Fr4 G10 Epoxy Fiber glass Tube

- Min. Order:

- 1

- Min. Order:

- 1

- Transportation:

- Land, Ocean, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 10000 |

|---|---|

| Transportation: | Land,Ocean,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

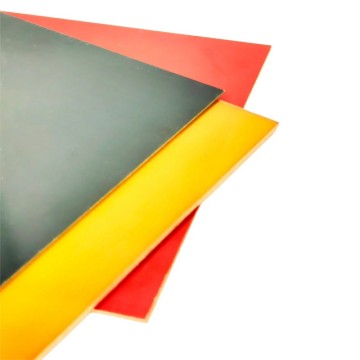

FR4 sheet vs. other materials: A “personality contest” in the world of electronic materials

In the vast world of electronic manufacturing, a variety of materials as if a group of distinctive “players”, in different areas to show their advantages. FR4 sheet as one of the “star player”, with its unique performance in PCB manufacturing and other fields occupies an important position. However, compared with other materials, it has what difference? Let's unveil this electronic materials sector “personality contest” of the veil.

First, the material composition and structure of the differences

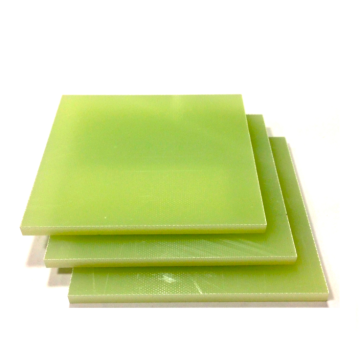

FR4 board: glass fiber cloth and epoxy resin “perfect partner”

FR4 board is mainly made of glass fiber cloth impregnated with epoxy resin after hot pressing. The glass fiber cloth is like its “skeleton”, giving the board good mechanical properties and dimensional stability; while the epoxy resin is like an “adhesive”, which combines the glass fiber cloth tightly, while also providing a certain degree of electrical insulation properties. This unique composition and structure makes FR4 boards have high strength and rigidity, like a strong athlete, able to withstand certain external forces and not easy to deform.

For example, in the PCBs of some electronic products, FR4 boards can provide stable support for electronic components to ensure that their performance will not be affected by deformation of the board during long-term use.

Comparison with paper substrates: “soft” versus “strong”

Paper substrates are usually made of wood pulp paper or cotton fiber paper impregnated with phenolic resin. Compared to FR4 boards, paper substrates are like a “weak dancer”, with low mechanical strength and susceptible to deformation by moisture. In a humid environment, the insulating properties of paper substrate materials will be significantly reduced, and may even lead to problems such as short circuits.

The FR4 board, due to its structure of glass fiber cloth and epoxy resin, has better moisture resistance and insulation stability, and is able to work properly in a more hostile environment. Therefore, in the mechanical properties and moisture-proof performance requirements of higher occasions, FR4 board is significantly better than paper substrate materials.

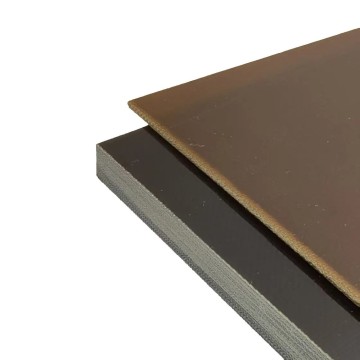

Comparison with metal substrate materials: insulation and thermal conductivity of different focuses

Metal substrate materials are generally based on aluminum, copper and other metals as a substrate, covered with an insulating layer. The biggest advantage of metal substrate material is its good thermal conductivity, like an efficient “heat dissipation expert”, which can quickly dissipate the heat generated by electronic components.

In contrast, FR4 sheet has poor thermal conductivity, but its insulating properties are excellent. In some of the very high insulation requirements of electronic equipment, such as high-voltage power supplies, communications equipment, etc., FR4 sheet is a better choice; and in the need for rapid heat dissipation occasions, such as LED lighting, power modules, etc., metal substrate materials are more advantageous.

Second, the difference between the electrical properties

Dielectric constant and loss factor: signal transmission of the “invisible bridge”

Dielectric constant and loss factor is an important indicator of the electrical properties of the material. FR4 sheet dielectric constant is generally between 4.0 - 4.8, loss factor in the 0.01 - 0.02. This makes the FR4 sheet in low temperature, low temperature, low temperature, low temperature, low temperature, low temperature, low temperature, low temperature, low temperature, low temperature, low temperature, low temperature, low temperature, low temperature, low temperature. This makes FR4 sheet perform well in low-frequency signal transmission, effectively minimizing signal attenuation and distortion, and acting as a sturdy bridge to ensure that signals can pass through smoothly.

However, in high frequency signal transmission, the dielectric constant and loss factor of FR4 sheet changes as the frequency increases, resulting in increased signal attenuation and distortion. In contrast, some high-frequency materials, such as polytetrafluoroethylene (PTFE) materials, have lower dielectric constants and loss factors and perform better in high-frequency signal transmission.

A comparison of the performance of different materials in high-frequency signal transmission is shown below:

Insulation Resistance: The “Guardian” of Circuit Safety

Insulation resistance is an important indicator of a material's insulating properties.FR4 sheet has high insulation resistance, which can effectively prevent current leakage and protect the safe operation of electronic equipment. It is like a loyal “guard”, guarding the safety of the circuit.

And some conductive materials, such as metal materials, itself has good electrical conductivity, does not have insulation properties. In the need for insulation in electronic equipment, must be used to isolate the insulating material, FR4 sheet is a good choice.

Third, the mechanical properties and processing performance differences

Mechanical strength and flexibility: “just” and “soft” competition

FR4 sheet has high mechanical strength and rigidity, can withstand certain external forces and pressure. In some electronic devices that require structural support, FR4 sheet can provide a stable foundation. However, its low flexibility makes it unsuitable for applications that require bending or folding.

In contrast, some flexible materials, such as polyimide (PI) materials, have good flexibility and bendability and can accommodate a variety of complex shapes and structures. Flexible materials are more advantageous in areas such as wearable devices and flexible displays.

Processing performance: the “fitness” of the manufacturing process

FR4 boards have good processing performance and are easy to cut, drill, etch and other processing processes. It can be produced through the conventional PCB manufacturing process, the production efficiency is high. It is like an “all-rounder” that can adapt to the requirements of various manufacturing processes.

Some special materials, such as ceramic materials, are difficult to process due to their high hardness, requiring special processing techniques and equipment, with relatively low production efficiency. Therefore, in large-scale production, FR4 sheet processing advantages are more obvious.

Fourth, the difference between cost and application areas

Cost: cost-effective “scales”

The cost of FR4 sheet is relatively low, with a high price-performance ratio. This makes it widely used in the field of electronics manufacturing, has become the material of choice for most PCB manufacturing. Like a good value for money commodity, favored by the majority of consumers.

Some high-performance special materials, such as high-frequency materials, ceramic materials, etc., due to its high raw material costs and manufacturing process costs, the price is relatively expensive. In the more cost-sensitive applications, FR4 sheet is more competitive.

Related Keywords

Related Keywords