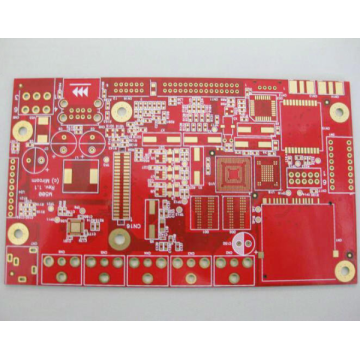

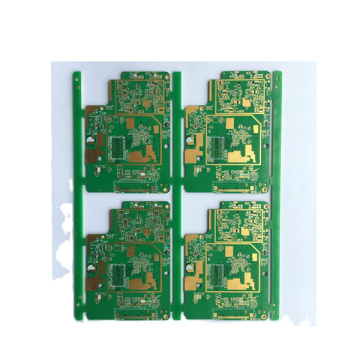

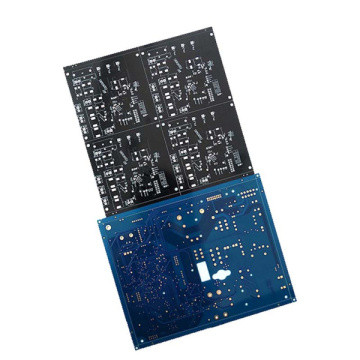

Multilayer PCB 4 Layer PCB Board

-

$0.02≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

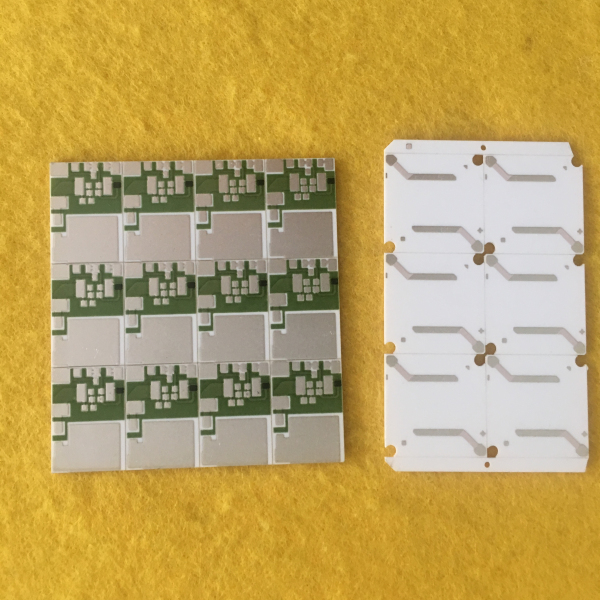

What are the advantages of ceramic circuit boards?

Compared with traditional printed circuit boards (PCB), ceramic circuit boards have many advantages. Due to its high thermal conductivity and minimum coefficient of expansion (CTE), compared with conventional PCBs, ceramic circuit boards have more functions, simpler functions and better performance.

advantage:

1. Excellent thermal conductivity

2. Resistance to chemical corrosion

3. Compatible mechanical strength

4. Easily achieve high-density tracking

5. CTA component compatibility

shortcoming:

1. Cost is higher than standard PCB

2. Reduced availability

3. Fragile handling

high temperature

Perhaps the most popular type of ceramic PCB is the high temperature PCB. Ceramic circuit boards designed for high temperatures are often referred to as high temperature co-fired ceramic (HTCC) circuits. Circuits such as ceramic substrate printed boards are made by mixing adhesives, lubricants, solvents, plasticizers and alumina to make green ceramics.

Use the original ceramic material produced, then coat the material and perform circuit tracking on tungsten or molybdenum metal. After implementation, the circuit is baked at 1600 to 1700 degrees Celsius for 48 hours after lamination. All HTCC baking is carried out in a gas environment, such as hydrogen.

Low temperature

Unlike HTCC, the low-temperature co-fired ceramic PCB is made by mixing the bonding substance on the crystal glass and the metal plate with gold paste. Then, before putting the circuit into a gaseous oven at approximately 900 degrees Celsius, the circuit is cut and laminated.

Low-temperature co-fired ceramic PCBs benefit from less warpage and improved shrink resistance. In other words, they have excellent mechanical strength and thermal conductivity compared to HTCC and other types of ceramic PCBs. When using heat dissipation products such as LED lights, the heat dissipation advantage of LTCC provides an advantage.

Thick film ceramics

Thick-film ceramic circuits include gold and dielectric pastes implemented on ceramic base materials. Once implemented, the paste is baked at 1000 degrees Celsius or lower. Due to the high cost of gold conductive pastes such as ceramics base copper-clad laminates, this type of PCB is popular among major printed circuit board manufacturers.

Compared with traditional PCBs, the main advantage of thick-film ceramic materials is that thick-film ceramics can prevent copper oxidation. Therefore, if ceramic PCB manufacturers are concerned about oxidation, they can benefit from choosing thick-film ceramic circuits.