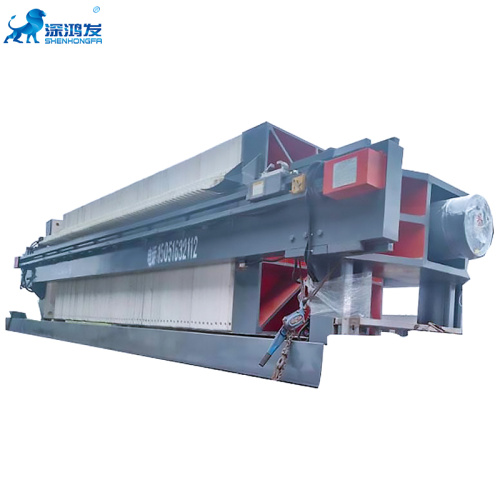

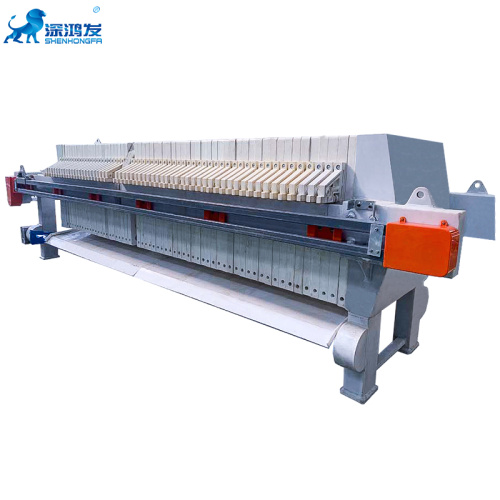

Automatic Chamber Membrane Filter Press System

-

$6000.001-2 Set/Sets

-

$5400.00≥3 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- shenzhen, qingdao

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | china |

|---|---|

| Productivity: | 5000sets/year |

| Supply Ability: | 5000sets/year |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CIF,EXW,DDP,DDU,Express Delivery |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 8421291090 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | shenzhen,qingdao |

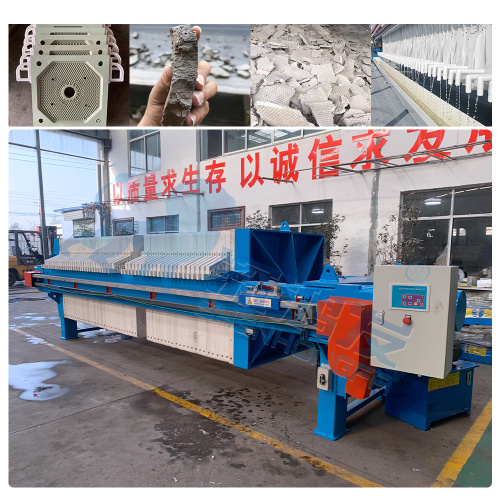

Q: What are the daily maintenance of plate and frame filter press? A: In the sand and stone system wastewater treatment, the filter press is commonly used as the end mechanical treatment mode of solid-liquid separation, the material is filtered through pressure, especially for the separation of viscoses, which has its unique advantages. So what about the daily maintenance of the filter press? 1, often keep the hydraulic system clean and stable, to prevent other sundry immersion caused by failure. 2. In the press filtration process, the press cloth should be kept flat, no folds are allowed, and the press cloth should be cleaned according to the situation. 3, often check the press cloth, if there is a leak, timely replacement, repair. When mending the press cloth, the broken part should be cut off and then mended to prevent overlap on the sealing surface and increase the thickness of the press cloth. 4. Regularly inject grease into the bearing, spray oil to the transmission chain and track of the equipment, and remove dirt. Q: Cause plate and frame filter press work stop reason: if the plate and frame filter press control system error will cause plate and frame filter press equipment to stop working, it is known that when working, the control system needs to use to control the hydraulic system, plate and frame filter press equipment control system directly affects the filtration of filtrate what causes. When there is an error in the control system, or can not send out the control hydraulic system understanding, or the control system can not sense the condition of the hydraulic system, naturally, this is the plate and frame filter press equipment can not work, even if it is reluctantly run up is very dangerous, so the work of the equipment needs to be stopped in time. The reason why plate and frame filter press stops working may be that the flow path in the equipment is blocked. Q: The outstanding advantages of plate and frame filter press: Plate frame filter press is composed of diaphragm filter plate (diaphragm filter plate is made of two pieces of polypropylene diaphragm and high strength polypropylene core plate thermal fusion) and box filter plate arranged to form a filter chamber, under the pressure of the feed pump will feed the slurry into the filter chamber, through the filter cloth to separate the solid and liquid in the slurry, when the solid in the slurry formed cake, and then inject appropriate pressure air into the diaphragm filter chamber. Fully press solids in the filter chamber to reduce water content. Especially for the viscous material filtration and high water content requirements of the user, this machine has its unique characteristics.

Related Keywords