Choose PSA Oxygen Generator or VPSA Oxygen Generator

- Min. Order:

- 1 Others

- Min. Order:

- 1 Others

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Supply Ability: | strong |

| Payment Type: | T/T |

| Incoterm: | FOB,CIF,EXW |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

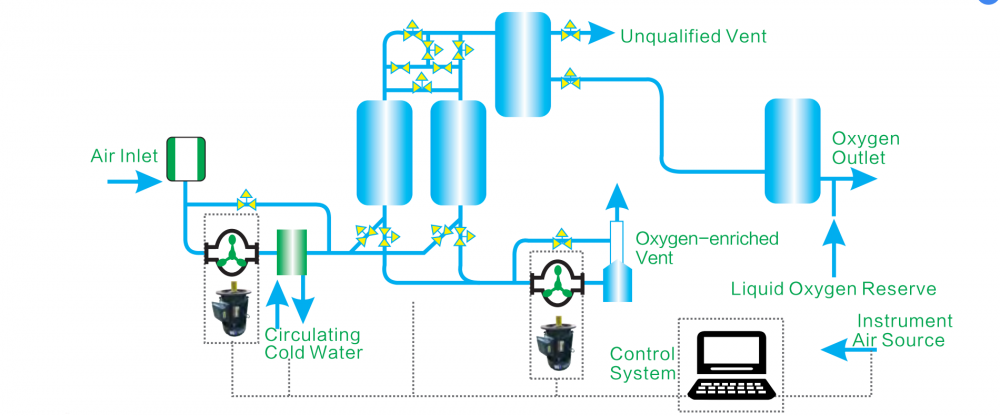

VPSA Oxygen Generator is mainly composed of blower, vacuum pump, switching valve, adsorber and oxygen buffer tank. After the raw air passes through the suction inlet filter to remove dust particles, it is pressurized by the Roots blower at 30-50KPa and enters one of the adsorption towers. Then the nitrogen is filled in the activated alumina for adsorption, and then the nitrogen is filled in the active oxidation Adsorbed by the zeolite molecular sieve on the upper part of the aluminum. Oxygen (including argon) is a non-adsorbed component and is discharged to the oxygen buffer tank from the outlet at the top of the adsorber as a product. When the adsorber is adsorbed to a certain extent, the adsorbent in it will reach a saturated state. At this time, the vacuum pump is used to evacuate it through the switching valve (opposite to the adsorption direction), and the vacuum degree is 60-75Pa. The adsorbed moisture, carbon dioxide, nitrogen and a small amount of other gas components are pumped out and discharged until they are aligned, and the adsorbent is regenerated.

Oxygen is an important industrial gas, widely used in iron and steel, nonferrous metallurgy, chemical industry, furnace energy saving, environmental protection (sewage treatment, garbage incineration, etc.), glass, papermaking, medical treatment and other industries. Lithium molecular sieve adsorbents appeared in the 1990s, and pressure swing adsorption Oxygen Separation Plant rapidly developed into a new low-cost oxygen production technology and began to be widely used.

VPSA Oxygen / Nitrogen Generator

1. The energy consumption is relatively low. The greater the oxygen production, the lower the energy consumption.

2. Low maintenance cost. The moving equipment is Roots blower and Roots vacuum pump. Because of their working principle, they are volumetric, oil-free, and easy to maintain.

3. The whole set of equipment has a high degree of automation. The driving equipment and the oxygen generator are controlled synchronously. Just press the start button, and the whole set of equipment can run normally.

4. Suitable for medium and large output.