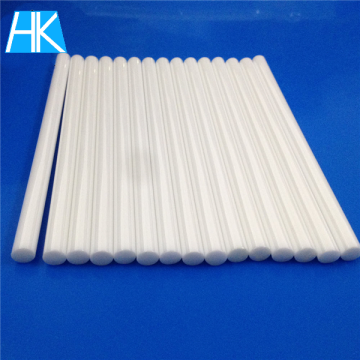

al2o3 alumina ceramic pin piston plunger customized

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

Alumina Ceramic Components: Precision Engineered Pins, Pistons, and Plungers That Solve Even the Craziest Problems

Wherever performance, endurance or accuracy matter the most, alumina ceramic elements have become the most preferred materials. Of these, the Alumina Ceramic Roller, the alumina ceramic pins with a high degree of polish, and alumina insulating ceramic rods are the most commonly used because they are also broader.

Alumina Insulation Ceramic Rod consists of primarily Al2 O3. One of its outstanding values properties is the strength and hardness of crystalline structures over broad temperature ranges. Such properties make it suitable for inclusion in construction materials for components that will be operated in extreme conditions, which in most cases means high temperatures, liquid corrosion, and mechanical pressure. This makes reliable and durable pin, pistons, plungers in ceramics materials for whichever industries you're involved in, electronics, aerospace, automotive or industrial manufacturing.

The usage of all the above-stated components is due to the most favorable properties of the alumina ceramic components. The tolerances obtainable in such components are as high as 1mm which makes all the most finite components to be able to withstand the most aggressive conditions. This precision is essential for industries where component fit and performance are critical, such as in electronic devices, where even slight variations can impact functionality.

Data Sheet↓

Density: 6.0g/cm3

Zirconia Content: 94.4%

Gas permeability: 0

Water Absorption: 0

Crystal Size: 0.5um

Rockwell Hardness(45N): 78R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 800Mpa

Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): 9.0 MPam1/2

Thermal Conductivity(20°C-400°C): 2.5W(m.K)

Thermal Expansion Coefficient: 9.6 10-6/°C

Thermal Shock Resistance: 250 △T°C

Application industry: Machinery, electronic, chemical, petroleum etc.

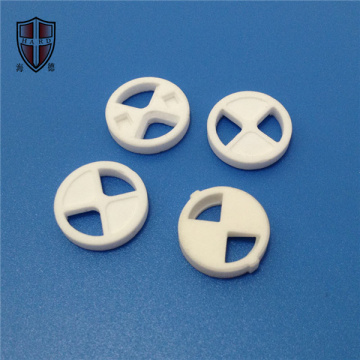

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

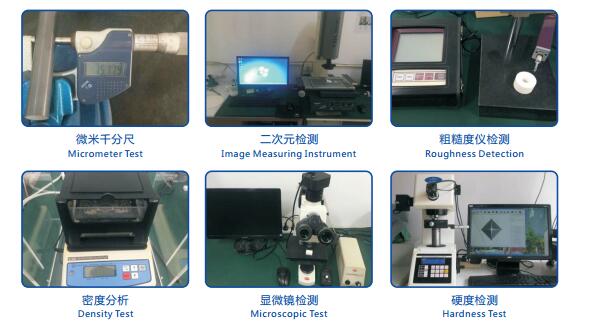

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Show time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

Products Show

Factory Show

Our Team

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.