electronic PCB silicon nitride ceramic circuit board blank

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

electronic PCB silicon nitride ceramic circuit board blank

Reputation depends on quality, quality comes from Hard!

Silicon Nitride Ceramic:

The ancient lathe used hands or pedals to rotate the work piece through ropes and hold the cutting tool for cutting. In 1797, British mechanical inventor Mozley created a modern lathe that uses a screw to drive the tool post, and in 1800 it adopted an exchange gear to change the feed speed and the pitch of the processed thread. In 1817, another Englishman, Roberts, used a four-stage pulley and back-wheel mechanism to change the spindle speed. In order to improve the degree of mechanization and automation, in 1845, Fitch in the United States invented the turret lathe. In 1848, there was a back-wheel lathe in the United States. In 1873, Spencer of the United States made a single-axis automatic lathe, and soon he made a three-axis automatic lathe. At the beginning of the 20th century, a lathe with a gearbox driven by a separate motor appeared. After the First World War, various high-efficiency automatic lathes and specialized lathes developed rapidly due to the needs of munitions, automobiles and other machinery industries. In order to improve the productivity of small batches of workpieces, lathes with hydraulic profiling devices were promoted in the late 1940s. At the same time, multi-tool lathes were also developed. In the 1950s, program-controlled lathes with punched cards, latch plates and dials were developed. Numerical control technology began to be used in lathes in the 1960s and developed rapidly after the 1970s.

properties:

High hardness, high strength, wear resistance, corrosion resistance, high temperature(1200°), good thermal diffusivity, good thermal shock resistance(avoid the temperature changing rapidly), good insulativity, low density. The comprehensive properties are best in most of structure ceramic.

Data Sheet↓

Color: Black GreyDensity: >3.2g/cm3

Hardness: HRA90

Vickers Hardness (Hv50): >1550 HV0.5

Modulus of Elasticity: 290Gpa

Flexural Strength: >600Mpa

Compressive Strength: 2500Mpa

Modulus of Elasticity(25°C): 65Gpa

Fracture toughness:>6.0 Mpam1/2

Maximum Use Temperature: 1200°C

Thermal Conductivity:15-20 W(m.K)

Thermal Expansion Coefficient: >3.1 10-6/°C

Thermal Shock Resistance: 500 △T°C

Special Heat Capacity: 700 KJ/kg.K

Dielectric Strength: 1 KV/mm

Dielectric Constant: er

Volume Resistivity(20°C): 1.0*10(12)Ω.cm

Application industry:

Machinery, electronic, semiconductor, chemical, petroleum, smelt.

Specific application:

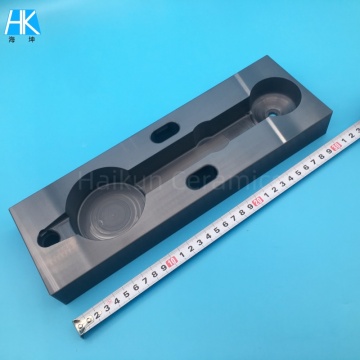

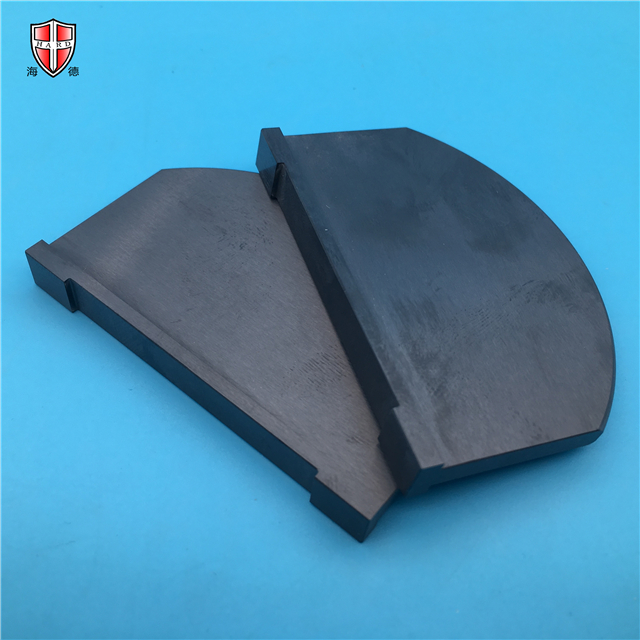

Welding shaft, electronic substrate, plunger, nozzle, slide guide, diesel parts, metal molding, shaft wheels etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

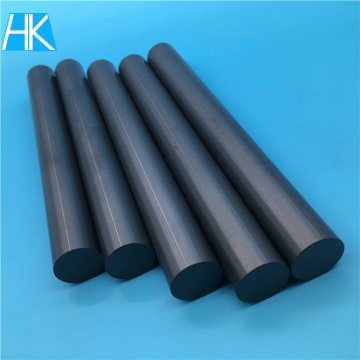

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.