Professional Plastic Injection Molding Custom Service

-

$9.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- guangdong, shenzhen

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | shenzhen |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 10000 |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal,Others |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP |

| Certificate: | IS09001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | guangdong,shenzhen |

Product Description

Product Description

Injection molding by a plunger or reciprocating screw injection into the cavity of closed die forming products plastic processing methods, this method can work with complex shape, size precision or insert products, high production efficiency, most thermoplastics and thermosetting plastics, such as phenolic plastics) are conducted in the processing, used for injection molding materials must have good liquidity, To fill the cavity to get the product.

Product Description:

Professional manufacturers customize injection molding products

1. ODM injection molding, professional manufacturer/service

2. Waterproof and scratch-proof

3. Various shapes, designs, and sizes can be provided according to customer requirements

4. Certification: ISO9001

5. Manufacturer: many years of production experience

6. Low price, high quality, durable and fast delivery

7. Materials: polyethylene, polypropylene, ABS, PE, polystyrene, etc

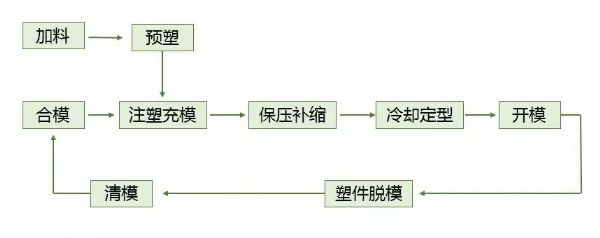

Process flow:

Factors affecting injection molding quality: injection pressure, injection time, injection temperature

Process features:

(1) Short molding cycle, high production efficiency, easy to achieve automation

(2) It can form plastic parts with complex shapes, precise size, and metal or non-metal inserts

(3) Stable product quality

(4) Wide range of adaptation

Application scenarios:

Among industrial products, injection molding products include kitchen products (garbage cans, bowls, buckets, POTS, tableware, and various containers), electrical equipment shells (hairdryers, vacuum cleaners, food mixers, etc.), toys and games, various products of the automobile industry, parts of many other products, etc.

Product case picture:

End: Merchants who need customized products can send drawings to szbergek for quotation

click request quotation

Related Keywords

Related Keywords

Custom Plastic Plastic Injection Molding Parts , Custom Plastic Mold Injection Molding Parts , High Quality Injection Molding Machinery

Custom Plastic Plastic Injection Molding Parts , Custom Plastic Mold Injection Molding Parts , High Quality Injection Molding Machinery