Insert Molding Technologies for Automotive Industry

$5000.00 - $30000.00/Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Payment Type: | T/T |

|---|

Product Description

Product Description

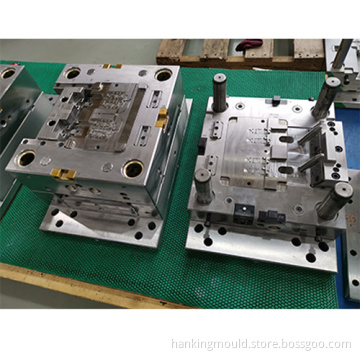

Mould Type: Automotive Sensor Plastic Injection Mould

Production Material: Nylon PA66

No of Cavities: 4 cavities

Core Material: S7

Cavity Material: S7

Mold base steel: 1.1730 with A/B plate 1.2312

Injection System: Cold runner

Type of gating: sub gate

Ejection system: Round ejector pins

Lead time: 6 weeks

Shot life: 1,000,000

Export to: America

Feature: 2 times over molding

Excellent mould design and tool construction are very important in injection moulding to keep tooling reliability and part tolerances.

In HanKing Mould, a project manager control your plastic parts project from concept tooling design to delivery, our project manager has both design and project management experience, the project manager will connect customer and every work phase from design confirmation, mould building, insert molding trial, low volume production, etc.

HanKing mould manufacturing China

Plates and Mold Base Components: ± 0.013 mm (± 0.0005 in)

Cavity components: ± 0.005 mm (± 0.0002 in)

Contact us for more information about insert molding technologies!