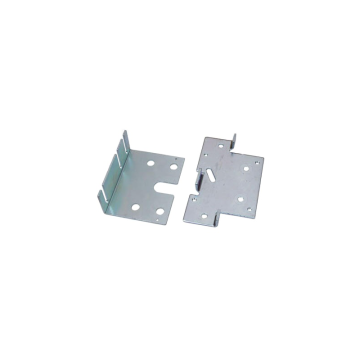

Sheet Metal Bending Process

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IOS9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

Sheet metal bending processing technology in laser cutting, bending, welding/riveting welding, due to the high flexibility of laser cutting, high precision, three-dimensional planning technology to the old and wide, users can benefit from the new planning, new process. Then arrive to reduce the cost, and shorten the duration of the requirements. So the new sheet metal process starts with planning: planning laser cutting, bending, welding/riveting. The following are several examples to illustrate the characteristics of the new process.

1. Under the traditional process, the workpiece is composed of several parts. Now, arrived to cut the process, shorten the construction period, and reduce the cost of the purpose.

2, the traditional process, for welding configuration special fixture. Now the use of similar carpentry tenon technology between components arrived at the purpose of shortening the construction period, reducing costs, and improving quality.

3, because of the use of tenon structure, the workpiece bending after the cooperation spot welding process, can complete the whole process. Small deformation of the workpiece, no need for shaping and polishing before spraying.

4, multiple bending process in the domestic box manufacturing industry has been relatively widespread, eliminating the traditional reinforcement. It has its planning and process together with the local and then arrive at the purpose of high-quality products, low manufacturing cost.

5, the use of laser slit thin, high precision characteristics, a cut, break through the traditional process planning ideas, reached the purpose of shortening the period, reduce the cost. Due to the characteristics of sheet metal welding new process flow, advanced sheet metal processing equipment software support and planning, laser cutting process, bending process. Its supports two-dimensional parts planning, pipe parts planning, sheet metal bending workpiece planning, and three-dimensional graphics open. And the numerical control program is transmitted to the designated machine through the standard computer network.

Product details

|

Picture case

Often ask questions

What parts can you buy from Bergek?

CNC machining milling parts/turning parts, stamping parts, sheet metal processing parts, bending parts

Why should you buy from Bergek instead of another vendor?

Focus on CNC processing and sheet metal processing, provide CNC turning, CNC milling, stamping bending, sheet metal manufacturing one-stop solution.

Can Bergek make the blueprints for me?

We do not provide design services. You are responsible for submitting 2D and 3D CAD drawings and then we can provide a manufacturing design review upon receipt of your order.

Bergek is a world-class manufacturing service provider in Shenzhen. We have advanced equipment to provide a full range of custom products to manufacturers around the world, focusing on CNC machining and sheet metal processing. Our goal is to make it easier to customize parts. So why not come and see our facilities for yourself? We stand ready to help you bring your next product to market, let us help you succeed! Please contact us with your inquiry.

click request quotation