PCB silicon nitride ceramic sheet substrate chip potsherd

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

PCB electronic silicon nitride ceramic sheet substrate chip potsherd

Reputation depends on quality, quality comes from Hard!

Silicon Nitride Ceramic:

After the plastic is plasticized in the heating barrel of the injection molding machine, it is injected into the cavity of a closed mold by a plunger or a reciprocating screw to form a plastic processing method. This method can process products with complex shapes, precise dimensions or with inserts, and the High Precision Ceramic Network Resistor Substrate Plate production efficiency is high. Most thermoplastics and some thermosetting plastics (such as phenolic plastics) can be processed by this method. The material used for injection molding must have good fluidity to fill the High Precision Ceramic Network Resistor Substrate Plate mold cavity to obtain the product. Since the 1970s, a kind of injection molding with chemical reactions, called reaction injection molding, has developed rapidly. The main part of the injection molding machine. The plastic is heated and plasticized into a fluid state and injected into the mold under pressure. The injection methods are plunger, pre-plasticized and reciprocating screw. The latter (Figure 1) has the advantages of uniform plasticization, small injection pressure loss, compact structure, etc., and is widely used. Varies due to processing materials. The injection molding of thermoplastics includes processes such as feeding, plasticizing, injection, holding pressure, cooling, and demoulding. Thermosetting plastics and rubber molding also include the same process, but the barrel temperature is lower than that of thermoplastics, but the injection pressure is higher. The High Precision Ceramic Network Resistor Substrate Plate mold is heated. After the material is injected, it needs to undergo a curing or vulcanization process in the mold, and then release the film while it is hot .

Injection molding refers to a model with a certain shape. The melted gel is injected into the cavity by pressure to form. The process principle is: melt the solid plastic at a certain melting point, and inject the mold at a certain speed through the pressure of the injection machine Inside, the mold is cooled by water channels to solidify the plastic to obtain the same product as the designed cavity.

properties:

High hardness, high strength, wear resistance, corrosion resistance, high temperature(1200°), good thermal diffusivity, good thermal shock resistance(avoid the temperature changing rapidly), good insulativity, low density. The comprehensive properties are best in most of structure ceramic.

Data Sheet↓

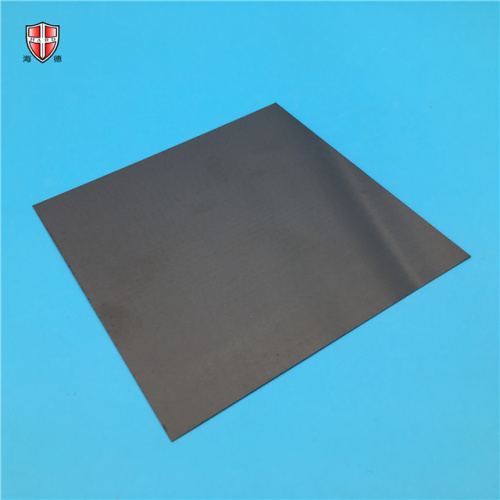

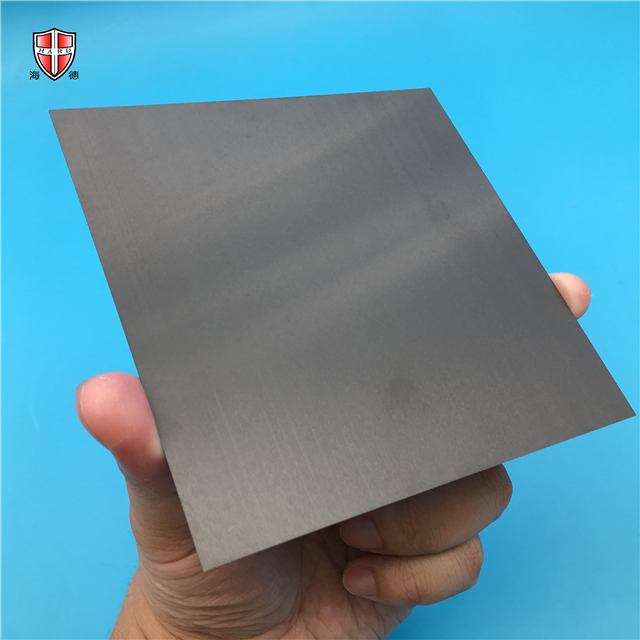

Color: Black GreyDensity: >3.2g/cm3

Hardness: HRA90

Vickers Hardness (Hv50): >1550 HV0.5

Modulus of Elasticity: 290Gpa

Flexural Strength: >600Mpa

Compressive Strength: 2500Mpa

Modulus of Elasticity(25°C): 65Gpa

Fracture toughness:>6.0 Mpam1/2

Maximum Use Temperature: 1200°C

Thermal Conductivity:15-20 W(m.K)

Thermal Expansion Coefficient: >3.1 10-6/°C

Thermal Shock Resistance: 500 △T°C

Special Heat Capacity: 700 KJ/kg.K

Dielectric Strength: 1 KV/mm

Dielectric Constant: er

Volume Resistivity(20°C): 1.0*10(12)Ω.cm

Application industry:

Machinery, electronic, semiconductor, chemical, petroleum, smelt.

Specific application:

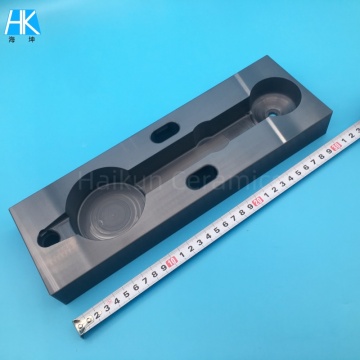

Welding shaft, electronic substrate, plunger, nozzle, slide guide, diesel parts, metal molding, shaft wheels etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

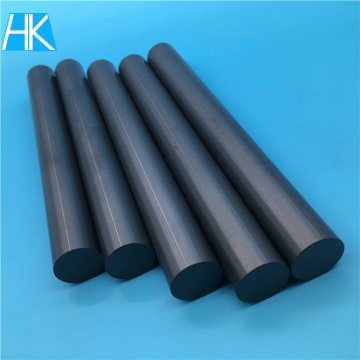

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.