precisely place them in the corresponding position on the printed circuit board (PCB). The main components of a placement machine include the feeder, placement head, drive system, image processing system and computer control system.Juki Feeder

The feeder is an important part of the placement machine and is mainly used to supply electronic components to the placement head. The head removes the components from the feeder by means of a suction cup or needle tool and then places them precisely on the PCB. The placement head is usually characterised by high speed, high precision and reliability to meet the requirements of electronic product placement.Feeder Manufacturers

The bonder is used in a wide range of applications and is used in all areas of the electronics manufacturing industry. Whether it is mobile phones, tablet PCs, televisions, or electronic games, security equipment, automotive electronics and other products, the placement process is inseparable from the placement machine. The high efficiency and quality of the placement machine can meet the needs of electronic product production and improve production efficiency and product quality.

Parameters of JUKI-KE-2070L

Alien Plug-in:

|

Feeder |

Bulk material, tray material, |

|

Number of feeders that can be loaded |

Tape feeder: 14 |

|

Material height |

Ke2050 height≤20mm Ke2060 height s25mm |

|

Material size |

KE2050: 0.6*0.3~ Line length 47MM

|

|

Number of plug-in headers |

Ke2050- .4个

|

|

Reclaiming method |

1. Draw |

|

Substrate size |

|

|

Plug-in accuracy |

+/-0.05MM

|

|

Plug-in speed

|

The fastest 0.7S/piece |

|

Equipment size |

1500*1500*1450MM

|

|

Power supply/power. |

Power supply: three-phase 380V |

|

Weight/air consumption |

Weight: 1500KG |

Company Overview

Our company integrates SMT equipment sales and maintenance.

The products cover all aspects of the SMT industry. The main business scope is placement machines, peripheral products, feeders, suction nozzles, and placement machine accessories services.

Engaged in the business of JUKI equipment and JUKI feeder for 14 years.

Strives for innovative development and dedication to provide you with assured quality products and services.

We provide customers with competitive, safe and reliable products, solutions and services in the fields of SMT patches and plug-ins.

Open cooperation with the industry's ecological partners, increase business barriers, continue to create value for customers, and insist on continuous innovation around customer needs.

Our team

We always put you first, continue to grow and innovate, and provide you with suitable solutions.

The brands we work with

We have in-depth discussions and cooperation with many brands, work down-to-earth, and win trust.

Actively expand products to SMT peripheral equipment.

Integrate the advantages of products to provide customers with a complete set of SMT equipment and production solutions, as well as a fully automated intelligent industry line.

Provide customers with a full range of solutions to achieve the goal of improving efficiency and reducing costs, so as to achieve a win-win situation for customers and the company.