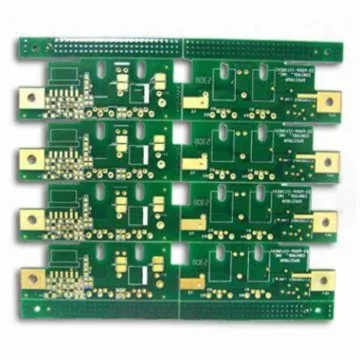

pcb factory Mixed Assembly

-

$9.80≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Express, Others, Air

- Port:

- shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 10000pcs/day |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,EXW |

| Transportation: | Ocean,Land,Express,Others,Air |

| Port: | shenzhen |

What is mixed mode assembly?

PCB AMixed Assembly refers to the degree of difference in the assembly process of various packages on the PCBA mounting surface. Specifically, the degree of difference between the process method used and the thickness of the stencil for various package assembly. The greater the degree of difference in Mixed Assembly process requirements, the greater the degree of mixing, and vice versa; the greater the degree of mixing, the more complicated the process and the higher the cost.

PCBA Mixed Assembly reflects the complexity of the assembly process. The PCB Assembly products that we usually talk about are "good soldering", which actually means two layers. One layer means whether there are components on the PCBA with a narrow process window, such as fine-pitch components; the other layer means PCBA installation The degree of difference in various packaging assembly processes on the surface.

The higher the mixing degree of PCBA, the more difficult it is to optimize the process of PCB Assembly products of each type of package, and the worse the processability. For example, such as mobile phone PCBA, although the components used on the mobile phone board are fine-pitch or small-size components, such as 01005, 0201, 0.4CSP, POP, the assembly of each package is very difficult, but their craftsmanship The requirements belong to the same level of complexity, the mixed assembly of the process is not high, each package process can be optimized design, the final PCB Assembly yield rate will be very high; and the communication PCBA, although the component size used is relatively large , But the mixed assembly of the process is relatively high, and the stepped steel mesh is required for PCB assembly. Due to the limitation of the component layout gap and the difficulty of stencil production, it is difficult to meet the individual needs of each package. Therefore, the final process plan is often a compromise plan that takes care of various packaging process requirements, rather than the most optimized plan. The assembly yield rate will not be very high. This fact also shows that the concept of PCBA mixing degree is extremely important. A package with similar installation process requirements on the same assembly surface is the basic requirement for package selection. In the hardware design stage, establishing a suitable package is the first step in the design for manufacturability.