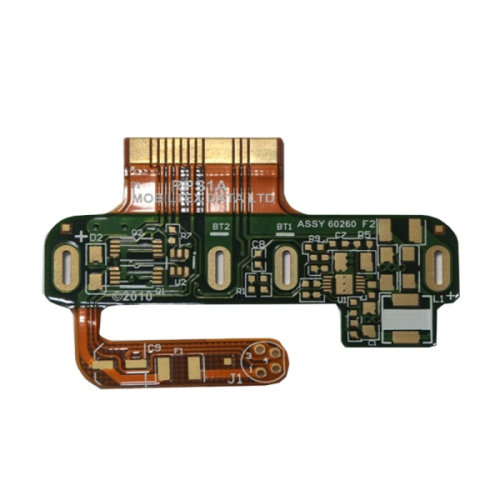

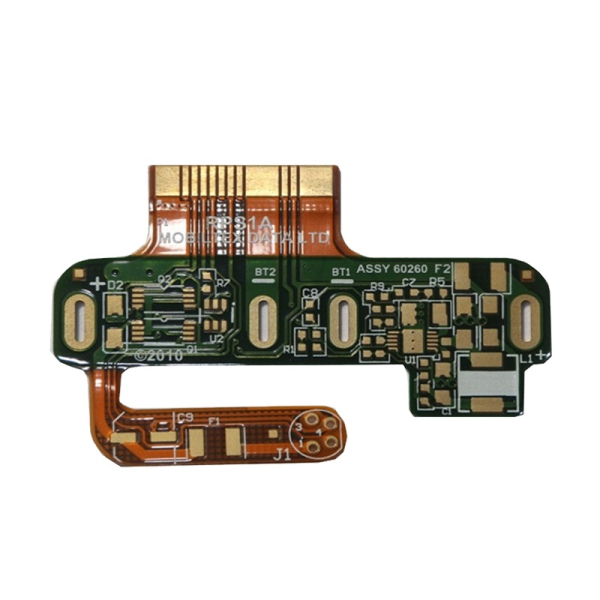

One-Stop Solution Rigid Flex PCB Board

-

$6.10≥5 Piece/Pieces

- Min. Order:

- 5 Piece/Pieces

- Min. Order:

- 5 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowWhat is the difference between single-layer PCB and multi-layer PCB?

Single-layer and multi-layer PCBs: what is the difference?

You can guess the significant difference between these two PCBs based on the name. A single-layer board has only one layer of base material, also called a base, while a multi-layer PCB has multiple layers. Once you take a closer look at the three main types of PCB boards, you will find how they differ in their construction methods and functions.

1. Single layer PCBS

Single-layer boards, sometimes called single-sided boards, have components on one side of the board and conductor patterns on the other side. They have only one layer of conductive material, usually copper. The single-layer board includes a base layer, a conductive metal layer, and then a protective solder mask and screen. You can find single-layer boards in many simpler electronic devices.

2. Double-sided printed circuit board

You can also use double-layer or double-sided circuit boards, which have more layers than single-layer circuit boards but less than multi-layer circuit boards. Double-sided PCBs, such as single-sided variants, have a base layer. The difference is that they have a layer of conductive metal on both sides of the substrate.

3. Multilayer PCB

Multi-layer PCBs are stacked by three or more double-sided boards. In theory, they can contain as many boards as you need, but the largest board ever is 129 layers thick. Usually, they have an even number between 4 and 12 layers-odd numbers can cause problems such as warpage and distortion after soldering.

• Mass production: The difficulty of producing these plates means that you can order these plates in large quantities without problems. Because higher quantities will reduce the price of each board, bulk ordering is one of the best ways to get the most value from a single-sided PCB.

• Short delivery time: Single-layer boards can be manufactured quickly because they are simple and they require fewer resources than multilayer PCBs. This makes them an ideal choice when PCBs can be obtained quickly even in mass production.

Disadvantages of single-layer PCB

Despite their cost advantages and other advantages, single-layer boards are not the right choice for every project due to their limitations, including:

•Simple design: The simplicity of single-layer boards is one of their greatest benefits, but it is also a big limitation. For more complex devices that require more components and connections, a single layer cannot provide enough space or power. If the wires cross each other, the device will not work properly, so it is important that the circuit board has enough space to accommodate all the devices. More complex designs cannot be applied to single-sided PCBs.

• Slower speed and lower operating capacity: The limited number of connections on these circuit boards will also affect their power and speed. These less dense designs are not as robust as designs with more circuits and lower operating capacity. They may not have enough power for certain applications.

• Larger size and higher weight: To add functionality to a single panel, you need to expand its size instead of adding another layer, just like you can use a multi-layer PCB. You can use multiple individual boards, but a multi-layer board may handle the same requirements. Increasing the size or number of circuit boards in the device will also increase the weight of the final product.

Single-layer PCB: weighing the pros and cons

To determine whether a single-layer PCB is right for you, you need to consider the requirements of the project and whether the single-sided board has the functions required to meet these requirements. For simpler equipment, they are usually the preferred board due to their low cost and fast production time. However, for more complex projects, they often fail to provide sufficient functionality.

What are the differences between single-layer and multi-layer PCBs and their respective advantages and disadvantages

Before deciding to use single-layer PCBs, please weigh their advantages and disadvantages. All in all, the advantages and disadvantages of single-layer PCB include:

advantage:

•Low cost pcb manufacturing

• Simpler design and production

• Capable of mass production

• Shorten the lead time

shortcoming:

• Complex projects are too simple

• Decreased operational capacity

• slower

• Larger size

•Higher weight

Is single-sided PCB right for you? If they meet your project criteria and the above expertise outweighs the disadvantages, they may be.

Single layer PCB application

These circuit boards have become popular choices for various electronic products due to their low cost and relatively easy production. Although 1-8layer Fast PCB fabrication multilayer circuit boards are catching up as electronic circuits become more and more complex, single-layer circuit boards have historically been the most common type. They often appear in devices with a specific function that do not need to store large amounts of data or access the Internet, but this is not always the case.

Although single-layer circuit boards have their advantages, multi-layer designs are more advantageous for certain applications. For some devices, it is even necessary to have multiple layers. The benefits of more complex multilayer PCBs include:

• Useful for more complex projects: devices that are more complex and involve more circuits and PCB assemblies usually require the use of multilayer PCBs. If it needs more circuits than can fit on a single circuit board, you can add space by adding layers. Having multiple circuit boards ensures sufficient connection space, making it an ideal choice for more advanced equipment. Devices with many different uses and advanced features, such as smartphones, require this level of complexity.

• High quality: Multi-layer circuit boards require more planning and intensive production processes, so they usually have higher quality than other types of circuit boards. Designing and producing these circuit boards requires more skills and more advanced tools than simple components, thereby increasing the possibility of obtaining high-quality products. Many of these designs include advanced controlled impedance characteristics and electromagnetic interference shielding to further improve performance.

What are the differences between single-layer and multi-layer PCBs and their respective advantages and disadvantages

• Increased power: Due to the increased circuit density of multilayer PCBs, they are more powerful than less complex designs. They have higher operating capacity and can run at higher speeds, which is usually necessary for the advanced equipment they power and can improve performance.

• Improved durability: Having more layers means that the circuit board is thicker and therefore more durable than a single-sided PCB. This is another reason why adding functionality through additional layers is better than increasing the size of a single layer. This enhanced durability means that the circuit board can withstand harsher conditions and can generally last longer.

• Smaller size and lighter weight: Multi-layer PCBs achieve this enhanced durability while still maintaining a relatively small size and lighter weight. Because they will be stacked together, you can compress more functions into a more compact space than other boards. This smaller size also means lighter weight. The single-layer board must be very large to match the function of the multilayer board. You can even use multiple single-layer boards to match it, but this will also increase the size and weight of the final product.

•Single connection point: The use of multiple PCB assemblies requires multiple connection points. On the other hand, multi-layer boards are designed to work with a single connection point, simplifying the design of electronic devices and further reducing weight. Multi-layer boards are usually the best choice when deciding whether to use multiple single-sided boards instead of just one multilayer printed circuit board.

Layer PCB disadvantages

However, the enhancements and other benefits provided by multilayer boards come at a price. These shortcomings mean that they may not be ideal for every type of project. They include:

• Higher cost: It is more expensive to design and manufacture a circuit board with multiple layers than to make a circuit board with only one or two layers. It requires more resources, more time and more skills, which drives up prices. Always ensure that the advantages of multi-layer components outweigh the costs. If you don't need more than two layers, you may need to stick to a single-layer PCB.

What are the differences between single-layer and multi-layer PCBs and their respective advantages and disadvantages

• More complex design and production: The design and production of multi-layer boards is more complicated and more complicated than manufacturing single-layer boards. This means you need highly skilled designers and manufacturers with professional equipment. You are also more likely to encounter difficulties throughout the process, especially if you do not have the necessary resources available.

• Low availability: Due to the need for specialized multilayer boards, not every manufacturer or supplier can reliably produce or provide them. You may find it more difficult to find the right company to design, manufacture or repair circuit boards with a large number of layers. If the circuit board needs repair, it may also be more difficult to find someone who can fix it.

•Longer delivery time: The design and production of multi-layer circuit boards also takes more time than the production of single-layer circuit boards. There are more components to consider, and all components must be fixed to each other to form a board outside of each layer. These processes also involve more, which increases the lead time. If you need Quick Turn PCB, using multi-layer PCB may not suit you. If an error occurs during the production process or you want to change the design, the reprocessing may be very time-consuming, and it may not be possible if the parts are not replaced, thereby increasing material costs.

• More complex repairs: Multi-layer PCBs are relatively reliable, but if there is a problem, the complexity of its design will make repairs more difficult. If there is a problem with the Electronic Components or the circuit board is physically damaged, it may be more difficult to identify the problem because some inner layers and the vias connecting them are not visible from the outside. The number of components on the circuit board also makes repairs more challenging and time-consuming.

Multilayer PCB: Weigh the pros and cons

Is the multilayer printed circuit board suitable for your electronic equipment? If the devices are on the more complex end of the spectrum, they might be like this. However, be prepared to pay extra for the added features and other advantages. Consider the advantages and disadvantages of choosing a multilayer PCB, as well as the needs of the project and the resources you use to purchase the board. The advantages and disadvantages of multilayer PCBs include:

advantage:

• Ability to handle more complex functions

• Higher quality

• Greater power, operating capacity and speed

• Enhanced durability

• Smaller size and lighter weight

•Single connection point

shortcoming:

• Higher cost

• More complex design and production

• Limited availability

•Longer delivery time

• More complex repairs

Multilayer PCB application

With the advancement of technology, multilayer PCBs have become more and more common. The complex functions and small size of many electronic devices today require the use of multiple layers in their circuit boards. A series of equipment across industries use multilayer boards, especially those with multiple functions and more complex functions.

What are the differences between single-layer and multi-layer PCBs and their respective advantages and disadvantages

Multilayer printed circuit boards appear in many computer components, including motherboards and servers. Computerized devices from laptops and tablets to smart phones and smart watches use these types of high frequency mixing pressure plate circuit boards. Smartphones usually require about 12 layers. Systems that allow electronic devices such as smart phones, laptops, and GPS devices to operate, such as cell phone towers and satellite technology, also include multi-layer high frequency boards due to the advanced functions required.

The equipment is not as complicated as smart phones and signal towers, but it is too complicated for single-sided printed circuit boards, usually 4 to 8 layers are used. Examples of such products include household products such as microwave ovens and air conditioners, which are increasingly using multilayer technology.

The automotive and aerospace industries are also increasingly using Electronic Components that need to be used simultaneously to be durable and lightweight, making this type of PCB very suitable. These components must be able to withstand wear, heat and other harsh conditions. On-board computers, GPS systems, engine sensors, headlight switches and more components utilize these circuit boards.

PCBs with a large number of layers are also a standard configuration in the industrial industry. More and more industrial machines have computerized components and are usually equipped with sensors, controllers and other components that require PCBs. Due to the harsh conditions of many industrial facilities, this equipment requires advanced features, reliability and durability.