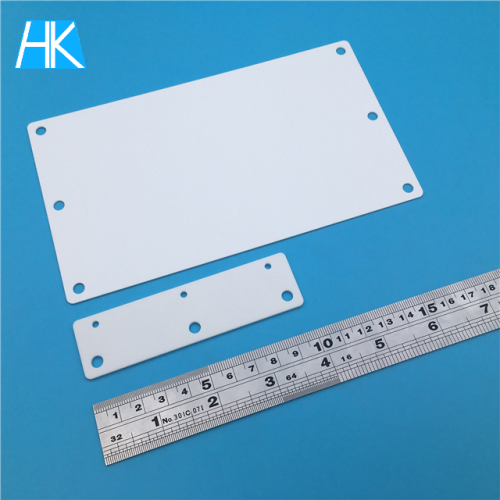

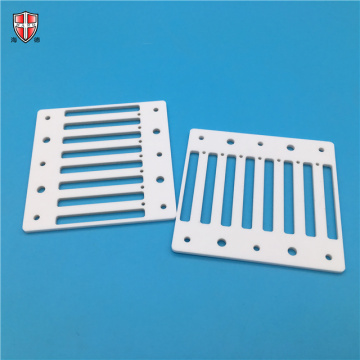

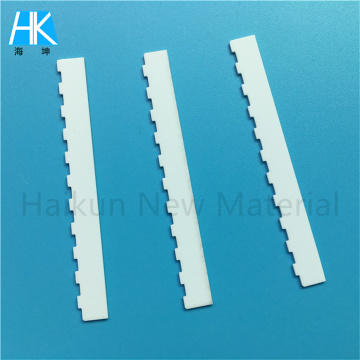

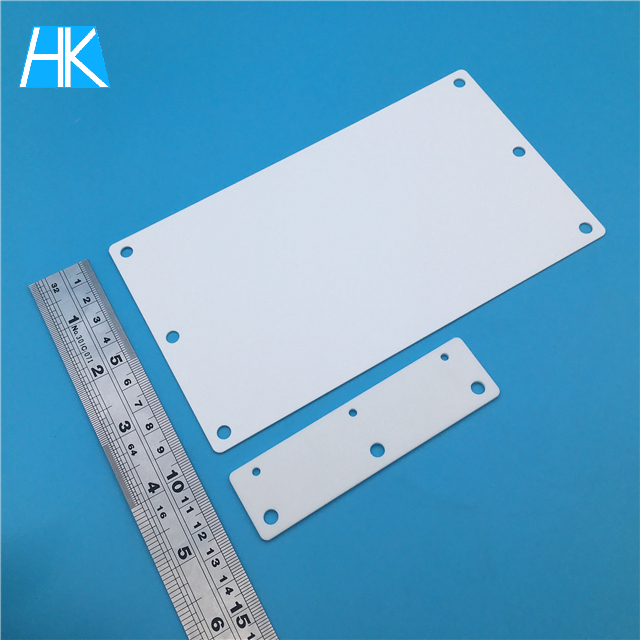

conductivity 95 96 alumina ceramic fixture sheet substrate

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

conductivity 95 96 alumina ceramic fixture sheet substrate

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

Alumina ceramic gas phase method, ethylene polymerizes in gaseous state, generally a fluidized bed reactor is used. There are two types of catalysts: chromium series and titanium series, which are quantitatively added into the bed from a storage tank, and high-speed ethylene is circulated to maintain the fluidization of the bed and remove the heat of polymerization. The polyethylene produced is discharged from the bottom of the reactor. The pressure of the reactor is about 2 MPa, and the temperature is 85-100°C. The gas phase method is the most important method for the production of linear low-density polyethylene. The gas phase method eliminates the solvent recovery and polymer drying processes, and saves 15% of the investment and 10% of the operating cost compared with the solution method. It is 30% of the investment of the traditional high pressure method and 1/6 of the operating cost. As a result, it has developed rapidly. However, the gas phase method needs further improvement in product quality and variety. Using a chromium catalyst supported on silica gel, ethylene is polymerized under medium pressure in a loop reactor to produce high-density polyethylene.

Processing and application It can be processed by blow molding, extrusion, injection molding, etc. It is widely used in the manufacture of films, hollow products, fibers and daily sundries. In actual production, in order to improve the stability of polyethylene to ultraviolet rays and oxidation, and improve processing and use performance, a small amount of plastic additives must be added. Commonly used ultraviolet absorbers are o-hydroxybenzophenone or its alkoxy derivatives, etc. Carbon black is an excellent ultraviolet shielding agent. In addition, antioxidants, lubricants, colorants, etc. are also added to expand the application range of polyethylene. High-pressure polyethylene: More than half is used for film products, followed by pipes, injection molded products, wire wraps, etc.

Low and medium pressure polyethylene: mainly injection molded products and hollow products.

Ultra-high-pressure polyethylene: Due to the excellent comprehensive properties of ultra-high molecular polyethylene, it can be used as engineering plastics.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.