Haircell Textured Finish ABS Sheet

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | Enough |

|---|---|

| Payment Type: | T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Certificate: | SGS RoHS Reach ISO9001 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen,Guangzhou,Hongkong |

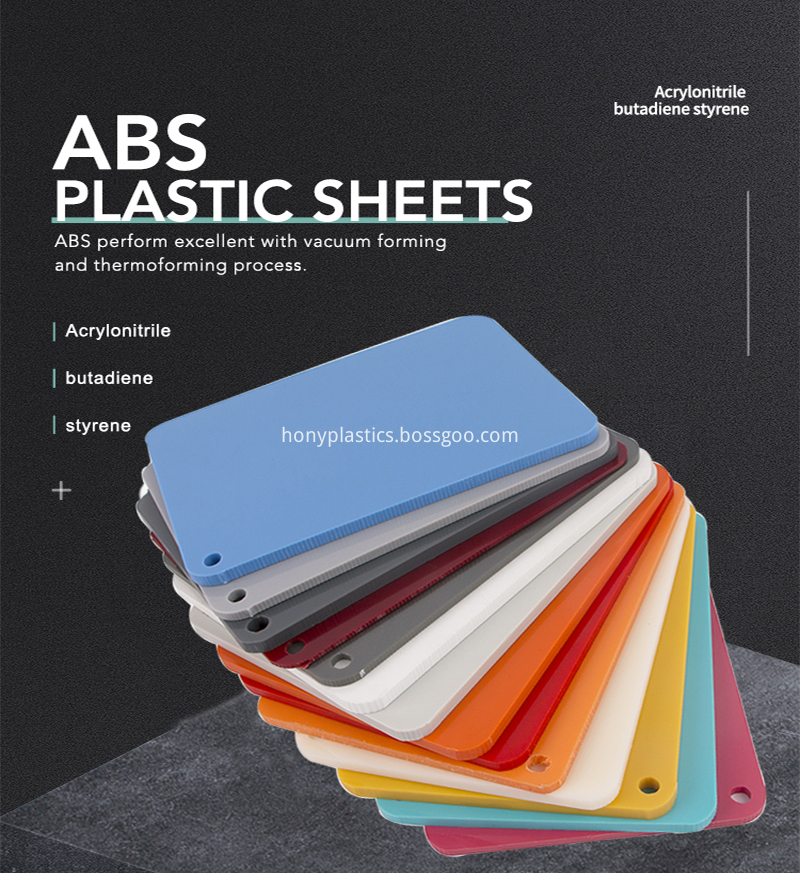

HONYcSmooth Textured Plastic ABS Acrylonitrile Butadiene Styrene Panel Board Sheet m0.2 to 10mm texture ABS Plastic sheet High gloss ABS Plastic board for thermoforming,ABS is the most excellent in mixing raw materials.We strictly control every layer from raw materials to extruded board, there must be no slight error.In order to meet the needs of customers to adapt to the market, we provide a variety of different materials. And the board also has special treatment, such as smooth, matte, texture,wood grain and so on. These products meet quality standards.

ABS Plastic Rods Produce

ABS Plastic Sheet

Color

White, Black, Red, Blue, Green, Yellow, and customized

Width

≤1200mm

Length

Customized

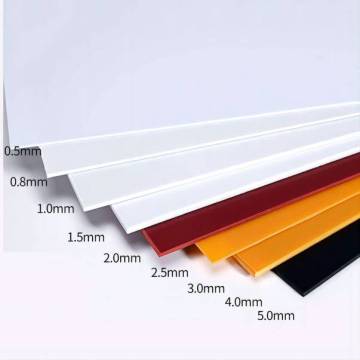

Thickness

0.3-3MM

Density

1.06g/cm3

Surface Type

High Glossy, Smooth, rough, texture

Special requirements

Fire-retardant, UV resistant, Food Grade, Anti-static

ABS Sheet and Plate Feature:

High rigidity

Good impact resistance, even at low temperatures

Good insulating properties

Good weldability

Good abrasion and strain resistance

High dimensional stability (Mechanically strong and stable over time)

High surface brightness and excellent surface aspect

Excellent mechanical properties

Good resistance to dilute acid and alkalis

ABS Plastic Rods Application:

· Automotive parts

· instruments

· sports equipment

· gardening

· medical applications

· packaging

· luggage and handbag

· machinery parts

| HONY®ABS Technical Data Sheet |

|

|

|

| Property item | Testing method | Unit | Testing data |

|

Mechanical properties |

|||

| Density | ASTM D792 | g/cm3 | 1.13 |

|

Tensile strength at yield |

ASTM D638 | Mpa | 59 |

|

Elongation at break |

ASTM D638 | % | 54 |

|

Bending strength |

ASTM 790 | Mpa | 65 |

|

Flexural modulus |

ASTM 790 | Mpa | 2300 |

|

Shore Hardness |

ASTM D2240 | D | 83 |

|

Impact strength |

ASTM D256 | J/M | 300 |

|

Thermal performance |

|||

|

Melting point |

DSC | ℃ | 180 |

|

Heat distortion temperature |

ASTM D648 | ℃ | 90 |

|

Long-term working temperature |

- | ℃ | 90 |

|

Short-term working temperature |

- | ℃ | 120 |

|

Thermal conductivity |

DIN 52612-1 | W/(K-M) | 0.17 |

|

Coefficient of linear expansion |

ASTM D696 | 10-5-1/K | 9 |

|

Electrical properties |

|||

|

Dielectric strength |

ASTM D150 | KV-mm | 23 |

|

Dielectric loss coefficient |

ASTM D150 | - | 0.015 |

|

Volume resistance |

ASTM D257 | Ω.cm |

10^15

|

|

Surface resistance |

ASTM D257 | Ω | 10^14 |

|

Dielectric constant |

ASTM D149 | - | 3.3 |

|

Chemical properties |

|||

|

Balanced water absorption |

23℃ 60%RH | % | 0.4 |

|

Acid resistance |

23℃ 60%RH |

|

+ |

|

Alkali resistance |

|

|

0 |

|

Acid and alkali water resistance |

|

|

+ |

|

Chloric acid and alkali resistance |

|

|

0 |

|

Resistant to aromatic compounds |

|

|

- |

|

Copper resistance |

23℃ 60%RH |

|

- |

|

Hot water resistance |

23℃ 60%RH |

|

0 |

|

Other properties |

|||

|

Combustibility |

UL 94 |

|

HB |

|

Stickiness |

|

|

+ |

|

toxic free and safe |

EEC 90/128 FDA |

|

0 |

|

Coefficient of friction |

DIN 53375 |

|

0.5 |

|

anti-UV |

- |

|

- |

Remark:

1."+" Tolerable , “-”Intolerable , "0" Depends on the situation

2. The above data is obtained from raw material test data, which is not completely consistent with the performance of the finished product, and the uniqueness of the data is not guaranteed

ABS processing part Main product

Package

Related Keywords