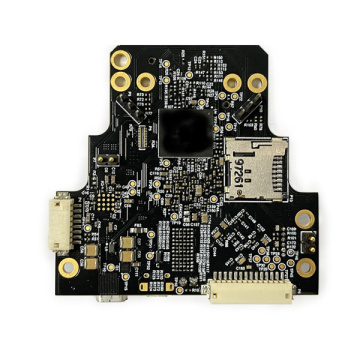

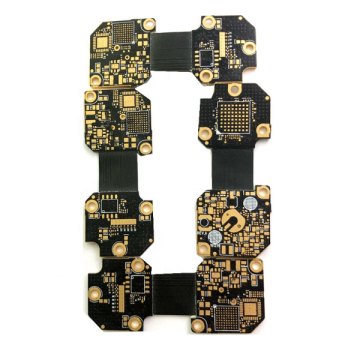

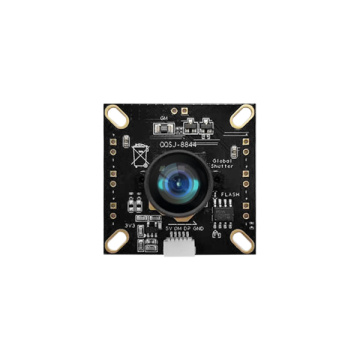

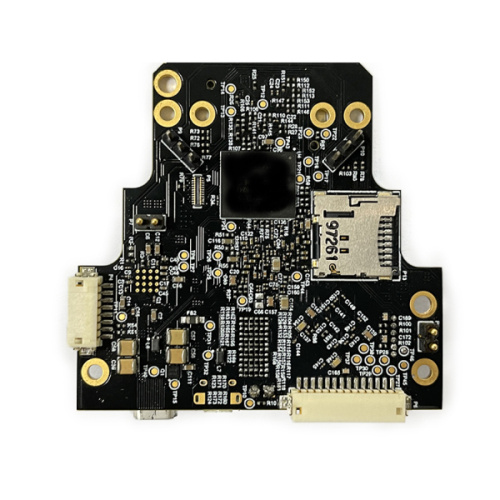

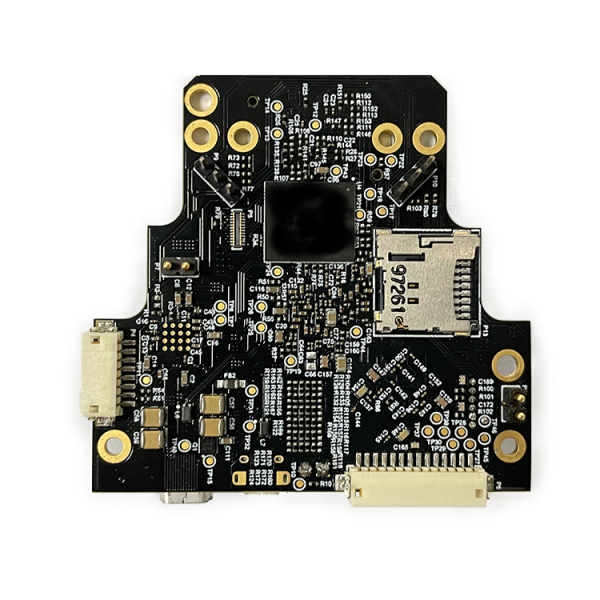

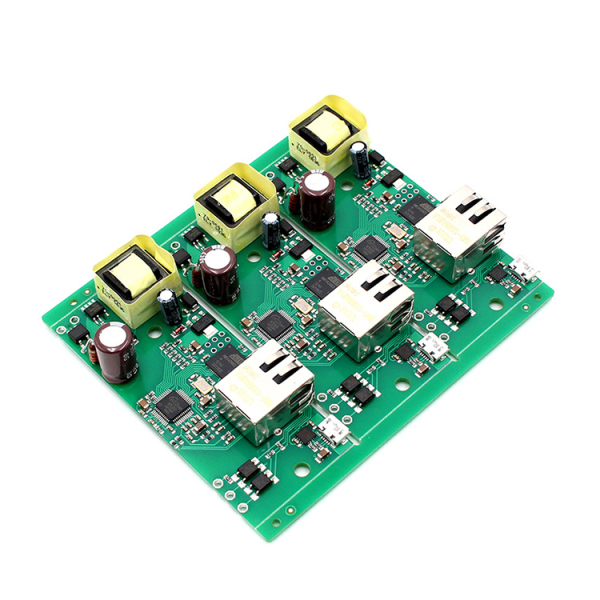

Custom Electronic PCB&PCBA Project

-

$32.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowWhat are the components of PCBA processing costs and how to calculate?

PCBA processing cost is composed of the following parts:

PCB board fee (if you provide it yourself, then no money will be charged)

Component purchase fee (If you provide this by yourself, then no money will be charged)

SMT processing fee (SMD patch + DIP post welding)

PCBA test fee and assembly fee

One, PCB board fee

If you want to find a PCBA processor to help you process it, then you have to provide the PCB file and BOM list, and the PCBA processor will help you make the bare PCB board according to your PCB file. At this time, the first part of the cost will be incurred, the PCB board. fee. The cost of the PCB board is determined by the difficulty of the board. For example, 4-layer board, 8-layer board, aluminum substrate, carbon ink board, the prices of these boards are different. Of course, you can also find a PCBA board factory for processing. The price is definitely not that cheap. After all, someone else has a long-term cooperation. There must be a discount. The local tyrants please feel free.

The second part of PCBA patch processing costs, component procurement costs. The processing manufacturer purchases the components you need according to the BOM. When the components are purchased, due to the loading of the disk such as resistors and capacitors and the loss of the SMT patch (such as the wrong board, the tape is not cleared in time, etc.), it needs to be covered About 5% of material loss rises; processing manufacturers have long-term cooperation with component manufacturers, so the price will be lower.

When calculating the SMT processing fee, you must first see how large your processing batch is. If it is greater than 2000 pic, there is no need to charge engineering fees, otherwise, additional engineering fees will be charged. Next, calculate the number of points and multiply the unit price of the points. The unit price of the patch points is between 0.01-0.015 yuan. The calculation of the points is calculated according to the SMT patch material 2 feet and 1 point, and the DIP plug-in 1 foot and 1 point. Multiply the two together.

PCBA test fee is generally calculated at 2 yuan per board, plus PCBA assembly and packaging costs, generally 0.8 yuan/piece, this is the fourth part of the cost.

Now, add up the cost of the above four parts, it is the PCBA processing cost!