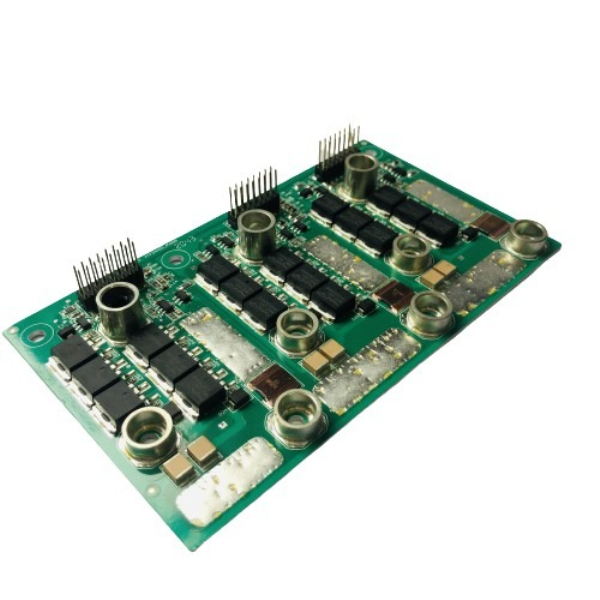

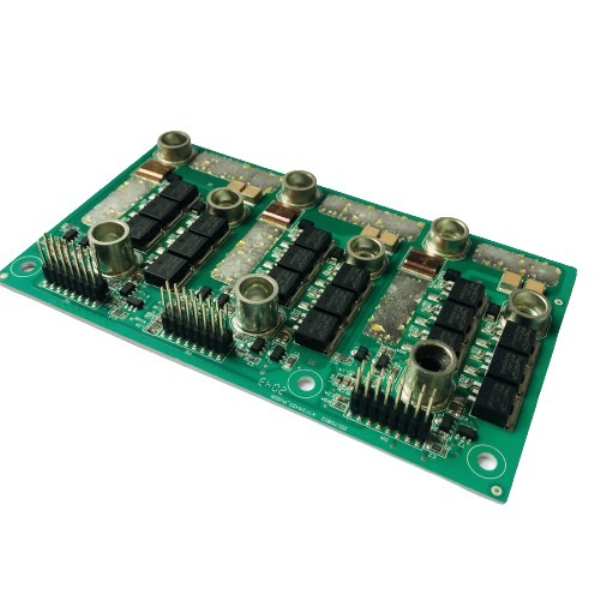

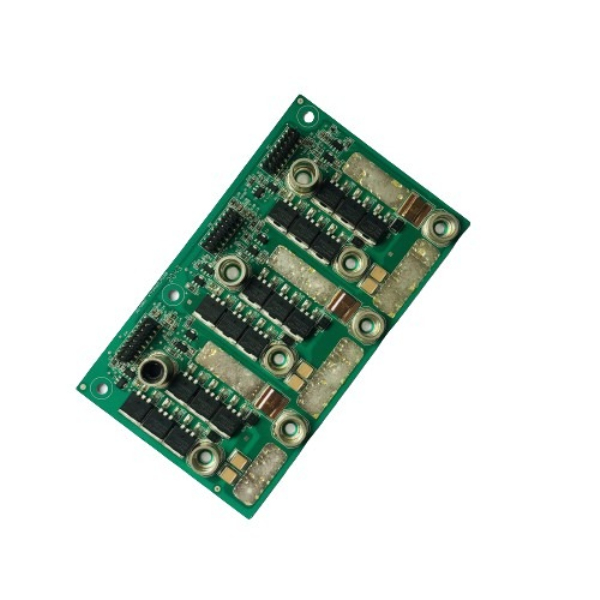

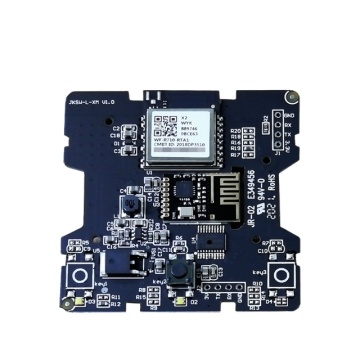

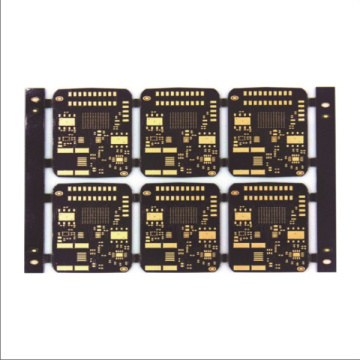

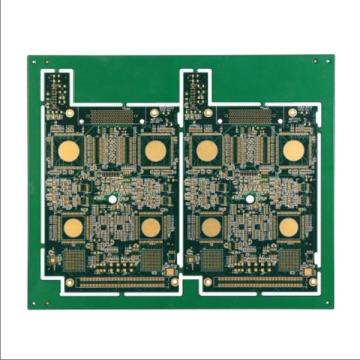

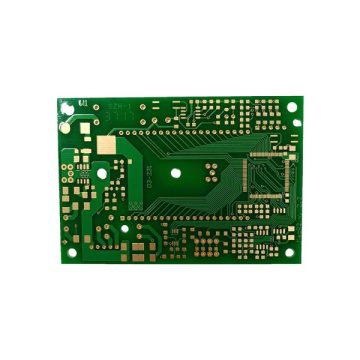

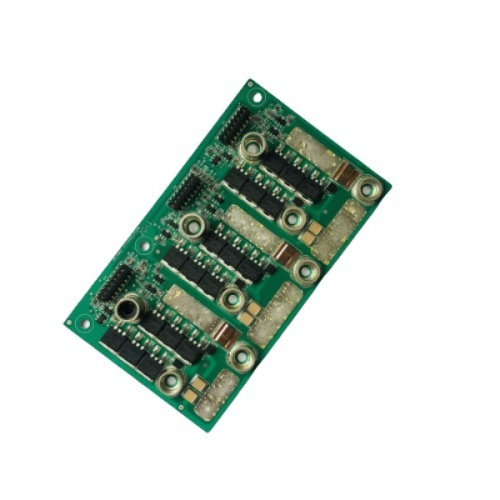

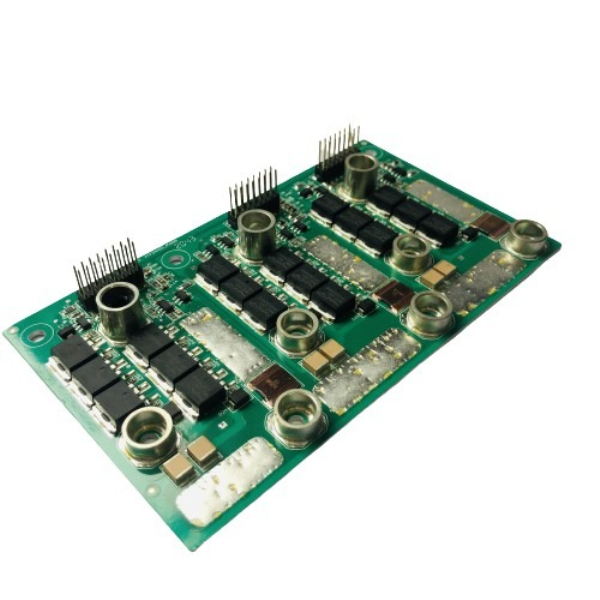

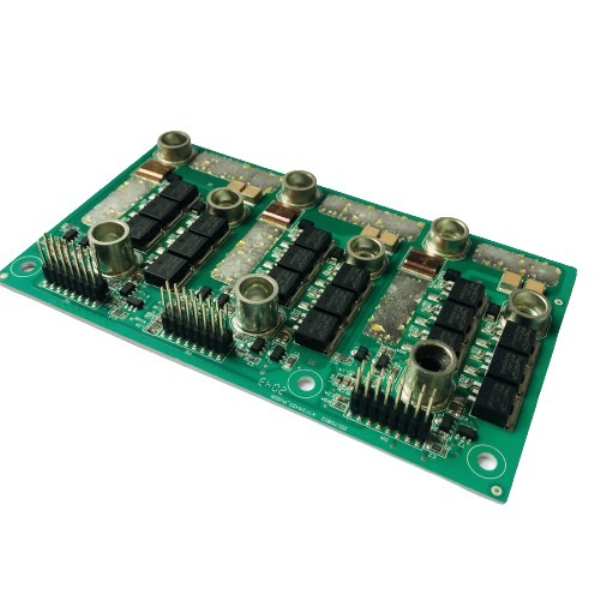

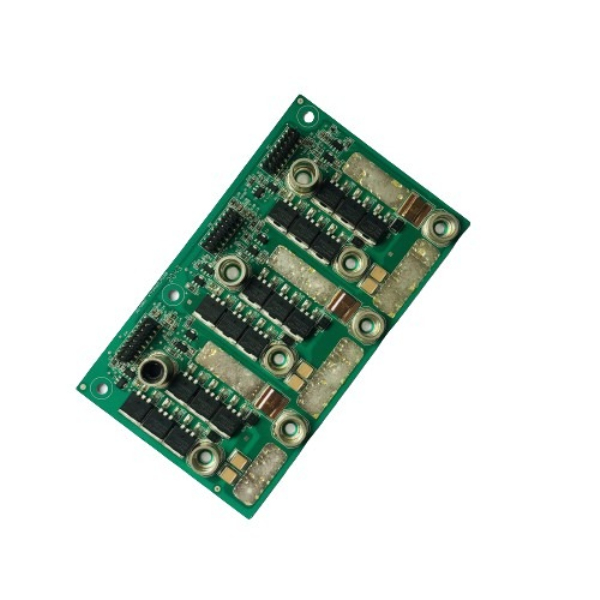

Smart Bms Hdi Buried Blind PCB Powerbank PCBA

-

$0.99≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

What does PCB assembly mean?

The assembly or manufacturing process of a printed circuit board (PCB) includes many steps. All these steps should go hand in hand to achieve good PCB assembly (PCBA). The synergy between one step and the previous step is very important. What steps are involved in the PCB assembly process?

Step 1: Add solder paste: This is the initial stage of the assembly process. At this stage, solder paste is added to the electronic components pads wherever soldering is required. Put the solder paste on the pad and paste it in the correct position with the help of the soldering screen. This screen is made of PCB files and has holes.

Step 2: Place components: Perform Surface-Mount (SMT) &BGA Assembly.

Step 3: Reflow oven: This step is used to permanently fix the components on the board. After placing the components on the board, the PCB passes through the reflow oven conveyor belt. The controlled heat of the oven melts the solder added in the first step, thereby permanently connecting the components.

Step 4: Wave soldering: In this step, the PCB is passed through a wave of molten solder. This will establish electrical connections between the solder, PCB pads and component leads.

Step 5: Cleaning: Up to this step, all soldering processes of Wave Solder for PCBA have been completed. During the soldering process, a large amount of flux residue will form around the solder joints. As the name suggests, this step involves cleaning flux residues. Clean the flux residue with deionized water and solvent. Through this step, PCB Mixed Assembly is completed. The next steps will ensure that the assembly is completed correctly.

Step 6: Testing: At this stage, the PCB Mixed Assembly is completed, and inspections are started to test the location of the components. This can be performed in two ways:

1. Manual: This kind of inspection is usually carried out for smaller components, and the number of components does not exceed one hundred.

2. Automatic: Perform this check to check whether there are bad joints, wrong components, wrongly placed components, etc.

Step 1: Add solder paste: This is the initial stage of the assembly process. At this stage, solder paste is added to the electronic components pads wherever soldering is required. Put the solder paste on the pad and paste it in the correct position with the help of the soldering screen. This screen is made of PCB files and has holes.

Step 2: Place components: Perform Surface-Mount (SMT) &BGA Assembly.

Step 3: Reflow oven: This step is used to permanently fix the components on the board. After placing the components on the board, the PCB passes through the reflow oven conveyor belt. The controlled heat of the oven melts the solder added in the first step, thereby permanently connecting the components.

Step 4: Wave soldering: In this step, the PCB is passed through a wave of molten solder. This will establish electrical connections between the solder, PCB pads and component leads.

Step 5: Cleaning: Up to this step, all soldering processes of Wave Solder for PCBA have been completed. During the soldering process, a large amount of flux residue will form around the solder joints. As the name suggests, this step involves cleaning flux residues. Clean the flux residue with deionized water and solvent. Through this step, PCB Mixed Assembly is completed. The next steps will ensure that the assembly is completed correctly.

Step 6: Testing: At this stage, the PCB Mixed Assembly is completed, and inspections are started to test the location of the components. This can be performed in two ways:

1. Manual: This kind of inspection is usually carried out for smaller components, and the number of components does not exceed one hundred.

2. Automatic: Perform this check to check whether there are bad joints, wrong components, wrongly placed components, etc.