Wastewater Treatment Automatic Filter Press

-

$4850.001-2 Set/Sets

-

$4680.00≥3 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- shenzhen, qingdao, shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | china |

|---|---|

| Productivity: | 5000sets/year |

| Supply Ability: | 5000sets/year |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 8421291090 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | shenzhen,qingdao,shanghai |

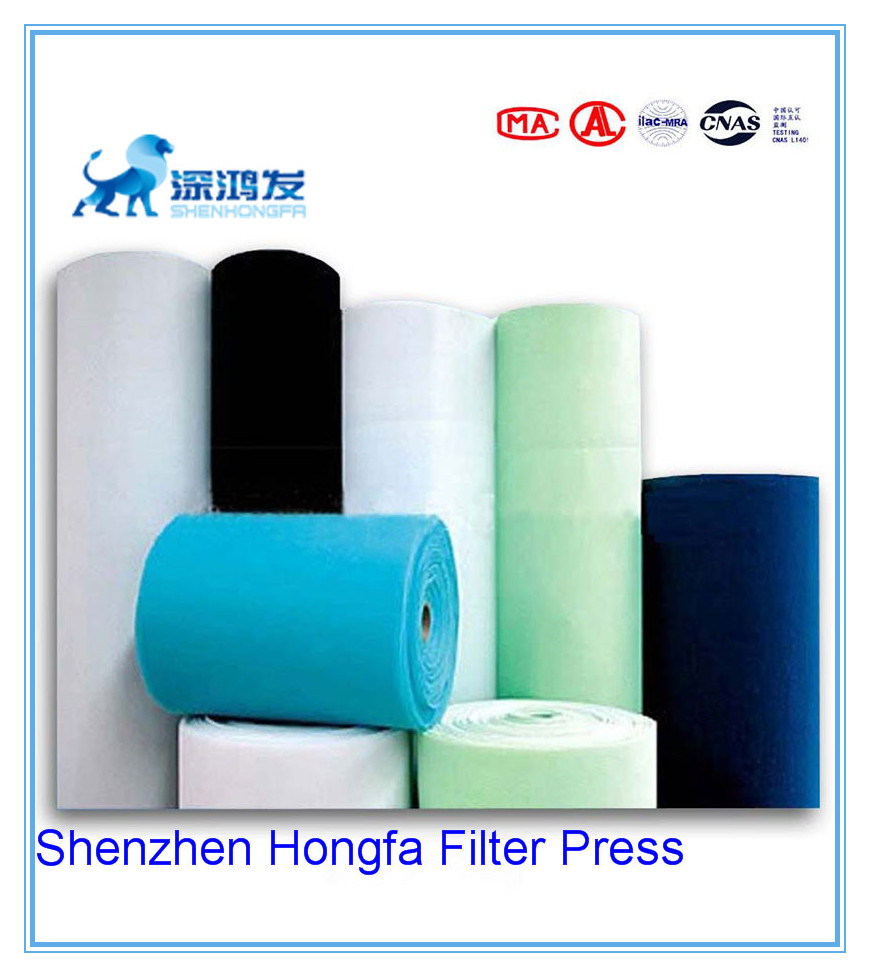

Filter cloth material

1.1.1 Polypropylene fiber filter cloth Polypropylene fiber is made of propylene as raw material by polymerization, melt spinning fiber, price is relatively low. Polypropylene fiber press cloth has good chemical corrosion resistance, good resistance to acid and alkali, high mechanical strength, wear resistance. The wet strength of polypropylene fiber is basically equal to the dry strength, and the strength of polypropylene fiber filter cloth basically remains unchanged during the filtration process after mud entry. The moisture absorption of polypropylene fiber filter cloth is very small, almost no moisture absorption, a large air strip under the moisture recovery rate is close to zero, but it has core suction, can pass through the capillary in the fabric to transfer water vapor, but does not have any absorption effect. The vertical surface of polypropylene fiber is flat, straight and light, and it is also convenient to peel off the sludge after the mud is compressed. However, polypropylene fiber filter cloth has poor light resistance, poor thermal stability and easy aging. 1.1.2 Polyester filter cloth polyester is a fiber made from refined terephthalic acid (PTA) or dimethyl terephthalate (DMT) and ethylene glycol (EG), which is a fiber forming polymer, polyethylene terephthalate (PET), which is produced by esterification or transesterification and polycondensation reaction. Polyester has high strength, good wear resistance, good light resistance, corrosion resistance, resistance to bleaching agents, oxidants, hydrocarbons, ketones, petroleum products and inorganic acids, resistance to dilute alkali, not afraid of mold, but hot alkali can make it decompose. Because polyester filter cloth is less hygroscopic, its wet strength and dry strength is basically the same. The elasticity is close to wool, and it can recover almost completely when it is extended by 5% ~ 6%. Wrinkle resistance is more than other fibers, that is, the fabric does not wrinkle, good dimensional stability.

1.1.3 Nylon filter cloth nylon fiber has high strength, the strength is 4 ~ 5.3 Cndtex, and the elongation is 18% ~ 45%. At 10% elongation, the elastic homocomplex rate is more than 90%. The strength of nylon is the strongest in the fiber, according to the test, the wear resistance of nylon fiber is 10 times that of cotton fiber and 50 times that of viscose. Wear resistance in a variety of fibers first. Polyamide fiber is resistant to strong alkali and weak acid. But nylon is light resistant, easy to change color brittle, so nylon fabric should not be exposed to the sun for a long time. The chemical name of Vylon filter cloth is polyvinyl alcohol. Its strength is lower than that of polyester, and its strength is only 3.52 ~ 5.72 Cndtex. Elongation of fracture is 12% ~ 25%. The elasticity is poor, the shape of the fabric is poor, the wear resistance is good, and the durability is 1 ~ 2 times that of pure cotton. But one of the biggest advantages is that it can withstand the use of strong alkali, and good moisture absorption, easy to combine with rubber in one, is a good material used in the rubber industry, its disadvantage is low temperature resistance, temperature up to 100 °C shrinkage, no acid resistance.