Liquid O2/N2 Generation Plant/Gas Production Equipment

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T |

|---|---|

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

Product Description

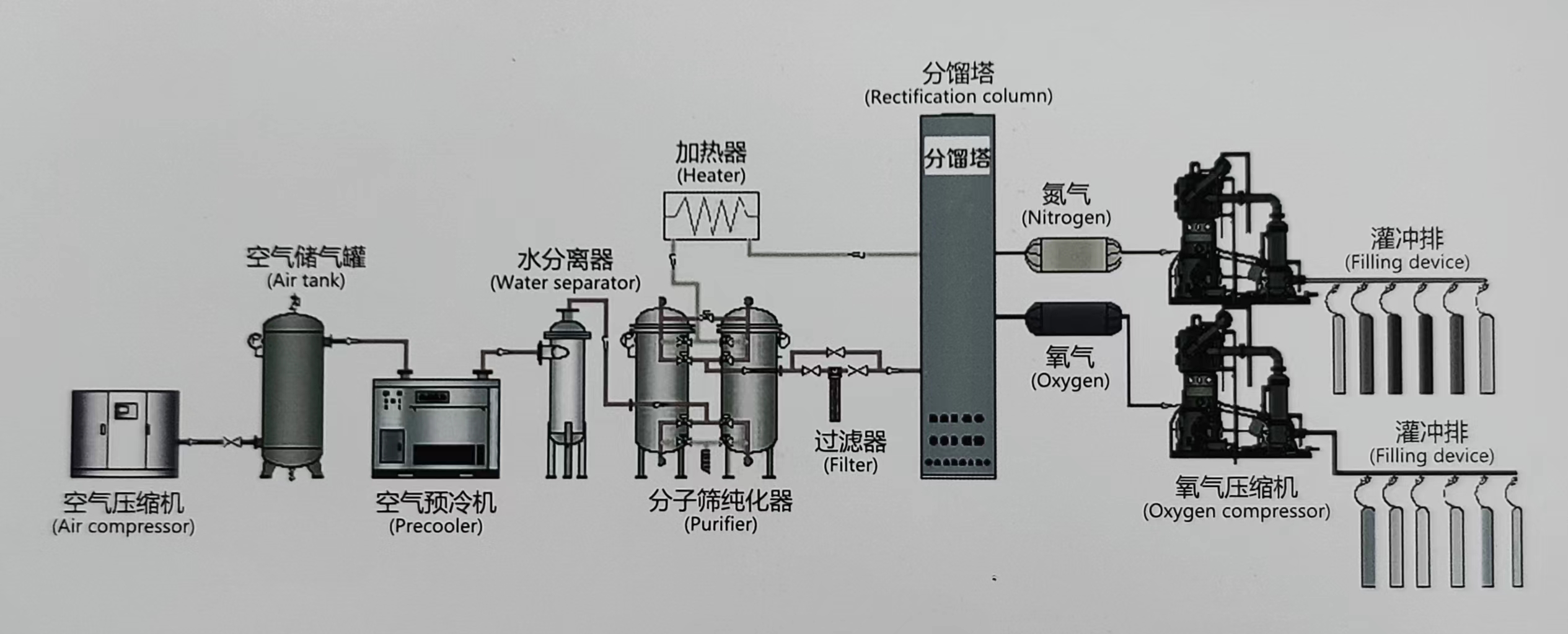

The whole process consists of air compression and purification, air separation, and gas filling station.

Process Description

Oxygen Separation Plant(KDO)

Name

Oxygen

Pressure

20MPaG(adjustable)

Purity

≥99.6%

Operation Cycle

12months

Start time

~24hours

Single column, internal compression process

Cryogenic Air Separation Oxygen and Nitrogen Plant(KDON)

Name

Oxygen&Nitrogen gas

Pressure

20MpaG(adjustable)

Oxygen purity

≥99.6%

Nitrogen purity

≥99.99%

Start pressure

1.0MPaG

Double column, external compression process

Main Equipment of Air Separation Unit:

Product Advantages Asu Plant

1. The compact and modular design of all systems ensures easy transportation and cheaper installation, fast project delivery time seamlessly connects with the customer team, minimizes project costs and optimizes project schedules.

2. Fully automated system for simple and reliable operation.

3. Guaranteed availablity of high-purity industrial gases.

4. Guaranteed by the availability of product in liquid phase to be stored for use during any maintenance operations.

5. Low energy consumption, simple installation and maintenance

6. Short time delivery, seamless operation with one team together with the clients to minimize project cost and optimize the proposal.

Whether you are producing steel or nonferrous metals, traditional petrochemicals, or running the most advanced gasification or oxy-fuel process for your clean energy application, your air separation plant plays a significant role in your operations. Our company has the technology, experience, and resources necessary to design, engineer, construct, and operate a cost-effective gas supply system for your specific application.

Related Keywords