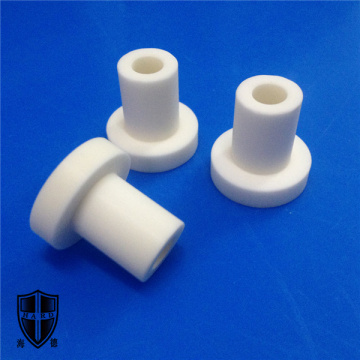

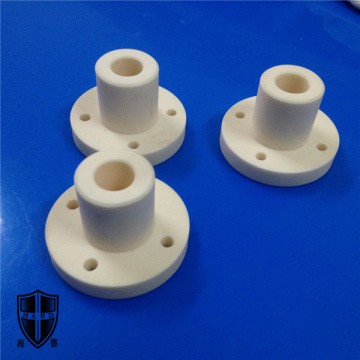

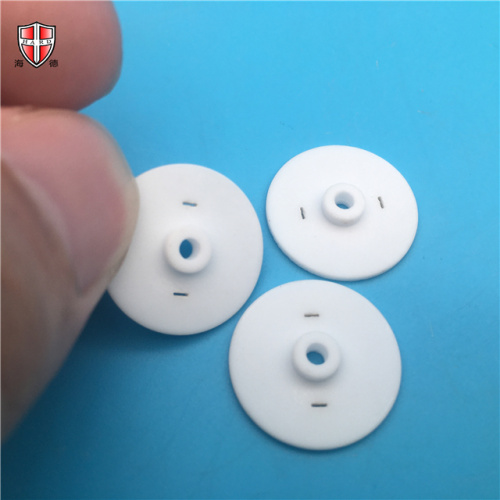

high advanced 95% alumina white ceramic disc disk

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

high advanced 95% alumina white ceramic disc disk

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

Alumina ceramic chlorosulfonated polyethylene "When polyethylene reacts with chlorine containing sulfur dioxide, part of the hydrogen atoms in the molecule are replaced by chlorine and a small amount of sulfonyl chloride groups to obtain chlorosulfonated polyethylene. The main industrial manufacturing method is the suspension method. Chlorosulfonated polyethylene is resistant to ozone, chemical corrosion, oil, heat, light, abrasion and tensile strength. It is an elastomer with good comprehensive performance and can be used to make food-contact equipment parts. Cross-linked polyethylene uses radiation method (X-ray, electron beam or ultraviolet radiation, etc.) or chemical method (peroxide or silicone cross-linking) to make linear polyethylene into a network or body-shaped cross-linked polyethylene. Among them, the silicone cross-linking method has a simple process, low operating cost, and molding and cross-linking can be carried out step by step, and blow molding and injection molding are suitable. The heat resistance, environmental stress cracking resistance and mechanical properties of cross-linked polyethylene are greatly improved than polyethylene, and it is suitable for large-scale pipes, cables and wires, and rotomolding products.

Blending modification of polyethylene After blending linear low-density polyethylene and low-density polyethylene, it can be used to process films and other products. The product performance is better than low-density polyethylene. The blending of polyethylene and ethylene-propylene rubber can produce a wide range of thermoplastic elastomers. Polyethylene can be divided into high pressure method, medium pressure method, and low pressure method according to polymerization pressure.

The high-pressure method is used to produce low-density polyethylene. This method was developed early. The polyethylene produced by this method has so far accounted for about 2/3 of the total polyethylene output, but with the development of production technology and catalysts, its growth rate has increased. Far behind the low-pressure law. The low pressure method includes slurry method, solution method and gas phase method. The slurry method is mainly used to produce high-density polyethylene, while the solution method and gas phase method can not only produce high-density polyethylene, but also produce medium and low-density polyethylene by adding comonomers, which is also called linear low-density polyethylene. Vinyl. Various low-pressure processes have developed rapidly.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.