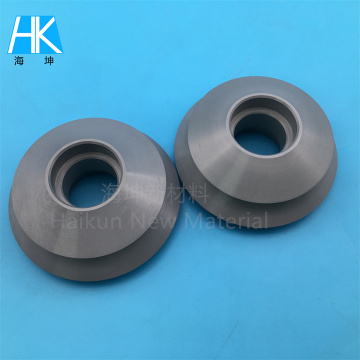

isolating macor mica ceramic mouth pipe bush ferrule

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

custom made isolating macor mica ceramic mouth pipe bush ferrule

Reputation depends on quality, quality comes from Hard!

Macor Glass Machinable Glass Ceramic:

Reinforced plastic raw materials can be divided into granular (such as calcium plastic reinforced plastic), fiber (such as glass fiber or glass cloth reinforced plastic), and flake (such as mica reinforced plastic). According to the material, it can be divided into cloth-based reinforced plastic (such as rag reinforced or asbestos reinforced plastic), inorganic mineral filled plastic (such as quartz or mica filled plastic), and fiber reinforced plastic (such as carbon fiber reinforced plastic). Foam can be divided into three types: rigid, semi-rigid and flexible foam. Rigid foam plastic has no flexibility, and its compression hardness is very large. It will deform only when it reaches a certain stress value and cannot return to its original state after stress is relieved. Flexible foam plastic is flexible, with low compression hardness, and is easy to deform. Restore to its original state, with less residual deformation; the flexibility and other properties of semi-rigid foam are between rigid and soft foam. Thermoplastics (Thermo plastics): refers to plastics that will melt after heating, can flow into the mold after cooling, and then melt after heating; heating and cooling can be used to produce reversible changes (liquid ←→solid), yes The so-called physical change. General-purpose thermoplastics whose continuous use temperature is below 100°C, polyethylene, polyvinyl chloride, polypropylene, and polystyrene are also called the four general-purpose plastics. Thermoplastic plastics are divided into hydrocarbons, vinyls with polar genes, engineering, cellulose and other types. It becomes soft when heated, and becomes hard when cooled. It can be softened and hardened repeatedly and maintain a certain shape. It is soluble in certain solvents and has the properties of being meltable and soluble.

properties:

Good insulativity, high temperature(800°), good machinable property, can be made of rod and plate in short time.

Data Sheet↓

Color: WhiteDensity: 2.6g/cm3

Gas permeability: 0

Water Absorption: 0

Rockwell Hardness(45N): 40R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 108Mpa

Compressive Strength(20°C): 488Mpa

Modulus of Elasticity(25°C): 65Gpa

Thermal Conductivity(25°C):1.71W(m.K)

Thermal Expansion Coefficient: 7.2 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum Use Temperature: 800°C

Dielectric Strength: >30 KV/mm

Volume Resistivity(20°C): >10(16)Ω.cm

Application industry:

Machinery, electronic, limitary, aerospace etc.

Specific application:

Machined equipment high temperature insulated parts, electronic equipment high temperature insulated parts.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.