metal injection molding youtube

-

$10.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean

- Port:

- Guangdong, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | shenzhen |

|---|---|

| Productivity: | 1000 |

| Supply Ability: | 1000 |

| Payment Type: | T/T |

| Incoterm: | FOB,EXW |

| Certificate: | ISO9001 |

| HS Code: | Non |

| Transportation: | Ocean |

| Port: | Guangdong,Shenzhen |

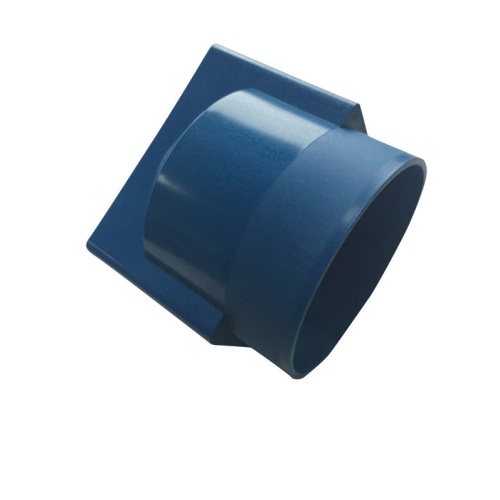

injection molding: The feeding of plastic particles into the part of the hopper at the top of the injection molding machine and the loading of these particles into the main cylinder, where they are heated at high temperatures until they melt into a liquid. Then, inside the injection molding machine, the screw will turn and mix the plastic that has been liquefied. Once the liquid plastic has reached the desired state of the product, the injection process begins, and the plastic liquid is forced through a running gate at a speed and pressure controlled by a screw or plunger, depending on the type of machine used.

Pressure holding: It refers to the process of applying a certain amount of pressure to ensure that each cavity has been completely filled. If the cavity is not filled correctly, it will result in a scrap of the unit.

Cooling: This process step allows the time required for the mold to cool. If this step is performed too hastily, the products may stick together or deform when removed from the machine.

Die opening: The clamping device opens to separate the die. Molds are often reused throughout the process, and they are very expensive to process.

Demoulding: Removing the finished product from the injection molding machine. Generally, the finished product will continue to be packaged and delivered on the production line or as part of a larger product, such as a steering wheel for a car.

In our daily life, each of us uses products that involve injection molding applications every day. If it weren't for injection molding, many cars wouldn't be sold at such an affordable price. However, there are some downsides to this process. These machines are very expensive and therefore require a lot of capital upfront. When designing parts, we must keep the production process in mind, as this process is not economical for short-term production.

However, the speed with which parts are produced, relatively low labor costs, and minimal material waste offset these disadvantages. Even finished parts usually do not require more finishing.

FAQ :

Q: how to contact with sales ?

A: You can send inquiry of our products,it will be replied within 24 hours;

Q: What information should I give to you for inquiry?

A: If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material ,tolerance,surface treatments and the amount you need,ect .

Q: how about certificate?

A: We will make 100% full inspection and provide the inspection reports.

Q: Is it possible to return the money if the quality is not good?

This has never been occured right now ,as we treat the quality as our key of development.Quality and service is everything for us.

Bergek is a world-class manufacturing service provider in Shenzhen. We got advanced equipment to provide all-around customized products for manufacturers around the world, focusing on CNC machining and sheet metal fabrication.