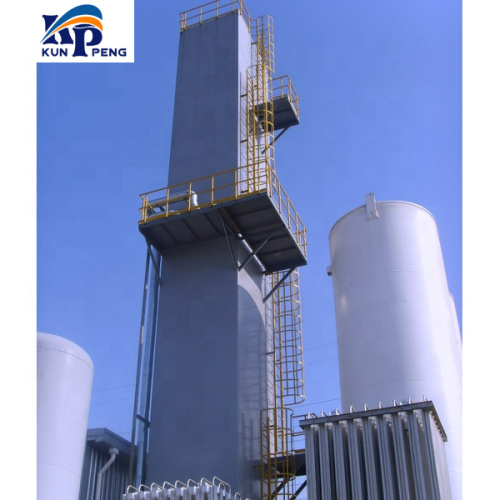

Air Separation Unit High Purity Nitrogen Plant

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- Shenzhen, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T,Others |

|---|---|

| Incoterm: | FOB,CIF,EXW |

| Transportation: | Ocean |

| Port: | Shenzhen,Shanghai |

KPDN High Purity Nitrogen Air Separation Unit

Our nitrogen equipment can adoptforward flow and reverse flow, single-tower,double-tower and other process organization methods to meet the requirements of different pressure levels of customers. The whole devicecan be controlled by DCS or PLC system.

What is ASU

Following your specific require to design the machine, liquid phase or gaseous phase, the production of each product. Full set production line which is automatic.Liquid air separation equipment requires more cooling capacity than gas air separation equipment.

Working Principle

The basic principle of air separation is use cryogenic rectification to condense air into liquid and separate the air according to the evaporation temperature of each component. The two-stage rectification tower simultaneously obtains pure nitrogen and pure oxygen at the top and bottom of the upper tower. It is also possible to take out liquid oxygen and liquid nitrogen from the evaporation side and the condensation side of the main cooling respectively. The air separation in the rectification tower is divided into two stages, air is separated for the first time in the lower tower to obtain liquid nitrogen and at the same time obtain oxygen-enriched liquid air. The oxygen-enriched liquid air is sent to the upper tower for rectification to obtain pure oxygen and pure nitrogen. The upper tower is divided into two sections: with the liquid-air inlet as the boundary, the upper part is the rectification section, which rectifies the rising gas, recovers the oxygen component, and purifies the nitrogen purity, and the lower section is the stripping section to remove the nitrogen components in the liquid, separated to improve the oxygen purity of the liquid.

Products Information -Air Separation Plants

Specifications for classification

FAQ

Q1. What is your main product ?

A: Oxygen gas plant , nitrogen gas plant , liquid oxygen plant , liquid nitrogen plant , special gas plant ...

Q2. What is your terms of payment?

A: T/T . Welcome to inspect the products

before you pay the balance.

Q3. What is your terms of delivery?

A: FOB

Q4. How about your delivery time?

A: Generally, it will take 60 to 90 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the client's request ?

A: Yes, we can produce by your request or technical drawings. We can build the molds and fixtures.

Q6: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

For more details please contact me , Welcome to visit our factory

Related Keywords