Large Capacity Belt Filter Press for Sludge Dewatering

-

$4000.00≥1000 Set/Sets

- Min. Order:

- 1000 Set/Sets

- Min. Order:

- 1000 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Tianjian, Tianjian

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 3000sets/year |

| Supply Ability: | 3000sets/year |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,FAS,FCA |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Tianjian,Tianjian |

Large Processing Capacity Belt Filter Press for Sludge Dewatering

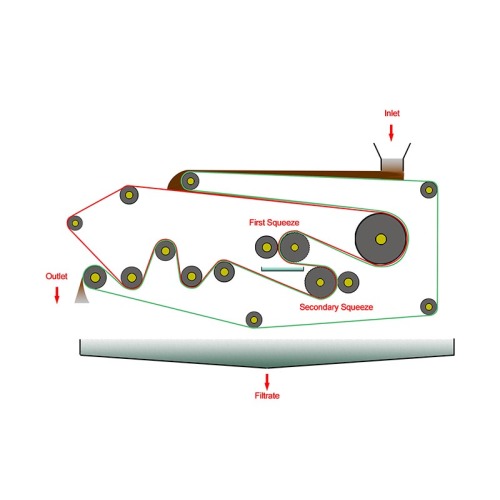

Belt filter press is a new generation of dehydration equipment, it has the advantages of large processing capacity, high dehydration efficiency (from the slurry concentration of 0.8-3% can be directly increased to more than 28-35%), low energy consumption,etc. The belt filter press not only solves the problem of running material when the conventional filter press dehydrates the raw material, but also solves the problem of low material pressure at both ends of the filter screen. Because the new model has a pre-dewatering network case, the natural gravity dewatering area of the sludge is lengthened, and the Internet is not squeezed, the mesh is not easy to be blocked by fiber, sludge. So compared with the traditional filter press, its advantages come out. It can reduce the amount of mesh belt and amide by more than 10-30%, and the structure is simple, easy to install, is the ideal product of sludge pressure filtration, dehydration. Belt filter press can be widely used in urban sewage, printing and dyeing, textile, papermaking, food, pharmaceutical, chemical, metallurgy, petroleum and other fields of sludge (or material) dehydration.

Working Principle

The material passes through the conveyor, transported to the hopper of the dewatering machine, and evenly laid on the filter belt through the auger. The filter belt is leveled by the height of the material layer with the operation of the equipment so that the thickness of the material is completely uniform. Then, the upper and lower two ring-shaped filter belts are completely clamped, and the material layer is clamped by the driving roller, and the pair of rollers in the dewatering zone is mechanically pressed several times to press out a large amount of water. According to the characteristics of the material, the extrusion force is automatically adjusted to meet the customer's requirements for material moisture.

Features of Belt filter press

1. It adopts advanced technology and has good appearance. The structure has a large stiffness, a steady operation and low noise.2. It is equipped with advanced concentration preprocessing equipment to flocculate slurry preferably and decrease running cost.

3. Gravity dewatering zone is equipped with advanced distributor to scatter material uniformly and extend filter cloth service life. Long wedge-shaped dewatering zone and gravity dewatering zone to dehydrate material sufficiently, and make sure that material will not overflow.

4. Dewatering rollers are arranged in a scientific way. Filtrate is respectively discharged from gravity zone, wedge-shaped zone and squeezing zone without disturbing each other. .

5. It works continuously from feeding to cake discharging. It has high degree in automation. PLC interface can be installed as needed to realize centralized control by computer.

6. Power transmission adopts mechanical or frequency step-less speed regulation, so as to get wide speed range and application spectrum.

7. Each belt is equipped with pneumatic tensioning and auto rectifying system to ensure safe operation of filter belt.

Related Keywords