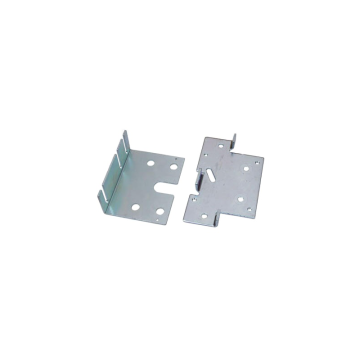

Custom Sheet Metal Stamping Bending Part

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IOS9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

Bergek is a professional sheet metal fabrication and CNC machining manufacturers can customize production CNC, laser cutting, metal stamping, sheet metal bending, sheet metal forming, welding, riveting, etc., Bergek for automotive, industrial, medical, and other services to provide customized metal parts, our high-precision manufacturing equipment and measuring application will guarantee you the quality and delivery.

Bending processing is used in all walks of life, such as building decoration, office equipment, automatic financial cabinet, etc. A lot of things are bent. For bending products, we generally evaluate the quality and quantity of bending parts, quality is divided into size and Angle accuracy, and bending parts surface indentation, scratches, and warping deformation. And quantity means what is productive.

The so-called bending process is the deformation of tensile stress and compressive stress on the front and back of the same plate. After the plate is bent to the desired Angle, once the compression force is removed, the material springs back to its original shape due to both tensile and compressive stresses. We call it bounce-back bending bounce-back.

The amount of spring back in bending processing is generally expressed by the Angle, which will be affected by the material, plate thickness, pressure, bending radius, and other conditions. It is very difficult to calculate exactly the amount of spring back.

Different pressures on the bending material will cause different reaction forces. Once the pressure is removed, the Angle will rebound in a reduced direction. We call this phenomenon a reductive rebound.

CNC bending machine bending processing plate there are many ways, according to the principle of different also have many kinds of classification methods, from the upper and lower mold relative position of different and different bending shape, introduce several common bending methods:

Firstly, according to the different relative positions of the upper and lower dies, the bending process is divided into two forms: gap bending and bottom bending.

The upper die and the lower die are not pressed during bending. The desired bending Angle can be obtained by adjusting the depth of the upper die into the lower die opening. This bending method is called gap bending. The deeper the upper die enters the lower die, the smaller the bending Angle. On the contrary, the bigger. Due to the elastic bending of the material, excessive bending should be considered to control spring back.

The advantage of gap bending processing is that a small number of molds can be used to achieve various angles of forming processing, and the required processing pressure is small.

The bending processing machine presses the plate between the upper and lower die, using the bottom pressing bending, in order to obtain the required bending Angle and elbow radius. CNC bending machine is suitable for batch processing thickness of sheet metal less than 2mm, suitable for mass production enterprises. The bending radius is small, the bending accuracy is high, and the accuracy is good. It should be noted that the working pressure of the bottom bending processing is greater than the working pressure of the gap bending, generally more than three times. The Angle of the bottom bending die should be suitable for the plate Angle and material. Normally, when pressing the bottom bent low carbon steel, the Angle of the upper and lower mold should be consistent with the Angle required for the plate.

Product details

|

Aluminum Alloy

|

AL6061, AL6063, AL6082, AL7075, AL5052, etc.

|

|

Steel

|

Mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45#, etc.

|

|

Iron

|

A3, 45#, 1213, 12L14, 1215, etc.

|

|

Stainless Steel

|

SS201,SS301,SS303, SS304, SS316, SS416, etc.

|

|

Brass

|

HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90, etc.

|

|

Copper

|

C11000,C12000,C12000, C36000, etc.

|

|

Plastic Profile

|

ABS, PC, PE, POM, Nylon, PP, Peek, PTFE etc.

|

|

Steel Sheet Metal

|

Zinc plating, Oxide black, Nickel plating, Chrome plating, Painting, Powder Coated, etc.

|

|

Aluminum Sheet Metal

|

Clear Anodized, Color Anodized, Sandblast Anodized, Powder Coating, Painting, Chemical Film,Brushing,Polishing, etc.

|

|

Stainless Sheet Metal

|

Brush, Polishing, Nickel Plating, Chrome Plating

|

|

Copper & Brass Sheet Metal

|

Brush,

|

Picture case

Often ask questions

What parts can you buy from Bergek?

CNC machining milling parts/turning parts, stamping parts, sheet metal processing parts, bending parts

Why should you buy from Bergek instead of another vendor?

Focus on CNC processing and sheet metal processing, provide CNC turning, CNC milling, stamping bending, sheet metal manufacturing one-stop solution.

Can Bergek make the blueprints for me?

We do not provide design services. You are responsible for submitting 2D and 3D CAD drawings and then we can provide a manufacturing design review upon receipt of your order.

Bergek is a world-class manufacturing service provider in Shenzhen. We have advanced equipment to provide a full range of custom products to manufacturers around the world, focusing on CNC machining and sheet metal processing. Our goal is to make it easier to customize parts. So why not come and see our facilities for yourself? We stand ready to help you bring your next product to market, let us help you succeed! Please contact us with your inquiry.

click request quotation

Related Keywords