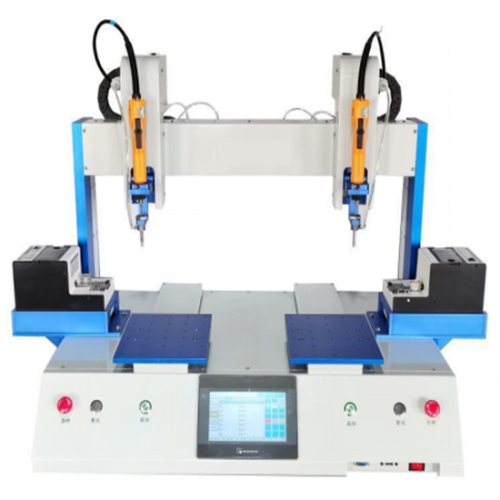

Desktop electric automatic locking screw machine

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen, China |

|---|---|

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Port: | Shenzhen |

Product Show

Specifications:

|

Running range |

Dual X300* Dual Y300*Dual Z100 (mm) |

|

Max moving speed |

1200mm |

|

Repeat accuracy |

±0.02mm |

|

Dimension |

590(L)×860(W)×730(H) (mm) |

|

Max load |

10KG |

|

Electric batch |

Servo electric batch(standard) |

|

Control system |

constant control system+touch screen |

|

Edit mode |

Touch screen + handheld programme |

|

Applicable screw |

M0.6-M6.0mm |

|

Display way |

Human Machine Interface |

|

Locking time |

0.6s-2s |

|

Program recording mode |

999 groups |

|

External Control Interface |

RS232/USB |

|

Input voltage |

AC220V/ 50-60HZ |

|

Net weight |

150KG |

Product Features

1. With double Y axis operating platform, the operator can feed and receive materials alternately and feed materials continuously to save labor cost and improve production efficiency.

2. Adopt double screw batches and feeders to work at the same time to achieve more fast locking speed and higher production efficiency.

3. Adopt closed loop motor + Taiwan silver linear guide drive, so the running speed is very high, and the max speed can be 1200mm/s.

4. With the strong versatility, the locking path can be designed according to the screw position situation, and multiple schemes can be stored. Switching to the corresponding scheme can be used in different products.

5. With automatic alarm function, when the screw is not absorbed, screw sliding teeth or floating phenomenon, machine can automatically check and alarm ,it won’t let bad screws flow down to ensure product quality.

6. The main parts of the machine use imported spare parts with the precise positioning and high precision lock.

7. The body material is made of steel plate + aluminum alloy, which makes the machine is more firm and has higher lock stability.

8. With touch screen editor control, more simple and convenient operation, it’s easy to learn and understand.

9. With vacuum negative pressure method to automatically adsorb screws, and equipped with constant control professional screw system, the machine is with the powerful function and stable performance.

10. Fixtures will be designed strictly according to the products . The positioning is accurate and it’s easy to replace the fixtures.

11. The machine can work continuously and stably every day, and suit for the mass production.

Application scene:

Suitable for toys, electronic products (mobile phone, hard drive, keyboard, mouse, charger etc..) ,Plastic mold, communication equipment, LED lighting, auto parts, household appliances, hardware processing industry, etc..