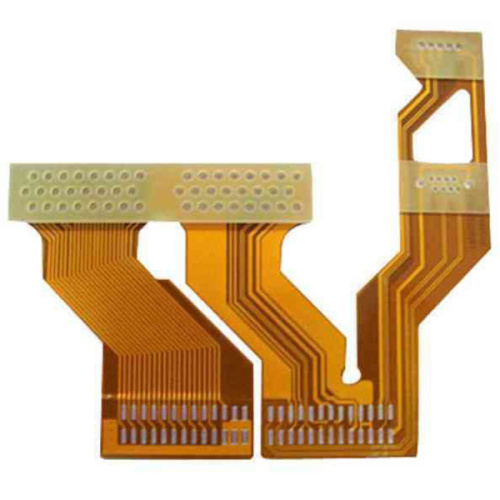

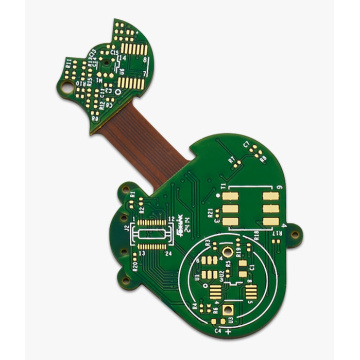

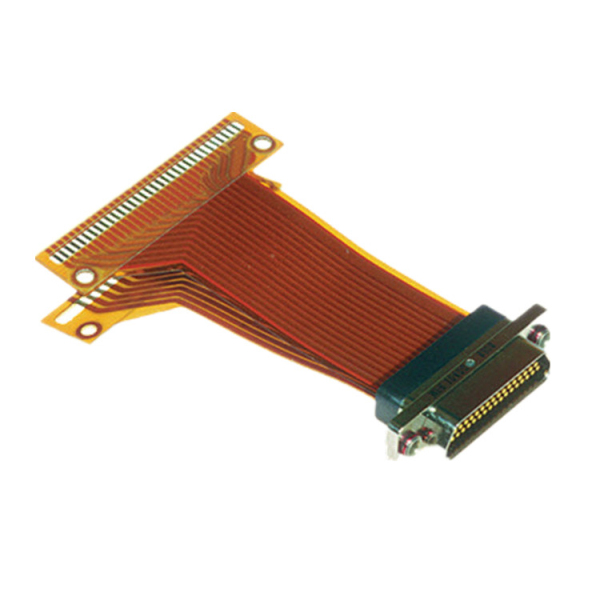

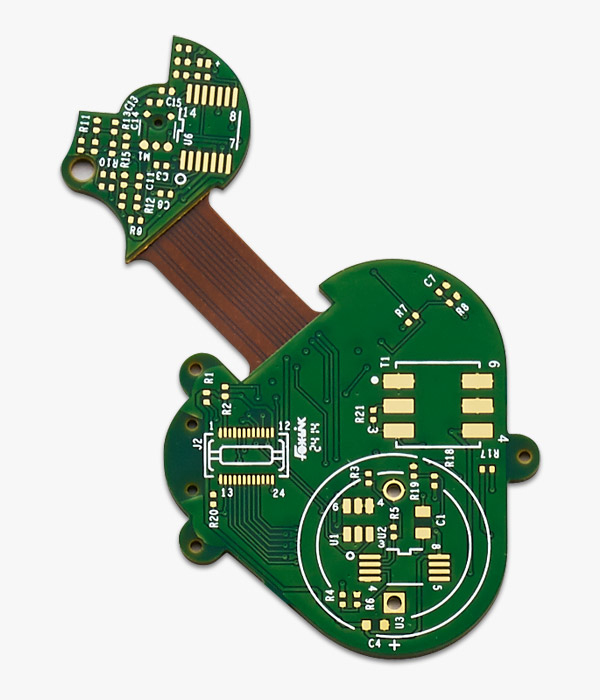

flat flex pcb flex pcb assembly

-

$6.10≥5 Piece/Pieces

- Min. Order:

- 5 Piece/Pieces

- Min. Order:

- 5 Piece/Pieces

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

How to assemble a flexible PCB?

When PCBA Manufacturing performs SMT placement, a common method to "change" a flexible circuit board into a rigid board is to use a carrier board (tray). To fix the flexible circuit board on the carrier board, two problems need to be solved: positioning problem and fixing problem.

At present, the flexible board is accurately pasted on the carrier board, and the positioning tool with positioning pins is used (the two positioning posts are actually useful), and then the positioning tray is taken away, just a temporary positioning effect.

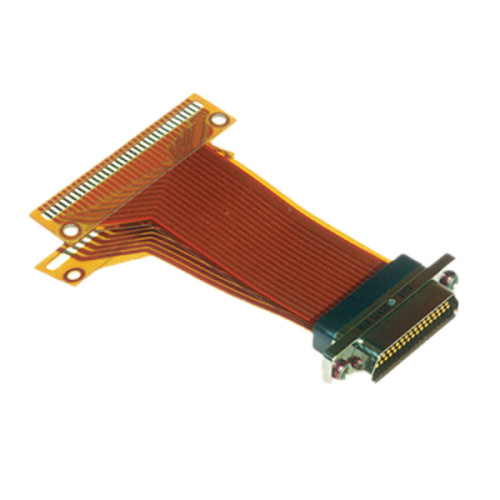

There are currently three main methods for fixing flexible circuit boards:

(1) Magnetic tray and cover plate (0.05mm thick stainless steel sheet): Generally used in the case where the chip PCB assembly is relatively large and is not sensitive to the amount of solder paste, and has the characteristics of low cost.

(2) Silica gel paper (reused many times, generally can be used for 24 hours): It is a relatively advanced process method, the surface of the patch is flat, but there are not many manufacturers that can provide sources of goods, only South Korea and Japan have two. Generally, a thickness of silica gel paper is dug under the place where the silica gel is pasted on the carrier board to ensure the flat surface of the flexible circuit.

(3) High temperature tape (high temperature resistance, no residual glue): more troublesome and time-consuming.

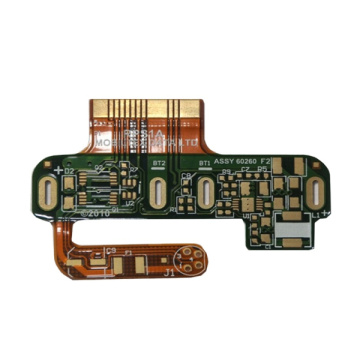

(1) Eliminate the intermediate packaging;

(2) It is produced in the way of jigsaw, with high efficiency.

Self-produced, generally accepted as a single circuit board, Surface-Mount (SMT) & BGA Assembly needs to be placed and removed one by one, which is very troublesome. If it is produced by the jigsaw method, it is necessary to purchase a punching machine and design and manufacture a special mold.