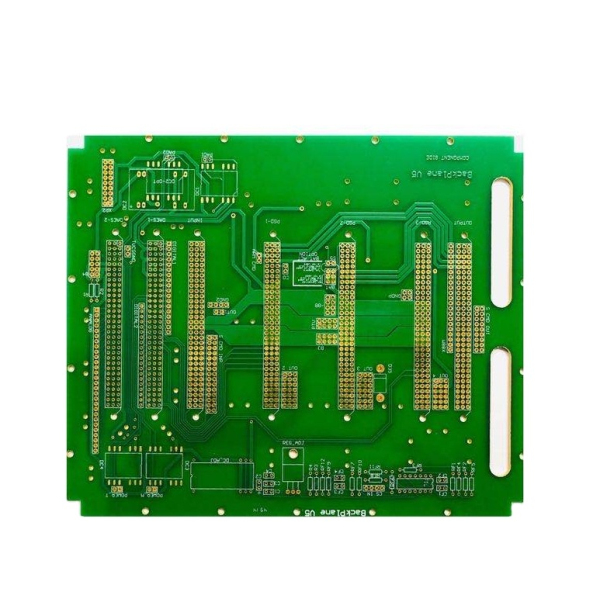

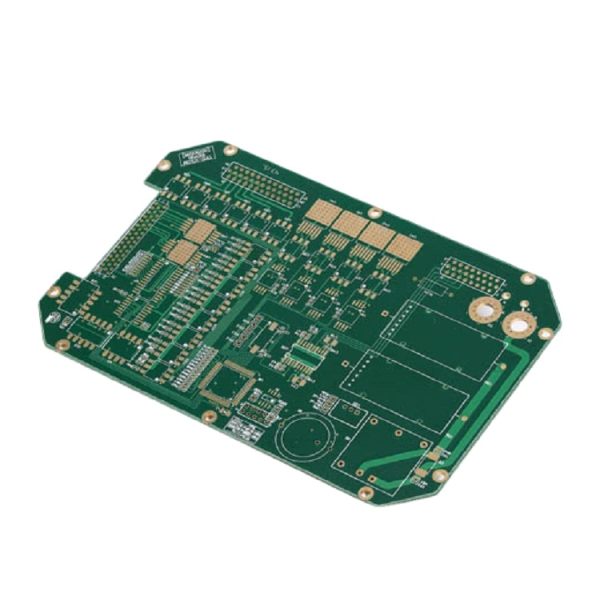

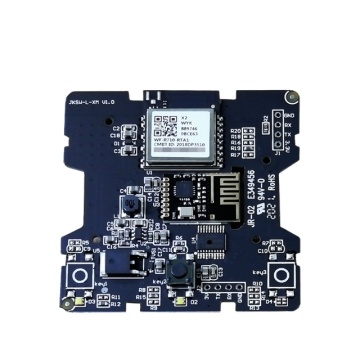

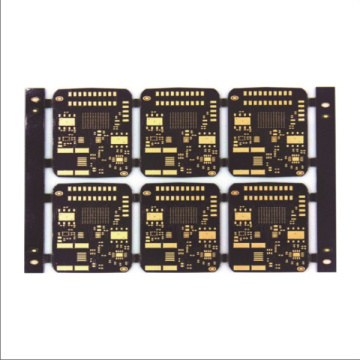

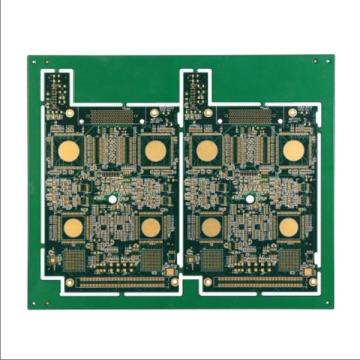

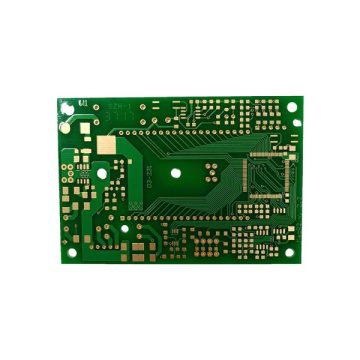

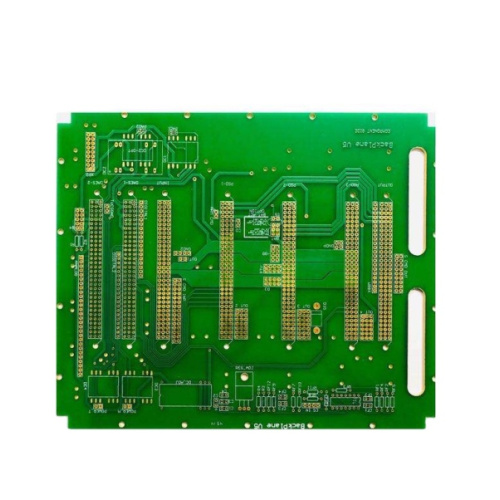

High temperature resistant plate laser drilling hdi pcb

-

$19.90≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowWhat causes a PCB to overheat?

There are many reasons for the overheating of the PCB. The MCU development engineer explained that under normal circumstances, if the design is defective, the appropriate Electronic Components and materials are not selected, the misplacement of the components and the poor heat dissipation may cause the PCB on the printed circuit board (PCB). Too much heat.

In origin electronics IC, too high temperature will have a negative impact on the function, PCBA and circuit board itself. The effect of high temperature is negligible in many applications, but in high-performance designs, the effect can be significant.

Therefore, proper heat management is an important step in electrical engineering. To manage heat well, this involves all aspects from the component level to the physical board system and operating environment.

1. Electronic Components are not placed correctly

The MCU development engineer said that some high-power devices need to reserve a place for natural ventilation or forced ventilation to dissipate heat.

If there is no proper airflow to dissipate heat, the PCB will accumulate most of the heat, resulting in a gradual increase in temperature, resulting in degradation or damage to the circuit. In addition, it should be noted that sensitive components cannot be placed near components that emit a lot of heat.

2. Environment and external thermal factors

When the PCB is used in an extreme temperature environment, in the design process, if the temperature conditions in the target environment are not considered, the PCBA may be subjected to excessive pressure.

3. Wrong selection of parts and materials

In the process of electronic component material selection, failure to follow the recommended usage guidelines may cause heat dissipation problems. When selecting Electronic Components materials, it is important to review detailed data and consider all relevant information related to power consumption, thermal resistance, temperature limits, and cooling technology.

In addition, make sure to select the power rating suitable for the application. An easy mistake to make is to use the same resistor over and over again (perhaps because the corresponding component is already in your CAD library), although some applications may require higher power ratings. Perform a quick power calculation on the resistor and ensure that its rating is much higher than the maximum expected loss.

Another important issue is the choice of PCB dielectric materials. The printed circuit board itself must be able to withstand the worst-case thermal conditions.

Four, PCB design and manufacturing defects

Poor layout and manufacturing processes can cause PCB thermal problems. Improper PCBA manufacturing may hinder heat dissipation, and insufficient trace width or copper area will cause temperature rise.

To prevent heat dissipation problems, designers must reduce heat dissipation and use other cooling techniques when natural cooling is insufficient. Thermal optimization design requires attention to component specifications, PCB layout, PCB dielectric materials and environmental conditions.